When comparing a lowboy vs RGN, it boils down to one critical, actionable difference: how you get equipment onto the trailer. A Removable Gooseneck (RGN) trailer has a front section that detaches, allowing the trailer deck to drop to the ground and form a simple, drive-on ramp. In contrast, a standard fixed-neck lowboy is a solid unit that requires a crane or separate ramps for loading.

Understanding the Heavy Haul Trailer Landscape

Choosing the right trailer is a critical decision in heavy haul logistics that directly impacts project safety, efficiency, and your bottom line. To make the right call, you must look past basic specs and analyze the core design, how it integrates into your operational workflow, and the true cost implications. The choice between a lowboy and an RGN trailer fundamentally dictates how a job will be executed from start to finish.

This need for specialized transport solutions is reflected in market data. The global lowboy trailer market has grown to USD 2.41 billion, driven by large-scale infrastructure projects and high demand from the construction and mining sectors. You can learn more about the lowboy trailer market trends for deeper insights.

Core Differences at a Glance

To clarify the lowboy vs RGN debate, focus on their primary operational strengths. An RGN is the undisputed champion for any equipment that can move under its own power, especially machines with very low ground clearance. It provides a safe, low-angle ramp that simplifies loading.

A standard lowboy is often the more practical, cost-effective choice for static cargo that must be crane-loaded or for vehicles that can safely navigate a steeper loading angle.

Key Takeaway: The goal isn't to determine which trailer is "better," but which is the correct tool for the job, precisely matched to your cargo's dimensions, weight, and mobility to ensure a successful transport.

This guide provides a clear framework to help you decide which trailer is the most effective—and profitable—choice for your specific transport needs.

| Feature | Standard Lowboy Trailer | Removable Gooseneck (RGN) Trailer |

|---|---|---|

| Loading Method | Crane-loaded or via rear ramps | Front-loading via detachable neck |

| Best For | Static cargo, high-clearance vehicles | Self-propelled, low-clearance equipment |

| Complexity | Simple, fixed one-piece design | More complex with hydraulic/mechanical systems |

| Cost Profile | Lower initial cost and maintenance | Higher initial cost and maintenance |

Understanding Core Design and Functionality

Before choosing between a lowboy and an RGN, it’s essential to understand how their construction impacts operations. Their engineering directly affects loading procedures, hauling capacity, and overall job site safety.

A standard lowboy is a workhorse, built as a single, solid unit. Its defining feature is a fixed gooseneck permanently welded to the trailer frame. This one-piece design provides exceptional structural strength and creates a two-level deck, which lowers the center of gravity for a stable ride.

The main loading area, or "well," is designed to be extremely low, typically sitting just 18 to 24 inches off the ground. This low profile is critical for clearing bridges and power lines with tall loads, often preventing the need for special permits and complex rerouting. However, because the gooseneck is fixed, loading options are limited to either craning equipment on or driving it up ramps from the rear.

The Removable Gooseneck Advantage

The RGN trailer operates on a more flexible concept. Its standout feature is a gooseneck that detaches from the main trailer body, typically via hydraulics. This design gives the RGN a significant advantage for specific types of heavy equipment.

Once the gooseneck is detached, the front of the trailer drops directly to the ground. This action transforms the front of the trailer into a wide, gently sloped ramp, allowing operators to drive equipment straight onto the deck without separate ramps, cranes, or winches. It's a faster and safer loading method. For a deeper dive, our guide on RGN trailer transport covers these specifics.

Key Insight: The RGN's ability to become its own ramp is its biggest operational advantage. It eliminates the risks and logistical challenges associated with using cranes or maneuvering heavy machinery up steep, narrow ramps.

This ground-level access is non-negotiable for equipment with minimal ground clearance, such as asphalt pavers and milling machines, that would bottom out on standard ramps. The decision is not about which trailer is superior, but about which loading style is appropriate and safe for your specific machine.

A Head-to-Head Operational Comparison

When deciding between a lowboy and an RGN, the operational realities are what matter most. This choice directly impacts loading times, job site safety, and the need for auxiliary support equipment, which can disrupt project schedules and budgets. The core difference is how your cargo gets onto the trailer.

A standard lowboy’s fixed-neck design is simple and robust, but this simplicity has a drawback. Loading often becomes a significant operation, requiring external equipment like a crane, forklift, or winch. This not only adds rental costs but also introduces complexity and potential delays if that equipment isn't readily available.

For self-propelled equipment, loading a fixed-neck lowboy involves a high-risk maneuver up steep, often narrow, rear-mounted ramps. This increases the chance of the machine tipping or becoming misaligned, demanding a highly skilled operator and a spotter for safety.

The RGN Advantage in Speed and Safety

The Removable Gooseneck (RGN) trailer fundamentally changes the loading process. By detaching the gooseneck, the front of the trailer deck lowers to the ground, creating a full-width, low-angle ramp. For any wheeled or tracked equipment, this drive-on capability is a significant operational advantage.

Consider loading an excavator. With an RGN, it's a simple matter of driving it directly onto the deck. This is dramatically faster, often reducing loading and unloading times by over 50% compared to the slow, precise process required for a standard lowboy.

Operational Insight: The RGN's ground-level loading capability doesn't just save time—it's a massive improvement in operator safety. It eliminates the precarious task of climbing steep ramps and removes the need for crew members to work under heavy, crane-lifted loads.

This efficiency is invaluable on a busy job site where every minute translates to cost. A faster turnaround means your equipment gets to work sooner, boosting productivity and reducing idle time for the transport crew.

Versatility and Finding the Right Fit for Your Cargo

While the RGN is the clear winner for mobile equipment, the standard lowboy remains essential for its versatility with static cargo. Its simple, open-deck design is ideal for items that require crane loading, such as industrial generators, large-diameter pipes, or prefabricated steel beams. In these cases, the RGN's detachable neck offers no advantage and only adds unnecessary weight and complexity.

For instance, when moving a large, crated industrial machine, a lowboy provides a straightforward, stable platform for a crane. Using an RGN for the same task would be inefficient. For non-mobile cargo, the lowboy is almost always the more practical and cost-effective solution. This same logic applies to other specialty trailers, as covered in our guide to step deck trailer transport, where the trailer is matched precisely to the load type.

This breakdown clarifies the key day-to-day differences.

Operational Breakdown: Lowboy vs. RGN Trailer

Here's a direct comparison of the key operational factors that distinguish a standard fixed-neck lowboy from a Removable Gooseneck trailer.

| Operational Factor | Standard Lowboy Trailer | Removable Gooseneck (RGN) Trailer |

|---|---|---|

| Loading Method | Requires external cranes, winches, or steep rear ramps. | Self-loading via a detachable neck that forms a drive-on ramp. |

| Loading Speed | Slower; dependent on availability and speed of support equipment. | Fast; equipment can be driven on and off in minutes. |

| On-Site Safety | Higher risk due to steep ramps and overhead crane operations. | Higher safety profile with ground-level, low-angle loading. |

| Equipment Needs | Requires additional machinery (cranes, etc.) for many loads. | Largely self-sufficient for loading self-propelled equipment. |

| Best Use Case | Crane-loaded static cargo and high-clearance vehicles. | Low-clearance, self-propelled machinery like pavers and excavators. |

Ultimately, the choice is determined by the nature of your cargo. An RGN streamlines the process for drivable equipment, while a lowboy remains the workhorse for static, crane-loaded freight.

Matching the Trailer to Your Equipment

When choosing between a lowboy and an RGN, the single most important factor is the equipment being hauled. The cargo's specific characteristics—its mobility, ground clearance, and dimensions—will almost always dictate the correct trailer.

Making the right choice is about ensuring the safest and most efficient transport method. The wrong trailer can lead to significant problems, including project delays, unexpected costs for support equipment, and hazardous loading conditions. A clear, practical decision-making process is crucial.

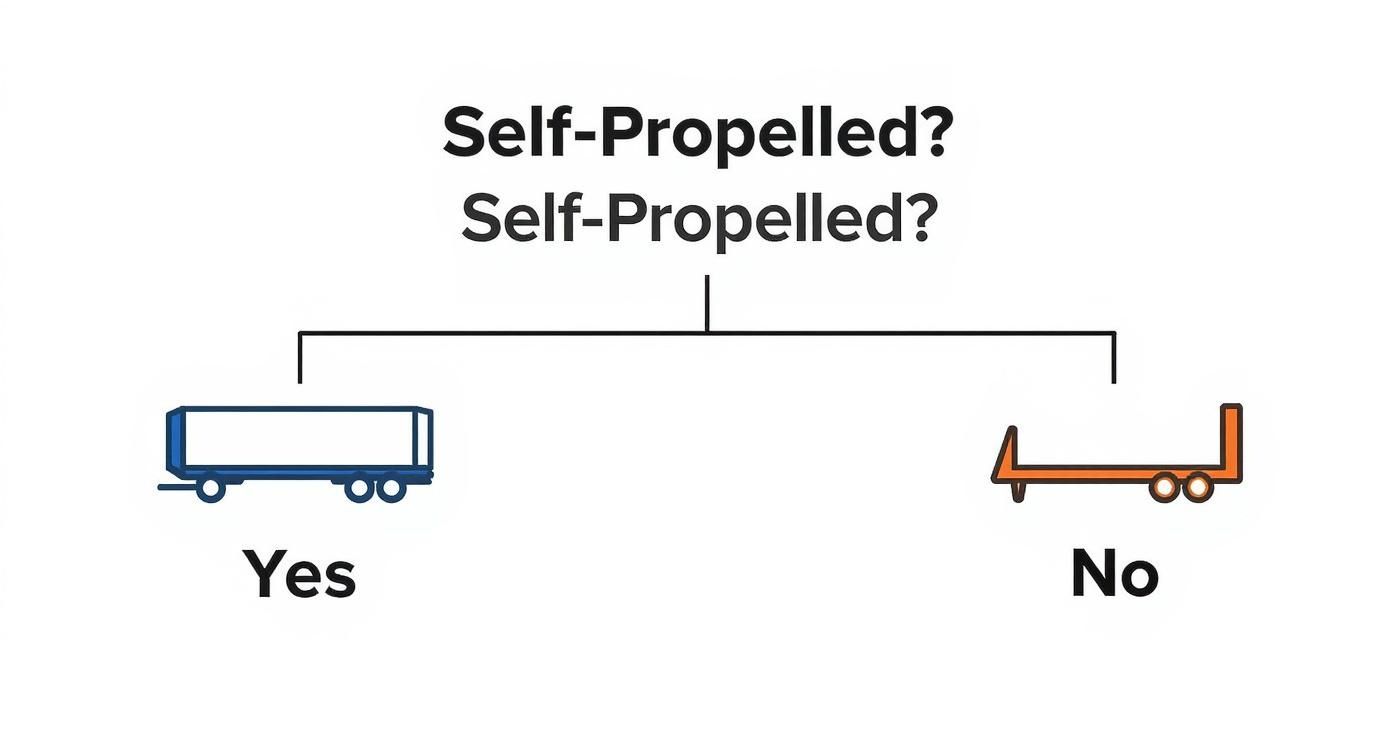

This simple decision tree illustrates the first question you should always ask.

As shown, whether the machine can move under its own power is the first critical consideration.

When an RGN Is the Only Choice

For certain types of heavy machinery, a Removable Gooseneck (RGN) trailer is the only viable option. This is particularly true for equipment that must be driven onto the trailer but has extremely low ground clearance, such as asphalt pavers, road milling equipment, or large agricultural combines.

These machines cannot safely navigate the steep incline of a fixed-neck lowboy’s rear ramps; attempting to do so would almost certainly result in damage to the undercarriage. Because an RGN’s deck can be lowered completely to the ground, it creates a gentle, seamless ramp, making it the safest and only practical choice.

Actionable Insight: If your equipment is self-propelled but has minimal ground clearance, an RGN is not just the best choice—it's the only choice. The low loading angle protects your asset and ensures a smooth, efficient process.

Scenarios Favoring a Fixed-Neck Lowboy

Conversely, a standard fixed-neck lowboy is often the more intelligent and economical selection for other cargo types. Its simpler design, wider availability, and lower operating costs make it a go-to for many transport jobs.

A fixed-neck lowboy is the ideal choice in several common transport scenarios:

- Static Industrial Components: If you're moving cargo that requires a crane for loading—such as a large generator, prefabricated steel beams, or a heavy-duty tank—the RGN’s detachable neck provides no functional benefit.

- High-Clearance Equipment: Many construction vehicles, including certain bulldozer models and large excavators, have sufficient ground clearance to easily manage the rear ramps of a lowboy. Our guide on excavator transport provides more specifics.

- Budget-Sensitive Projects: When loading methods are flexible and the cargo can handle either ramps or a crane, the lower cost of a standard lowboy makes it the clear winner for optimizing your project's budget.

By carefully evaluating your equipment's mobility and ground clearance, you can confidently select the trailer that delivers the best combination of safety, efficiency, and cost-effectiveness.

Breaking Down the Costs and Finding a Trailer

Choosing the right trailer is a financial decision. When weighing a lowboy against an RGN, you must consider the total cost of ownership, operational expenses, and trailer availability.

From the outset, an RGN has a higher acquisition cost, whether buying or renting. This is due to the complex hydraulic system required for the detachable gooseneck. More moving parts—pumps, seals, and hydraulic lines—translate to higher potential maintenance costs over the trailer's lifespan compared to a simple fixed-neck lowboy.

However, the analysis doesn't end with the initial investment. The RGN can deliver significant operational savings, especially for businesses frequently moving self-propelled equipment.

The Real Return on Your Investment

To determine which trailer offers a better return, a cost-benefit analysis is necessary. The RGN's higher fixed costs must be weighed against its potential to lower variable costs on the job.

With an RGN, you eliminate the need to hire a crane and operator, which can save hundreds or even thousands of dollars on a single move. Furthermore, you reduce labor costs by minimizing crew downtime waiting for a lift. Loading and unloading are significantly faster, allowing for more hauls per day or week.

The Bottom Line: The decision comes down to a trade-off. Compare the RGN's higher fixed costs (purchase/rental and maintenance) against its lower variable costs (no crane rentals, reduced labor time). If your operations involve frequent transport of pavers, excavators, or dozers, the RGN's efficiency will likely provide a strong return on investment.

For one-off moves or static cargo, the lowboy’s lower cost profile almost always makes it the more prudent financial choice.

Good Luck Finding One: Availability and Lead Times

Practicality often dictates choices, and trailer availability can be a decisive factor. Standard fixed-neck lowboys are the workhorses of the heavy haul industry. They are widely available, making them easy to source on short notice and keeping rental rates competitive.

RGNs are specialized equipment. Locating one, particularly a multi-axle configuration for an oversized load, can be challenging. You may need to schedule further in advance or pay a premium to a broker. This scarcity can disrupt timelines for time-sensitive projects.

Keep these logistical points in mind when planning your transport:

- Timeline: If you need a trailer immediately, a standard lowboy is your most reliable option.

- Location: RGNs may be less common in rural areas, potentially incurring extra costs to bring one to your location.

- Specifications: The more specialized the RGN (e.g., number of axles), the longer the lead time for sourcing it.

Ultimately, choosing between a lowboy and an RGN requires balancing efficiency and practicality. The RGN is a highly effective tool for specific applications, but the lowboy remains the affordable, accessible, and reliable choice for a wide range of transport jobs.

Your Top Questions About Lowboy and RGN Trailers, Answered

When planning heavy haul transport, precise details are critical. Selecting the right trailer is crucial for success, and it's common to have questions. Here are clear answers to the most frequent inquiries about lowboys and RGNs.

What's the Real Advantage of an RGN?

The primary advantage of a Removable Gooseneck (RGN) trailer lies in its loading method.

The RGN's gooseneck detaches, allowing the front of the trailer deck to rest directly on the ground. This creates a gentle, full-width ramp, which is a major benefit for self-propelled equipment, especially low-clearance machines like asphalt pavers. This drive-on capability makes the entire process safer, faster, and more efficient by eliminating the need for external cranes or steep ramps.

When is a Standard Lowboy the Better Call?

While the RGN is an excellent piece of engineering, a standard fixed-neck lowboy is often the more practical and cost-effective choice. Its simpler design means it is more widely available and less expensive.

A standard lowboy is the superior option in these situations:

- When Using a Crane is Necessary: For static cargo like industrial generators, pipes, or building modules that require crane loading, the RGN’s drive-on feature offers no advantage.

- For High-Clearance Machines: Equipment such as bulldozers, wheel loaders, and many excavators can safely navigate the rear ramps of a standard lowboy, making the extra cost of an RGN unnecessary.

- When Budget is the Priority: If your cargo can be loaded without an RGN's specialized features, the lower rental fees and simpler logistics of a fixed-neck lowboy make it the clear choice for cost-conscious projects.

The Bottom Line: The decision is about what your job requires. Don't pay for RGN features if your equipment and loading site don't demand them.

Are RGNs More Expensive to Maintain?

Yes, RGNs are definitively more expensive to maintain. The hydraulic and mechanical systems that enable the gooseneck to detach are complex.

These systems include more moving parts, such as hydraulic cylinders, seals, and fluid lines, all of which require regular inspection, service, and eventual replacement. This complexity means repairs are more specialized and costly compared to the simple, welded frame of a fixed-neck lowboy.

What Does RGN Actually Stand For?

In the transport industry, RGN stands for Removable Gooseneck.

The "gooseneck" is the arched section of the trailer that connects to the semi-truck's fifth wheel. "Removable" describes its key feature: the ability to detach, allowing machinery to be driven directly onto the deck. The name itself perfectly summarizes its primary function.

When you need the right trailer for your project, leave the logistics to the pros. We Will Transport It has spent over a decade matching heavy equipment with the perfect transport solution, getting valuable assets delivered safely and on schedule. Get a no-nonsense quote for your next haul at https://www.wewilltransportit.com.