A successful 5th wheel hook up is a precise process, critical for both personal travel and professional transport. It begins with a thorough safety inspection—a non-negotiable routine that identifies potential issues before they become major problems on the road. Mastering this process ensures a safe, secure connection every time, whether you're heading to a campsite or preparing a rig for a transport company.

Your Pre-Hook Up Safety Inspection

This pre-check is the foundation of a safe tow. A few minutes spent here will save you from costly damage and significant delays. The goal is to verify that both the truck and trailer are ready to be safely connected. This crucial coupling system is so central to transport that the global market for fifth wheel couplings was valued at USD 635 million in 2023, underscoring its importance in the logistics and recreational industries.

Pre-Hook Up Inspection Checklist

Before backing up, use this checklist to establish a consistent, safe routine. This systematic approach is essential for both RV owners and transport professionals to prevent common, costly mistakes.

| Component Check | Actionable Insight | Why It's Critical for Transport |

|---|---|---|

| Trailer Wheels | Chock wheels securely on the downhill side. | Prevents trailer movement during hookup, ensuring driver safety and preventing damage. |

| Truck Tailgate | Ensure the tailgate is completely lowered. | A raised tailgate will cause immediate, expensive damage to the trailer's front cap upon contact. |

| Truck Bed | Clear all tools, debris, or other items. | Obstructions can damage the hitch mechanism or prevent the kingpin from seating correctly. |

| Trailer Kingpin | Inspect for damage and ensure it's lightly greased. | A clean, properly lubricated kingpin ensures a smooth connection and prevents wear on the locking jaws. |

| Hitch Jaws | Confirm jaws are fully open, clean, and move freely. | Sticky or damaged jaws are a primary cause of failed connections and unsafe tows. |

| Trailer Height | Adjust so the kingpin plate is slightly below the hitch plate. | This allows the truck to slide under, preventing a "high hook"—one of the most dangerous connection errors. |

This checklist covers the absolute essentials for a secure mechanical connection, forming the basis of a professional and safe hook up procedure.

Initial Trailer and Truck Prep

First, secure the trailer by chocking the wheels. Use heavy-duty chocks on the downhill side to eliminate any chance of the trailer rolling. This step is non-negotiable for safety.

Next, lower the truck's tailgate. This simple action prevents one of the most common and costly mistakes in the 5th wheel world. While at the rear of the truck, inspect the bed for any loose items—tools, wood, or other gear—that could interfere with the hitch operation.

Pro Tip: Develop a fixed routine and execute it in the same order every time: Chocks, Tailgate, Clear Bed. This builds muscle memory and dramatically reduces the chance of skipping a critical step, a best practice in the transport industry.

A proper hookup is just one element of overall vehicle readiness. To ensure your rig is fully prepared for the road, consult an ultimate trailer maintenance checklist for a comprehensive overview of essential maintenance tasks.

Inspecting the Key Components

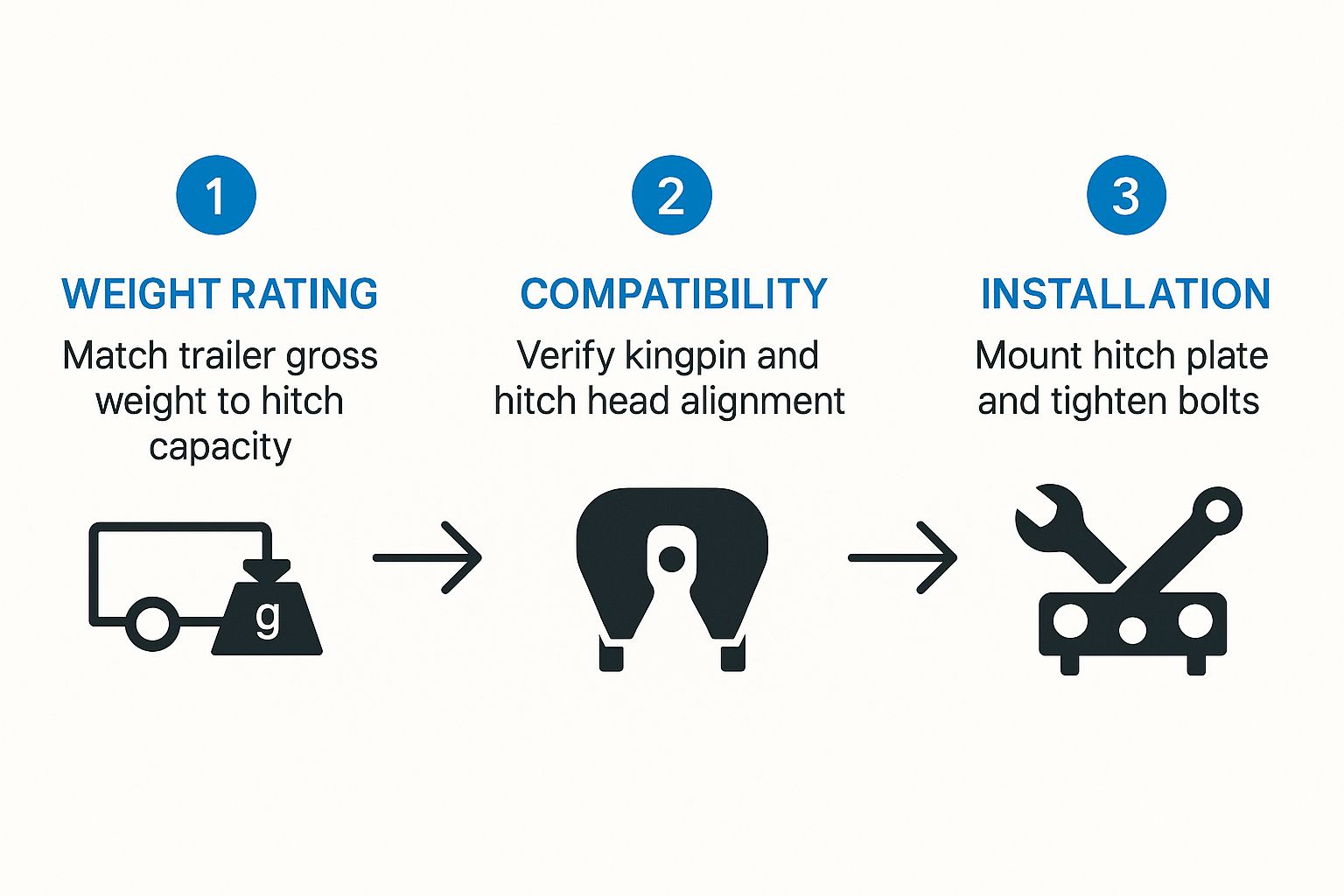

Now, perform a detailed inspection of the two most critical connection parts: the kingpin and the hitch.

-

The Kingpin: Visually inspect the kingpin and its surrounding plate. Look for cracks, deep gouges, or excessive wear. The plate should be clean with a light film of grease to facilitate a smooth coupling.

-

The Hitch Jaws: Check that the locking jaws in the truck's hitch are fully open. Inspect the mechanism for rust, dirt, or damage that could impede its movement. A locking mechanism that doesn't move freely cannot be trusted.

Finally, adjust the trailer's height using the landing gear. The kingpin plate must be set just slightly lower than the hitch plate. This alignment is crucial. It ensures the truck's hitch slides underneath the trailer plate, guiding the kingpin directly into the locking jaws. Setting the trailer too high creates the risk of a "high hook," a severe safety failure where the kingpin fails to lock into the jaws.

Properly preparing your trailer is a key part of the transport process. For detailed steps, see our guide on preparing an Alpine fifth wheel for shipping.

Aligning Your Truck and Trailer Like a Pro

A precise 5th wheel hook up is a repeatable skill, not a matter of luck. The key to a smooth, stress-free alignment is starting with a straight line and using methodical adjustments.

Before reversing, align the truck as straight as possible with the trailer, even from a distance. A straight starting position simplifies the entire backing process. Approaching at a sharp angle makes minor corrections difficult and increases the risk of misalignment.

Mastering Your Mirrors and Visual Cues

Your side mirrors are your primary tools for alignment. Avoid the temptation to look over your shoulder out the back window, as this distorts your perception of angles and distance. Instead, monitor both side mirrors, keeping an equal amount of the trailer visible in each. This confirms you are maintaining a straight path.

As you get closer, your focus should be on guiding the trailer's kingpin directly to the center of the hitch head in your truck bed.

- Make Small Corrections: Large, sudden steering inputs are your enemy. Make small, deliberate turns and observe their effect in the mirrors. A tiny adjustment at the steering wheel creates a significant change at the rear of the truck.

- Use the "Bottom-of-the-Wheel" Technique: Place your hand at the bottom (6 o'clock position) of the steering wheel. Whichever direction you move your hand is the direction the rear of the trailer will move. This simple trick removes the mental gymnastics of reverse steering.

Working with a Spotter

While a solo hookup is possible, using a spotter is a best practice for safety and efficiency, especially in professional transport. Effective communication is critical. Before you start, agree on a clear set of hand signals for "left," "right," "straight back," and the most important command: "STOP."

A professional connection process starts with methodical safety checks long before the truck is put in reverse.

A spotter should be positioned where the driver can clearly see them in the driver's-side mirror. Their only job is to watch the alignment of the kingpin and hitch, providing clear guidance.

A spotter's most vital role is to call a loud, clear "STOP" when the kingpin is positioned directly over the hitch, just before making contact. This prevents impact damage and ensures perfect positioning.

Never hesitate to pull forward and restart if the alignment is off, especially on uneven ground. Forcing a misaligned connection can damage the kingpin or hitch jaws, leading to costly repairs and an unsafe tow. Patience and precision are the keys to mastering this skill.

Securing the Kingpin Connection

With the truck and trailer aligned, the next step in the 5th wheel hook up is the physical connection. This must be a slow and controlled maneuver.

Allow the truck to idle backward slowly. The goal is a smooth slide, not a hard impact. As the truck's hitch plate slides under the trailer's kingpin plate, it will guide the kingpin into the V-notch of the hitch.

Listen carefully for a distinct, solid 'CLICK'. This sound indicates that the locking bar or jaws have closed securely around the kingpin. This is your initial confirmation of a successful latch, but it must be followed by a physical verification.

Confirming a Solid Lock

An audible click is not enough. You must perform a visual inspection. Exit the truck and look directly at the hitch head.

Confirm that the jaws are fully closed around the base of the kingpin and that the release handle has moved completely into its locked position. If there is any visible gap between the jaws and the kingpin, the connection is not secure.

The 5th wheel system, adopted from the commercial trucking industry, is designed for stability by transferring a significant portion of the trailer's weight directly over the truck's rear axle. This makes it inherently more stable than a bumper-pull trailer, but only if the connection is perfect.

The Tug Test: Your Final Confirmation

This step is mandatory. With the trailer wheels still chocked, return to the cab. Manually apply the trailer brakes using the in-cab controller, then place the truck in drive. Gently press the accelerator. The truck should strain against the trailer's brakes without any movement at the hitch. This test proves the mechanical lock is secure before you put it under load on the highway.

Connecting Power and Safety Systems

With the mechanical connection confirmed, connect the electrical and safety lines. The coiled power cord, or "umbilical," links the truck's systems to the trailer's lights and electric brakes.

- Umbilical Cord: Plug the cord firmly into the truck bed receptacle. Ensure there is enough slack for sharp turns but not so much that it can drag or get caught in the hitch mechanism.

- Breakaway Cable: This is a critical safety device. Clip the cable to a dedicated anchor point on the truck's frame or bed—never to the hitch itself. In the event of a catastrophic disconnection, this cable pulls a pin that activates the trailer's brakes, bringing it to a stop.

Securing these systems is just as important as the mechanical lock. It’s a standard operating procedure for all professional haulers and RV owners alike.

Your Final Road-Ready Safety Checks

The connection is made and has passed the tug test. Before pulling away, conduct a final walk-around. This is the last opportunity to catch a minor oversight before it becomes a major safety issue on the highway.

https://www.youtube.com/embed/y1j76hUeR88

First, fully retract the trailer's landing gear. Raise the legs completely until they are well clear of the ground to prevent them from catching on curbs, speed bumps, or uneven terrain. Damaged landing gear can derail a trip or a transport job.

Lights, Cables, and Controller Checks

Next, verify that all electrical systems are communicating. This is best done with a partner, but a solo driver can use reflections or a phone camera to check the lights.

- Running Lights: Turn on the truck's headlights to confirm all trailer marker and tail lights illuminate.

- Brake Lights: Press the brake pedal and verify that all brake lights on the trailer are bright and functional.

- Turn Signals: Test the left and right signals individually.

- Emergency Flashers: Activate the four-way flashers as a final check to see all signal lights working together.

After confirming the lights, double-check the umbilical and breakaway cables. Adjust the slack as needed to prevent dragging or snagging during turns.

Finally, check the trailer brake controller inside the truck's cab. Ensure it shows a solid connection and displays no error messages like "Trailer Disconnected."

Your final walk-around is a professional habit that ensures safety and peace of mind. Identifying a disconnected cable or a burnt-out bulb in a stationary position is a simple fix; discovering it at highway speeds is a critical safety failure.

With the fifth-wheel trailer market reaching USD 15.8 billion in 2023, more rigs are on the road than ever. Mastering these fundamental safety procedures is crucial for every operator. For more insights on moving RVs, review our tips and tricks for shipping an RV or trailer.

Troubleshooting Common Hook Up Problems

Even experienced drivers encounter problems during a 5th wheel hook up. Most issues are common and have straightforward solutions. Knowing how to diagnose and resolve these snags quickly is a key skill for any operator.

The most common issue is height misalignment. If the trailer is too low, the kingpin will hit the front of the hitch. If it's too high, you risk the most dangerous error: a high hook.

The Dangers of a High Hook

A "high hook" occurs when the trailer's kingpin rests on top of the hitch plate instead of locking within the jaws. The connection may feel secure, but it is not. The trailer can disconnect from the truck on the first significant bump or turn, leading to a catastrophic accident.

If you suspect a high hook, stop immediately. Do not attempt to "settle" it into place by pulling forward, as this will damage the hitch, kingpin, and truck bed.

How to Safely Fix a High Hook

If a high hook occurs, lower the trailer's landing gear to take the full weight off the truck, lifting the kingpin clear of the hitch. Pull the truck forward. Then, correctly readjust the trailer's height and restart the alignment process from the beginning.

When the Hitch Won't Lock

Sometimes, the alignment is perfect, but the locking mechanism fails to engage. You don't hear the characteristic clunk of the jaws closing.

Troubleshoot with these steps:

- Is it Greased? Insufficient grease on the hitch plate and kingpin creates excessive friction that can prevent the kingpin from sliding fully into place. Applying a quality 5th wheel grease often solves the problem.

- Check the Release Handle: Confirm the release handle was moved to the fully open position before you started backing up. A partially opened handle will not allow the jaws to accept the kingpin.

- Look for Debris: A small rock, dirt, or hardened grease can physically obstruct the locking mechanism. A quick visual inspection and cleaning can resolve the issue.

Knowing how to troubleshoot these common problems transforms a frustrating delay into a quick adjustment. A successful 5th wheel hook up relies on a patient, methodical approach, especially when things don't go perfectly on the first try.

Answering Your 5th Wheel Hook Up Questions

Even with a detailed guide, practical questions always arise. Here are actionable answers to the most common queries, designed to build your confidence for a perfect hook up.

How Do I Know My 5th Wheel Is Actually Locked?

Never guess. Use this three-step verification process: Listen, Look, and Pull.

- Listen: As the kingpin seats, you must hear a loud, sharp ‘CLICK’. This is the sound of the locking jaws engaging. No click means no connection.

- Look: Get out of the truck and perform a direct visual inspection. The release handle must be in the fully locked position. The locking jaws must be completely wrapped around the base of the kingpin. There should be no gap between the kingpin flange and the hitch plate.

- Pull: Perform the tug test. With the trailer wheels securely chocked, apply the trailer brakes and put the truck in drive. Gently pull forward. The truck should strain against the trailer, confirming the mechanical lock is solid.

What’s a “High Hook” and How Do I Avoid It?

A "high hook" is a critical failure where the kingpin rests on top of the hitch instead of locking inside it. It looks connected but will detach on the road.

To avoid it, always set the trailer height correctly before backing up. The trailer's kingpin plate must be slightly lower than the truck's hitch plate. This forces the truck to lift the trailer slightly as it slides underneath, ensuring the kingpin aligns perfectly with the locking jaws.

If you suspect a high hook, DO NOT attempt to fix it by moving the truck. Stop, lower the landing gear to support the trailer, pull the truck clear, and restart the entire hook-up process.

Is It Safe to Hook Up on Uneven Ground?

While not ideal, hooking up on uneven ground is often necessary. It requires extra vigilance.

- Chock Your Wheels: This is non-negotiable. Always chock the downhill side of the trailer wheels to prevent rolling.

- Mind the Angle: Severe side-to-side angles between the truck and trailer can cause the kingpin and jaws to bind, preventing a secure lock.

Do your best to align the truck and trailer as squarely as possible. If the slope is too extreme, the safest action is to reposition the truck or trailer to a flatter area. Forcing a connection at a severe angle risks damaging your equipment.

When it comes to moving your 5th wheel or any vehicle without the hassle, having a pro on your side is key. For reliable and stress-free shipping, the experts at We Will Transport It have you covered. Get your free, no-obligation transport quote today!