Ever had that sinking feeling when a critical piece of equipment isn't where it's supposed to be? Or when a project grinds to a halt because a machine is down for unexpected maintenance? A modern construction equipment tracking system is designed to eliminate these headaches. It gives you a live, bird's-eye view of every single asset, whether it's digging on-site, sitting in the yard, or on a low-boy heading to the next job.

Think of it as the central command for your entire fleet.

Why Equipment Tracking Is Your New Competitive Edge

Trying to manage millions of dollars in heavy equipment without real-time data is like running a job site blindfolded. It's chaotic, inefficient, and incredibly expensive. You're left guessing where your assets are, if they're even being used, and when they'll finally show up at the next location. This constant uncertainty creates friction that leads directly to project delays and bloated budgets.

The root of the problem is simple: you can't manage what you can't see. Without a proper tracking system, every decision about moving and allocating equipment is a shot in the dark, based on old information or gut feelings. Those "best guesses" often turn into costly mistakes that hit your bottom line hard.

Transforming Transport Logistics from Guesswork to Precision

One of the biggest daily headaches for any construction manager is just getting the right machine to the right place at the right time. It's a logistical puzzle that can make or break a project schedule. Equipment tracking systems solve this by giving you precise, up-to-the-minute location data for every asset.

This visibility completely changes how you plan transport:

- Actionable Insight: Instantly see which machine is closest to the next job, slashing unnecessary travel time and fuel costs. Don't guess; dispatch the most logical asset.

- Accurate Scheduling: Give clients and foremen reliable ETAs for equipment in transit, so crews aren't standing around waiting for an excavator to arrive.

- Better Route Planning: Monitor transport routes in real-time to spot and correct inefficiencies, ensuring drivers are taking the best path and avoiding delays.

- Proof of Delivery: Automatically log arrival and departure times from geofenced job sites, creating a digital record that eliminates disputes.

You move from being reactive to proactive. Instead of just hoping for the best, you can move assets with total confidence, knowing they’ll be put to work, not stuck in traffic.

An untracked fleet runs on assumptions. A tracked fleet runs on facts. This one change turns your equipment from a constant logistical headache into a powerful competitive advantage.

Gaining a Financial and Operational Advantage

Putting tracking systems on your fleet isn't just about cool tech; it's a smart business move with a clear ROI. The global market for construction equipment tracking was valued at around US$1.8 billion in 2024 and is expected to climb to US$3.0 billion by 2030. This explosive growth shows just how seriously the industry is taking theft prevention, asset utilization, and overall efficiency. You can learn more about the market growth of equipment tracking systems.

When you implement a solid tracking solution, you're getting far more than just dots on a map. You're unlocking a treasure trove of data that gives you real, actionable insights. It’s how you turn expensive, idle iron into secure, productive, and profitable assets.

Unlock Your Fleet's Potential with Core Features

A modern construction equipment tracking system isn't just a dot on a map. It’s a complete toolkit designed to tackle the exact headaches that keep project managers up at night. Each feature is a direct answer to a common challenge, turning guesswork into solid information and making your entire transport operation more efficient and secure.

This technology, known as telematics, combines GPS with smart data reporting. It’s not a niche gadget anymore—it's becoming standard practice. The construction telematics market was valued at around US$1.48 billion in 2024 and is expected to balloon to nearly US$3.82 billion by 2032. Why? Because the benefits are real and measurable.

Let's dig into the core features that drive these results, especially when it comes to moving your equipment from one site to the next.

Your Digital Fortress: GPS and Geofencing

The foundation of any tracking system is, of course, real-time GPS location. Knowing exactly where every bulldozer, crane, and generator is at all times is ground zero. This basic visibility is critical for everything from dispatching the closest asset to a new job to simply confirming it arrived safely.

But GPS really shows its power when you add geofencing to the mix. Think of a geofence as a digital fence you can draw around any area on a map—your equipment yard, a specific job site, or even a service depot.

When a piece of equipment crosses that line, the system sends an instant alert. This provides valuable, actionable insights for transport:

- After-Hours Security: Get a text message the moment an excavator leaves the site at 2 a.m., giving you a fighting chance against theft.

- Transport Deviation: Set a geofence along a planned transport route. If the truck hauling your paver goes off-course, you'll know right away and can intervene.

- Arrival Confirmation: Automatically notify the site foreman that a new dozer has arrived, so they can get the unloading crew ready without a dozen phone calls.

- Yard Management: Get alerts when equipment returns to the yard, streamlining check-in and preparing it for the next dispatch.

This combination of GPS and geofencing transforms your map from a static picture into an active security and logistics command center. For a closer look at the tech behind this, it's worth understanding how UAV GPS tracker systems achieve similar pinpoint accuracy.

The table below breaks down how these core features directly translate into tangible benefits for both your logistics team and on-site crews.

Key Features and Their Operational Impact

| Core Feature | Primary Function | Impact on Transport & Logistics | Impact on Site Operations |

|---|---|---|---|

| GPS Tracking | Pinpoints asset location in real time. | Optimizes dispatching, confirms delivery times, and provides accurate ETAs. | Quickly locates equipment on large sites, improving resource allocation. |

| Geofencing | Creates virtual boundaries and triggers alerts. | Secures assets during transit, prevents unauthorized route deviations, and automates arrival/departure logs. | Prevents unauthorized use after hours and ensures equipment stays within designated work zones. |

| Engine Hour Tracking | Logs actual machine runtime automatically. | Ensures equipment is serviced before long-haul transport, preventing en-route breakdowns. | Schedules proactive maintenance based on usage, maximizing uptime and reducing project delays. |

| Fuel & Behavior Monitoring | Tracks fuel consumption and operator habits. | Reduces fuel theft during transport and identifies inefficient driving that causes wear and tear. | Catches fuel siphoning on-site and identifies operators who need coaching on efficient machine use. |

As you can see, each feature serves a dual purpose, streamlining the journey to the job site and optimizing performance once it's there.

Proactive Maintenance with Engine Hour Tracking

Waiting for a machine to break down is one of the costliest, most disruptive events on any project. Engine hour tracking flips the script, moving you from a reactive "fix-it-when-it-breaks" model to a proactive, predictive one. This is especially crucial for equipment that’s constantly on the move.

Instead of relying on messy paper logs or simple calendar reminders, the system automatically clocks the actual runtime of every single engine. This data provides an actionable insight for your transport strategy: before dispatching a machine for a long-haul job, a quick check of its service record ensures it's not due for maintenance. This simple step can prevent a costly breakdown hundreds of miles from a service depot.

With automated engine hour tracking, maintenance becomes a predictable, data-driven process, not an emergency. This simple feature extends asset lifespan, maximizes uptime, and prevents costly transport delays caused by unexpected breakdowns.

This means you can set alerts tied directly to the manufacturer's recommended service intervals. When a grader is nearing its next oil change or a hydraulic system check, your maintenance team gets an automatic heads-up. You can schedule the work during planned downtime, not in the middle of a critical transport leg.

Eliminating Waste with Fuel and Behavior Monitoring

Fuel and wear-and-tear from rough handling are two of the biggest drains on your budget, especially during transport. A good tracking system gives you the data to plug those leaks.

Fuel monitoring can spot sudden drops in the tank, a tell-tale sign of theft or a leak. More importantly, it cross-references fuel consumption with engine hours, helping you flag machines that are guzzling fuel due to excessive idling or a hidden mechanical issue.

At the same time, driver behavior analytics keep an eye on things like harsh braking, sudden acceleration, and speeding. This information is pure gold for coaching your transport drivers. These habits don't just waste fuel; they put incredible strain on both the truck and the expensive equipment it's hauling. By promoting smoother driving, you directly cut maintenance costs and make your transport operations safer for everyone.

The Real-World Benefits of Tracking Your Assets

It's one thing to read a list of features for a construction equipment tracking system, but it's something else entirely to see how those features actually make a difference on the job site and on your balance sheet. The real value isn’t just knowing where a machine is—it's what that knowledge empowers you to do.

When you can see your entire fleet in real-time, the benefits start to stack up. You’re not just preventing theft or optimizing a delivery route; you’re making fundamental improvements to how your entire operation runs, from the ground up.

Drastically Reduce Theft and Accelerate Recovery

Let’s face it: construction sites are a magnet for thieves, and equipment theft can cost a company millions in a single year. A good tracking system is your first line of defense, acting as both a powerful deterrent and an incredible recovery tool. With geofencing, you get an instant alert the moment a dozer or an excavator moves outside its designated zone after hours.

That immediate notification gives you a massive head start. You can contact law enforcement right away and give them live, actionable location data to track and recover your stolen property, often within hours. An actionable insight for transport is setting up specific geofences around storage yards and along transit corridors to immediately flag any unauthorized deviation.

The ability to provide a real-time "breadcrumb trail" of a stolen asset's location can be the difference between a quick recovery and a total loss. This capability alone often justifies the entire investment in a tracking system.

Of course, technology works best when it's part of a complete strategy. Pairing digital tracking with robust physical security for site assets gives you multiple layers of protection against both theft and unauthorized use.

Optimize Transport and Slash Fuel Costs

Fuel is a massive, unpredictable expense, especially when you’re hauling heavy machinery from one project to the next. Tracking systems give you the hard data you need to clamp down on two of the biggest money pits: inefficient routes and excessive engine idling.

Here's an actionable insight: use your system's historical data to create a "best route" library for common transport runs between your yard and frequent job sites. By looking at historical travel data, you can instantly spot where drivers are taking the long way around. Correcting those suboptimal routes cuts down on mileage, which means less fuel burned and less wear and tear on your transport vehicles. For bigger moves, knowing the ins and outs of specialized hauling is crucial, and working with experts in construction equipment transport can help you dial in that efficiency even further.

Beyond routing, tracking systems give you a perfect record of engine run time. You can finally see exactly how much time your machines spend idling—and wasting fuel. An excavator can easily burn a gallon of diesel per hour just sitting there, which adds up to thousands of dollars over the course of a project. With idle-time alerts, you can coach operators on best practices and build a fuel-saving culture across all your sites.

Shift to Proactive, Data-Driven Maintenance

Nothing kills a project timeline and budget faster than an unexpected breakdown. Tracking systems help you get ahead of mechanical failures by shifting your maintenance schedule from reactive guesswork to proactive, data-driven planning. The system automatically and accurately logs engine hours for every single piece of equipment.

Forget relying on messy paper logs or arbitrary calendar reminders. Now you can service your machinery based on its actual usage, exactly when the manufacturer recommends it. For transport, this means you can build a mandatory pre-transport maintenance check into your workflow, triggered by system data, ensuring no machine leaves the yard with a pending service alert.

This approach lets you:

- Prevent Breakdowns: Catch and fix small problems before they turn into catastrophic failures.

- Maximize Uptime: Schedule service during planned downtime, not in the middle of a critical concrete pour.

- Extend Asset Lifespan: Keep your equipment in peak condition for longer with consistent, timely maintenance.

This smarter approach ensures your fleet is always reliable and ready to roll, whether it's heading to a new job or getting loaded for transport.

Inform Smarter Bids and Future Planning

Ultimately, all the data your tracking system gathers becomes a powerful strategic tool. By analyzing utilization reports, you get a crystal-clear picture of which machines get used the most, where they're working, and for how long.

This historical data is gold when you're bidding on new jobs. You can estimate your equipment needs with far greater accuracy, helping you put together more competitive and profitable proposals. A valuable insight for transport is analyzing historical location data to accurately calculate mobilization and demobilization costs for bids, replacing guesswork with hard numbers. It also helps you make smarter decisions about your fleet—should you buy that new loader, rent one for the season, or just move an underused one from another site? With real data, you can turn those operational insights into a true competitive advantage.

How to Choose the Right Tracking System

Picking the right construction equipment tracking system can feel like a huge decision, but you can take the guesswork out of it by following a clear process. The goal isn't just to track your assets; it's to find a solution that genuinely solves your day-to-day operational and transport headaches. It all starts with taking an honest look at your own fleet and how you work.

This isn't about finding the system with the longest list of features. It's about finding the one with the right features for your business. A small contractor with ten pieces of equipment has completely different needs than a large company managing hundreds of assets across multiple states. Getting a clear picture of your starting point is the single most important step.

Assess Your Fleet and Operational Needs

Before you even think about looking at a vendor's website, you need to map out your own requirements.

Start with the basics. How many pieces of equipment do you need to track? What kind of machines are they—heavy iron like excavators, support equipment like generators, or the on-road vehicles you use for transport?

Next, dig into your biggest pain points.

- Is theft your main worry? If so, real-time alerts and geofencing are absolute must-haves.

- Are transport logistics a constant struggle? Then you'll need a system with solid route optimization and accurate ETA reporting. Look for features that let you share a live tracking link with site foremen.

- Is unexpected downtime blowing up your budget? Prioritize systems with automated engine hour tracking and predictive maintenance alerts.

This initial self-assessment gives you a scorecard to measure every potential system against. Without it, you’re just setting yourself up to be wowed by a flashy demo that doesn’t actually fix your core problems.

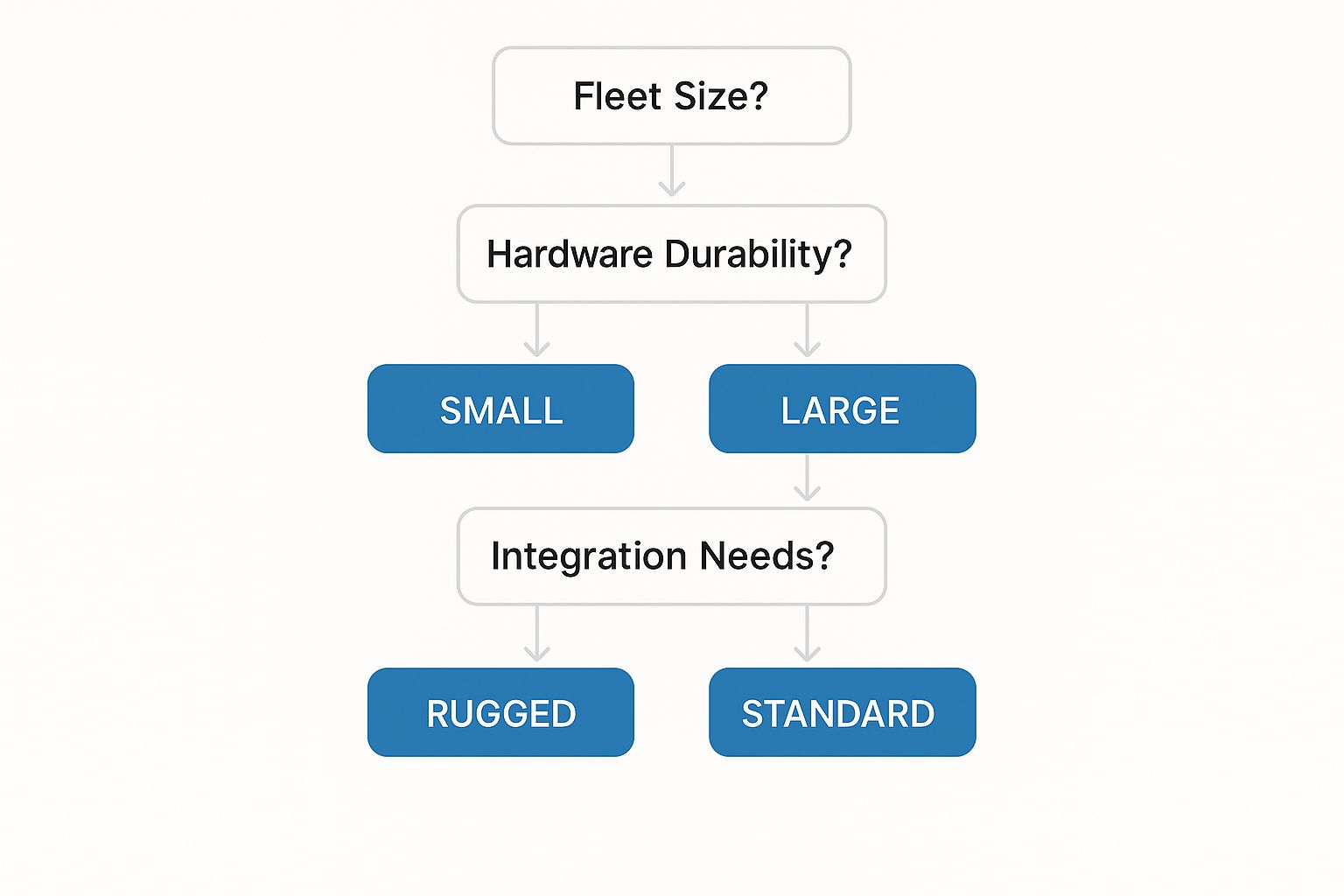

This decision tree can help you visualize the key forks in the road during the selection process, guiding you from fleet size to your specific technology needs.

As you can see, there’s no single "best" system. The ideal choice really depends on the scale of your operation, the durability required for your job sites, and how deeply the technology needs to plug into the software you already use.

Evaluate Hardware, Software, and Integration

Once you have your needs clearly defined, you can start looking at vendors. It helps to focus on three critical pillars: the physical hardware, the software platform, and how well it integrates with the tools you already have.

The hardware has to be tough enough to survive a construction site. Period. Look for devices with high IP ratings for dust and water resistance, long battery life, and a rugged case that can handle constant vibrations and impacts. For specialized machinery, like that involved in transporting Komatsu equipment, you have to make sure the trackers can be installed without interfering with the machine’s complex systems.

The software is where you and your team will spend most of your time. Is the interface intuitive? Is it easy for everyone to learn? Does the mobile app give managers in the field the full functionality they need? A powerful system is worthless if nobody uses it.

A great tracking system feels like a natural extension of your workflow, not another complicated program to learn. Prioritize a user-friendly interface and seamless integration to ensure your team actually adopts and benefits from the technology.

Finally, think about integration. A tracking system really shows its power when it starts sharing data with your other business software. Can it connect to your accounting platform for more accurate job costing? What about your project management software for smarter resource allocation? This connectivity is what turns raw location data into profitable business decisions.

To help you compare different systems, we've put together a simple checklist. Use it to keep your evaluations focused and consistent as you talk to vendors.

System Selection Checklist

| Evaluation Criteria | Key Questions to Ask | Importance Level (High/Medium/Low) |

|---|---|---|

| Hardware Durability | What is the IP rating? Can it withstand vibration, dust, and impact? What is the battery life? | High |

| Software Usability | Is the interface intuitive? Is there a fully functional mobile app? How steep is the learning curve? | High |

| Core Tracking Features | Does it offer real-time GPS, geofencing, and historical location data? | High |

| Maintenance & Health | Can it track engine hours, fault codes, and schedule maintenance alerts? | Medium/High |

| Integration Capability | Does it have an open API? Can it connect to our accounting or project management software? | Medium/High |

| Customer Support | What are the support hours? Is training included? Do they understand the construction industry? | Medium |

| Scalability | How easy is it to add more assets? Does the pricing structure support growth? | Medium |

| Total Cost | What are the upfront hardware costs, monthly fees, and any hidden installation or service charges? | High |

This checklist isn't exhaustive, but it covers the critical areas that will determine whether a system is a good fit for your business both today and in the future.

Look Beyond the Price Tag

While your budget is obviously a major factor, the initial price tag is only part of the story. You need to look at the total cost of ownership and the long-term value the system brings. The entire construction equipment fleet management software market is booming, projected to grow from around US$5.2 billion in 2025 to a massive US$21.3 billion by 2035. This trend shows a huge industry shift toward data-driven management, proving that the return on investment is there. You can read the full research on fleet management software market growth.

When you’re talking to vendors, be sure to ask these questions:

- What does your customer support and training look like? A dedicated support team that actually understands construction is invaluable.

- Is the system scalable? Can you easily add more assets as your company grows without a big price jump?

- What are all the fees? Get clear answers on installation costs, monthly subscription tiers, and any other potential charges.

Choosing the right construction equipment tracking system is a strategic investment in your company's efficiency, security, and bottom line. By focusing on your unique needs and carefully evaluating vendors on their hardware, software, and long-term value, you can find a partner that helps you streamline transport and boost profitability for years to come.

Your Step-by-Step Implementation Roadmap

Even the most powerful equipment tracking system is useless if the rollout is a mess. A rushed or poorly planned implementation can cause chaos and pushback from your team, ultimately delaying any real return on your investment.

This roadmap breaks the process down into clear, manageable steps. Following it will ensure a smooth transition, allowing you to start seeing the benefits without throwing a wrench into critical site work or transport schedules.

Phase 1: Set Clear and Measurable Goals

Before you even think about installing a tracker, you need to define what a "win" looks like for your company. Your goals can't be vague; they must be specific, measurable, and directly linked to your biggest operational headaches.

Are you bleeding money from unauthorized equipment use? Trying to tighten up your transport routes? Or just trying to get a handle on preventive maintenance?

For instance, a solid transport-focused goal would be: "Reduce unauthorized equipment moves by 90% in the first quarter by implementing after-hours geofence alerts." Or perhaps: "Improve transport efficiency by cutting average mileage per trip by 10% through route optimization analysis." Having these targets gives the whole project a purpose and a benchmark to measure your success against.

Phase 2: Run a Strategic Pilot Program

Don't try to outfit your entire fleet at once. That's a recipe for disaster. Instead, start small with a controlled pilot program.

Pick a handful of different assets to test the system on. Maybe grab a high-use excavator, a generator that’s always on the move, and one of your main transport trucks. This small-scale test lets you work out the kinks without causing major disruptions.

During the pilot, you'll want to focus on:

- Hardware Installation: Get a feel for the install process on different types of machines. Bolting a tracker onto a massive dozer is a different game than wiring one into a skid steer.

- Software Configuration: Tweak your alerts, geofences, and reports. You want them to deliver valuable transport information, such as route deviation alerts, not just a constant stream of notifications.

- Workflow Integration: See how the data actually fits into your team's day-to-day. How does it change things for dispatch, the mechanics, or the transport logistics crew?

A pilot program is your implementation dress rehearsal. It’s the perfect opportunity to identify potential challenges, gather feedback from a core group of users, and refine your processes before the main event.

Phase 3: Install Hardware and Configure the Software

Once the pilot program runs smoothly, it's time for the full rollout.

Schedule the hardware installations strategically to minimize downtime. You could tackle equipment in batches after hours or over a weekend, ensuring every machine is ready to go for its next transport. It’s a smart move to document the installation for each type of equipment, especially for the big, complex machinery involved with transporting Caterpillar equipment. This creates a handy guide for the future.

While the hardware is going in, get the software platform configured for the whole fleet. This means:

- Creating Asset Profiles: Enter the details for every piece of gear—make, model, year, and which department it belongs to.

- Setting Up Geofences: Draw virtual perimeters around all your job sites, the main yard, and any sensitive or off-limits areas.

- Establishing User Roles: Control who sees what. Foremen, mechanics, and dispatchers all need different information, so set up their access levels accordingly.

Phase 4: Train Your Team for Success

This is the most critical step. New tech is only as good as the people using it.

Your training needs to focus on the "why." Explain how this system makes everyone's job easier—less manual paperwork, fewer surprise breakdowns, and smoother transport requests.

Customize the training for different roles. Show operators how to use the system for their daily pre-start checks. Teach foremen how to pull utilization reports to get the right machine to the right place. Walk your dispatch team through using real-time location data to nail down transport routes and give customers accurate ETAs. An actionable tip is to create one-page "quick start" guides for each role, focusing on the 2-3 key tasks they'll perform in the system.

Good training, followed by ongoing support, is what turns a skeptical crew into a team of confident, empowered users.

Where is Construction Asset Management Headed?

The tracking systems we have today are impressive, but they’re really just the first chapter. What’s coming next will connect job sites in ways that make current operations feel like they’re running in the dark, especially when it comes to the complex dance of transport logistics.

The big change is happening where tracking data meets artificial intelligence (AI) and machine learning. These aren’t just buzzwords; they’re the engines that will turn all that passive location data into smart, active instructions for your entire fleet.

Predictive Maintenance and AI Insights

We've moved from reactive to proactive maintenance, but the next logical leap is predictive maintenance. Forget servicing a machine just because it hit a certain number of engine hours. The systems of tomorrow will use AI to sift through thousands of data points—vibration, temperature, engine load, you name it—to forecast a component failure before it ever happens.

Think about what this means for your transport fleet. A system could flag a potential transmission issue on a low-loader truck before it even leaves the yard, stopping a dangerous and expensive breakdown on the highway in its tracks. Maintenance stops being a chore on a calendar and becomes a real-time, intelligent response.

By constantly analyzing live data streams, AI-powered systems can spot subtle patterns that a human would miss, patterns that signal an impending failure. This gives maintenance crews the chance to get ahead of problems, ensuring equipment is always ready to roll.

The Fully Connected Job Site

The future is a job site where everything is connected, powered by the Internet of Things (IoT). We're not just talking about tracking bulldozers and excavators anymore. Every power tool, every pallet of materials, and even the workers themselves will be part of a single, communicating network.

This creates an environment where logistics just… flow. Picture this: a truck carrying steel beams automatically notifies the crane of its exact arrival time. The crane, in turn, signals its readiness to the crew on the ground, so everyone is in position the moment the truck pulls in. This level of automation eliminates wasted time and transforms transport from a series of disconnected steps into a seamless, integrated workflow.

This kind of integration fine-tunes every single step, from transport and delivery right through to on-site assembly. The equipment tracking system evolves from a simple map into the central nervous system of the entire operation.

The Foundation for Autonomous Machinery

Finally, all this advanced tracking technology is laying the critical groundwork for autonomous and semi-autonomous construction equipment. These machines can’t work in a vacuum; they depend on hyper-accurate positioning and a constant flow of real-time data to navigate a busy site and do their jobs.

A powerful tracking system is what feeds these robotic systems the location and operational data they need to function. It helps manage their transport to and from the site, coordinates their movements with human-operated machines, and keeps them working safely within digital boundaries.

Getting a solid tracking system in place today is more than just an investment in efficiency—it’s preparing your business for the next, inevitable wave of construction technology.

Got Questions? We've Got Answers

Stepping into the world of equipment tracking can bring up a few practical questions. Let's tackle some of the most common ones we hear from managers to help clear things up before you make a move.

What's the Real Cost of These Tracking Systems?

You're typically looking at two main costs. First, there's the upfront price for the physical tracking device itself, which usually runs anywhere from $50 to $300 per unit. Then, you'll have a monthly software subscription that costs between $15 and $40 for each asset you're tracking.

But don't just look at the price tag. Think about the total cost of ownership, which might include installation or training. The real story, though, is the return on your investment. The money you'll save on fuel, more efficient transport logistics, and preventing even a single theft can easily pay for the entire system many times over.

Will This Stuff Work on My Older Equipment?

Yes, absolutely. Most tracking systems today are built to be universal. The hardware is designed to be self-contained and just needs to connect to a power source on your machine. This makes it simple to get location, movement, and engine status from almost any piece of equipment, no matter how old it is.

Newer machines with all the bells and whistles (like a CAN bus system) will give you even more detailed data. But for your trusted older workhorses, you'll still get the core, must-have information like location and engine hours without a problem.

What's the Difference Between GPS Tracking and Telematics?

It's a great question, and the distinction is pretty important for anyone managing transport and logistics.

Here’s the simplest way to think about it: GPS tells you where your equipment is. Telematics tells you where it is and how it's doing.

- GPS Tracking: This is your basic dot on a map. It's fantastic for security and figuring out the best transport routes.

- Telematics: This is the whole story. It uses GPS for location but also pulls in a ton of other useful info—think engine hours, fuel levels, idle time, and even engine fault codes. It gives you a complete health report on your asset.

GPS is about location; telematics is about insight. GPS helps you guide the truck carrying your dozer, but telematics tells you if that dozer will arrive fueled up, healthy, and ready to get to work.

How Hard Is It to Get My Team Trained on a New System?

You’d be surprised how easy it is. Modern systems are designed with the user in mind, featuring clean dashboards and simple mobile apps that don't require a computer science degree to figure out. Any good provider will also walk you through the setup with live training, video guides, and a support team you can actually call.

The secret to getting your crew on board fast is choosing a provider with great customer support. It also helps to show your team how the system makes their jobs easier—no more manual paperwork, automated maintenance reminders, and simpler transport requests. When they see the benefits for themselves, adoption happens pretty quickly.

At We Will Transport It, we know that getting your high-value equipment to the next job site safely and on schedule is critical. While a great tracking system gives you the bird's-eye view, our logistics experts provide the muscle and know-how to get it there. Let us handle the heavy lifting. Learn more about our heavy equipment transport services.