Shipping heavy equipment is a different beast altogether. It's not just about moving something from A to B; it's a complex logistical puzzle involving massive machinery, specialized trailers, and a web of state-by-state regulations. Getting it right comes down to one thing: meticulous planning. Before a single wheel turns, you need to have everything from measurements to permits locked down. This is how you ensure your high-value assets arrive safely, on time, and without any nasty budget surprises.

Your Blueprint for Heavy Equipment Shipping

Moving a bulldozer or a crane is a high-stakes operation where even the smallest oversight can cause massive headaches. Think of this guide as your complete roadmap, built to slice through the complexity and give you a clear, step-by-step plan. We'll tackle the biggest challenges head-on so you have the confidence to manage the entire process.

This goes way beyond just booking a truck. It’s about truly understanding the specific needs of your machine. For instance, a tall excavator will likely need a lowboy or step-deck trailer just to clear highway overpasses. On the other hand, a self-propelled combine harvester often requires a Removable Gooseneck (RGN) trailer so it can be driven on and off safely.

The Foundation of a Successful Shipment

A seamless heavy haul rests on getting a few key things right from the very start. Drop the ball on any one of them, and you could be looking at serious delays, potential damage, or unexpected costs that blow up your project budget.

Here are the actionable steps you must take first:

- Nail the Measurements: Provide the exact, manufacturer-spec dimensions and weight. Being off by even an inch can be the difference between a standard haul and one that needs expensive oversized permits and pilot cars. Use a tape measure and a scale if necessary.

- Pick the Right Team and Trailer: Don’t just hire any carrier. You need a company with proven experience in heavy haulage and the specific trailer for your machine. This is a matter of safety and legal compliance.

- Stay Compliant: Every state has its own rulebook for oversized loads. Your chosen carrier must navigate this patchwork of permits and carry sufficient insurance. Verifying this is a critical risk management step.

The secret to successful heavy equipment shipping isn't finding the cheapest quote; it's investing in thorough preparation. Every hour spent planning saves potential days of delays and thousands in unforeseen expenses.

To give you a better sense of the overall flow, this table breaks down the shipping process into core phases. It's a quick reference for the key actions and goals at each stage of the journey.

Heavy Equipment Shipping At a Glance

| Phase | Key Action | Primary Goal |

|---|---|---|

| Planning & Quoting | Measure equipment, research carriers, get quotes. | Establish accurate project scope and budget. |

| Carrier Selection | Vet carrier experience, insurance, and licensing. | Partner with a reliable and compliant expert. |

| Permitting & Route | Secure all necessary state/local permits. | Ensure a legal and safe route for transit. |

| Preparation & Loading | Prepare equipment for transport, coordinate pickup. | Load the machine safely and securely. |

| Transit & Delivery | Track shipment, manage communication. | Monitor progress and prepare for arrival. |

| Unloading & Inspection | Unload equipment and inspect for any damage. | Complete the delivery and confirm asset condition. |

Understanding these stages helps you anticipate needs and stay ahead of potential issues, making the entire process much smoother.

A Growing Industry

The need for reliable heavy equipment transport is bigger than ever and continues to grow. The global heavy equipment shipping industry is currently valued at around $10 billion and is expected to hit $15 billion by 2033. North America is the biggest player, making up 35% of the total market. This growth just underscores how vital specialized logistics are for keeping construction, agriculture, and energy projects moving forward.

Solid planning and a clear understanding of the logistics are your best tools. Our detailed guide on heavy equipment transportation dives even deeper into managing these complex moves. By following a structured blueprint like this one, you can turn what seems like a daunting task into a well-managed, successful operation.

Prepping Your Machinery for Transport

Getting your equipment ready for the road is your first and best line of defense against damage, delays, and surprise costs. This isn't just a quick once-over; it's a methodical process that protects your investment. A single unsecured component, like a backhoe arm swinging loose on the highway, can lead to absolute disaster.

Think of the following steps as your pre-flight checklist. This is the hands-on work that ensures your machine is safe, secure, and ready for whatever the journey throws at it.

Mechanical and Fluid Preparations

Before that truck even thinks about backing up, your machine needs to be mechanically sound and free of any potential hazards. Leaks and loose parts aren't just messy—they're serious safety violations that can get a shipment shut down and slapped with fines.

A thorough inspection is where you start. When you're prepping your machinery for transport, it's vital to inspect all critical components, including specialized equipment like Fast Fueling Systems, to ensure they are properly secured or drained. This kind of attention to detail is what prevents problems down the road.

Beyond that, hit these key areas:

- Fluid Levels: It’s standard practice to drain most of the fuel to reduce weight and fire risk. A fuel tank that is more than a quarter full can add significant weight and create a sloshing hazard. While hydraulic fluids are usually left in, always confirm with your carrier. They know the regulations for their routes.

- Battery Disconnection: This is a simple but critical safety step. Disconnect the battery and tie back the cables. It completely eliminates the risk of an accidental startup, electrical short, or dead battery on arrival.

- Leak Checks: Get on your hands and knees and look for any oil, coolant, or hydraulic fluid leaks. A tiny drip on your lot can become a major environmental spill on the highway, leaving you on the hook for expensive cleanup fees.

Securing All Loose and Articulated Components

Once you've sorted out the internals, turn your attention to the exterior. Anything on that machine that can move, swing, or fall off is a major liability in transit. Federal Motor Carrier Safety Administration (FMCSA) regulations are crystal clear: all attachments must be adequately secured.

Picture the constant vibration and forces a machine endures over hundreds of miles. If something isn't locked down, it will work its way loose.

An unsecured boom or bucket is one of the most common—and dangerous—oversights in heavy equipment shipping. Always assume that if a part can move, it will move. Lock it down without exception.

To get it right, follow this simple process:

- Lower All Attachments: Place every blade, boom, and bucket in its lowest possible transport position. Doing so immediately lowers the machine's center of gravity and reduces its travel height, making it far more stable.

- Engage Locks: Use every factory-installed travel lock you can find. If the machine doesn't have them, or they're damaged, break out the heavy-duty chains and binders to immobilize everything that articulates.

- Remove or Secure Loose Items: Clear out the cab and any exterior compartments. Toolboxes, spare parts, and even binders not in use can become dangerous projectiles or fall onto the road. If you can't remove it, chain it down.

The Power of Detailed Documentation

Your final prep step is arguably the most important for protecting yourself: documentation. Before the carrier arrives, you need to create an ironclad record of the machine’s condition. This visual proof is your best friend if you ever have to file a damage claim.

Don't just snap a few quick pictures. Be meticulous.

- Timestamped Photos: Use a high-resolution camera and make sure the date and time stamp feature is on. Get shots from every angle—front, back, both sides, top-down. Zoom in on any existing scratches, dents, or scuffs.

- Walk-Around Video: This is a game-changer. Hit record and do a slow walk around the entire machine. Narrate what you see, pointing out the machine's overall condition and calling attention to any pre-existing damage.

- Component Close-Ups: Pay special attention to high-value or fragile parts. Get detailed shots of the cab interior, glass, tires or tracks, the engine bay, and any sensitive electronics.

When the machine is delivered, you'll compare this documentation against the Bill of Lading (BOL). It turns a potential "he said, she said" nightmare into a simple, fact-based conversation.

How to Choose the Right Shipping Carrier

When it comes to shipping heavy equipment, picking the right carrier is about so much more than finding the lowest price. A cheap quote from an inexperienced operator can quickly spiral into a costly nightmare of delays, damaged machinery, or legal trouble. Your goal is to find a true heavy-haul specialist who understands the regulations and your specific machinery inside and out.

This means you’ve got to do your homework. A reputable carrier will be an open book, ready to provide all the documents you need to prove they're qualified for the job. Rushing this vetting process is easily one of the biggest—and most expensive—mistakes you can make.

Verifying Carrier Credentials

Before you even start talking numbers, your first move is to confirm the carrier is legally authorized and has a clean safety record. This isn't just a box to check; it’s your primary defense against a fly-by-night company that could put your six-figure asset at risk.

Thankfully, the Federal Motor Carrier Safety Administration (FMCSA) makes this easy.

Ask for the carrier’s MC (Motor Carrier) and USDOT (U.S. Department of Transportation) numbers. Then, plug those numbers into the FMCSA's SAFER database. This provides a snapshot of their operational status, safety rating, and inspection history. A carrier with a "Satisfactory" rating and a low out-of-service percentage is a great start.

Beyond that initial check, here’s a practical checklist:

- Active Authority: Confirm their operating status is "Authorized for property" and not flagged as "Out-of-Service."

- Sufficient Insurance: At a bare minimum, they need $100,000 in cargo insurance. For anything more valuable, you'll need higher coverage. Demand a copy of their insurance certificate and verify the policy limit and effective dates.

- Proven Experience: Ask for references or case studies of similar hauls they've completed. A carrier that moves bulldozers every day will understand the challenges in a way that a general freight company might not.

Matching Equipment to the Right Trailer

Getting the trailer right is a non-negotiable part of the puzzle. The trailer must be a perfect match for your machine's weight, height, and loading needs to ensure a safe and legal haul. The wrong choice can lead to bridge strikes, rollovers, or hefty permit violations.

For instance, a standard flatbed is completely wrong for a tall excavator, which would almost certainly be over the legal height limit. For that, you need a step-deck trailer with its lower main deck to gain crucial overhead clearance.

For a large dozer that has to be driven onto the trailer, a Removable Gooseneck (RGN) trailer is often the only safe option. The front of an RGN detaches, creating a sturdy ramp that allows heavy, tracked equipment to be driven on and off with minimal risk.

A true pro won't just ask for your machine's model number. They’ll ask for its exact operating weight and all three dimensions—length, width, and height. That level of detail is a dead giveaway that you're dealing with someone who takes safety seriously.

To make the choice clearer, here’s a quick guide to help you match your machine to the right trailer type.

Matching Your Equipment to the Right Trailer

Use this table to quickly identify the best trailer for your machine based on its specific dimensions, weight, and how it needs to be loaded.

| Trailer Type | Best For | Key Advantage |

|---|---|---|

| Standard Flatbed | Shorter, lighter equipment; items that can be crane-loaded. | Versatile and widely available for standard loads. |

| Step-Deck (Drop-Deck) | Equipment up to 10 feet tall that needs extra overhead clearance. | Lower deck height than a flatbed prevents over-height issues. |

| Removable Gooseneck (RGN) | Tall, heavy, and self-propelled equipment like bulldozers or excavators. | Detaches to create a ramp for easy and safe drive-on loading. |

| Lowboy | The heaviest and tallest machinery, like large cranes or mining equipment. | Sits extremely low to the ground for maximum height clearance. |

Choosing the correct trailer is a foundational step that influences everything from route planning to permit requirements, so it's critical to get it right from the start.

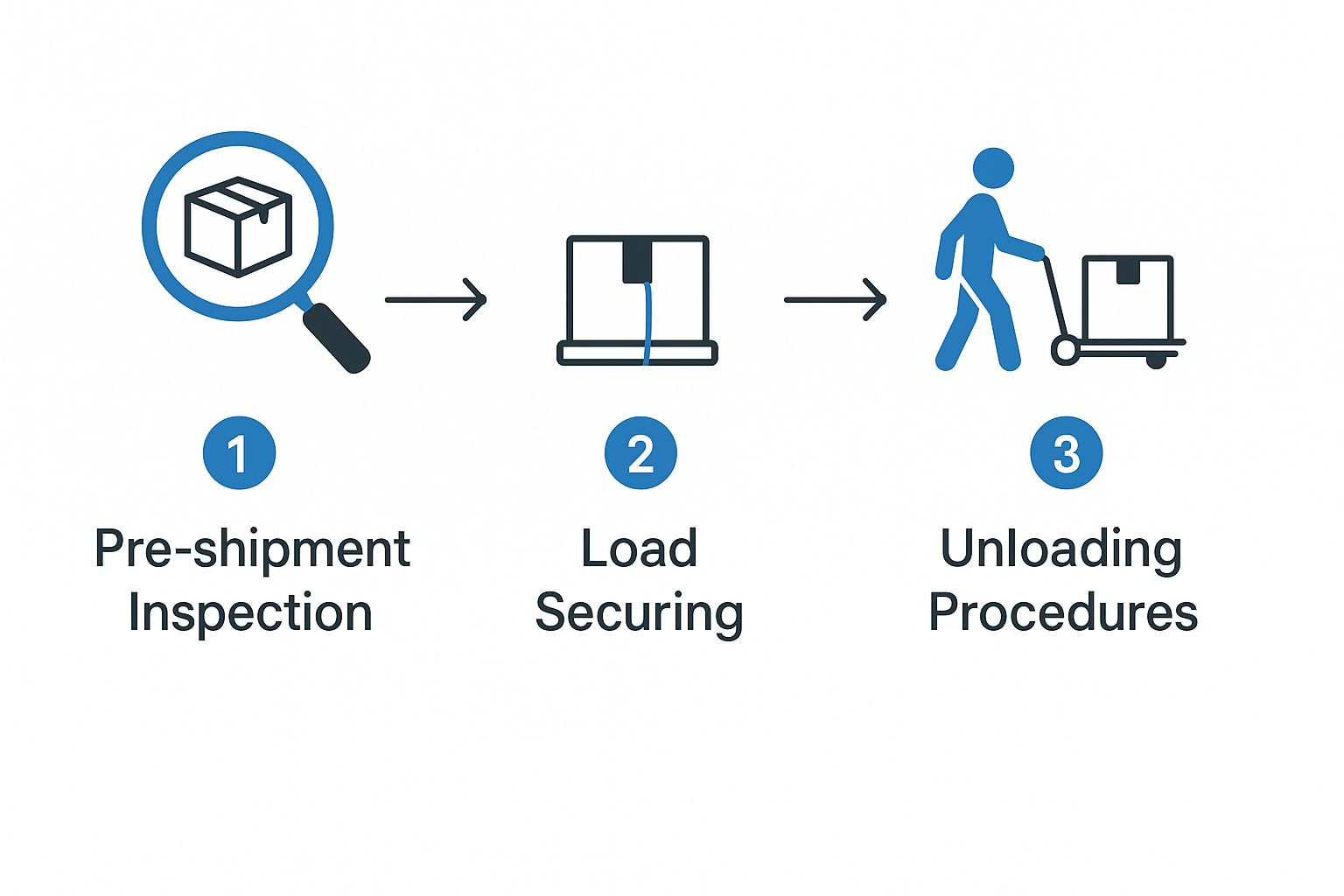

This process—from pre-shipment checks to securing the load and final delivery—shows how each step is built on the last to guarantee a safe trip.

Asking the Right Questions

Once you have a shortlist of vetted carriers, it’s time to dig in with some pointed questions. How they respond will tell you everything you need to know about their experience and whether they're the right partner for your job. A seasoned carrier will have direct, confident answers.

Make sure you get clear answers on these points:

- Who handles the permits? A professional heavy-haul carrier should manage all oversize and overweight permitting as part of their service. This is a tangled web of state-by-state rules you want an expert navigating.

- What is your process for route planning? How do they account for low bridges, road construction, or state-specific travel curfews for oversized loads? A good answer involves specialized software and deep logistical knowledge.

- Can you walk me through your insurance coverage? Don’t just settle for the dollar amount. Ask what their cargo insurance actually covers and, more importantly, what it excludes.

The heavy equipment shipping market is projected to see steady growth of around 1.6% to 1.7% annually through 2033, showing it's a mature industry built on reliability. The major players in this space thrive because of their specialized knowledge and extensive networks. You can discover more about the heavy equipment shipping market to get a better feel for the industry. This stable growth just goes to show how critical it is to partner with established, professional carriers who are in it for the long haul.

Getting Your Paperwork in Order: Permits and Insurance

The maze of permits and insurance is where a smooth heavy haul can quickly turn into a nightmare. Getting this part right isn't just a suggestion; it’s what stands between a successful delivery and crippling fines, your equipment being impounded, or a catastrophic financial loss.

Imagine moving a combine harvester three states over. You aren't just booking a truck. You're orchestrating a complex move that requires state-specific permits, pilot cars, strict travel hours, and a pre-approved route to sidestep low bridges and weak roads. This is a logistics challenge best left to experts.

Demystifying Oversize and Overweight Permits

The moment your loaded equipment exceeds standard dimensions, you’re in permit territory. The numbers to watch for in most states are 8.5 feet wide, 13.5 feet high, or a gross vehicle weight of 80,000 pounds. If your shipment crosses any of those lines, you absolutely need special permission to hit the road.

The biggest challenge is that there's no universal federal permit. Each state has its own Department of Transportation (DOT) with its own rules, fees, and application processes.

- State-by-State Hassle: A permit from Texas won’t do you any good once you hit the Oklahoma state line. Your carrier has to pull a new permit for every state the truck passes through.

- Locked-in Routes: Permits specify the exact highways a truck must use, all planned to protect public safety and infrastructure.

- Time and Day Restrictions: Many states limit oversize travel to daylight hours and ban it entirely on weekends or holidays to keep traffic flowing smoothly.

This is precisely why you lean on an experienced heavy-haul carrier. They navigate this red tape every day, ensuring your shipment remains compliant from start to finish.

Don't Get Burned by the Wrong Insurance

Here’s a common and costly mistake: assuming the carrier’s basic liability coverage is enough for a six-figure machine. It almost never is. You must understand the difference between standard liability and the real cargo insurance your asset needs.

Carrier liability isn't traditional insurance. It’s a bare-minimum legal requirement that often pays out a negligible amount based on weight, not the actual value of your equipment. It's riddled with exclusions and designed to cover only the most basic damages.

Never assume a carrier's standard policy covers the full replacement cost of your equipment. The first thing you should do is ask for a certificate of cargo insurance and make sure the coverage amount is higher than your machine's value.

To truly safeguard your investment, the carrier must have a solid cargo insurance policy. This is the policy designed specifically to cover the value of the freight itself. Before you sign anything, demand to see a copy of their insurance certificate and check that policy limit yourself.

Protecting Your Financial Interests

Safeguarding a piece of high-value equipment is about more than just the trip itself. While getting the permits and insurance right is non-negotiable for the haul, it's also smart to look into broader effective asset protection strategies to cover your valuable machinery from every angle.

This kind of proactive thinking is vital, especially when you see where the industry is heading. The heavy construction equipment market, which directly fuels our shipping world, is projected to jump from $177.4 billion in 2025 to a staggering $328.5 billion by 2033.

That growth is being driven by huge infrastructure projects happening all over the globe, which means more high-dollar equipment will be on our roads than ever before. Having bulletproof insurance and perfect permit compliance isn't just good practice—it's essential for protecting these vital, expensive assets.

Where the Rubber Meets the Road: Managing Loading and Delivery

This is it—the point where all your planning is put into action. The loading and unloading of your machine are the highest-risk moments in the entire shipping process. A successful handover boils down to three actionable items: a well-prepared site, clear communication with your driver, and a meticulous final inspection.

First, prepare your pickup and delivery sites. A long, heavy trailer needs a surprising amount of space to maneuver, not to mention solid ground to sit on. Before the truck is en route, walk the area. Is the ground firm and level? Is it clear of mud, debris, or any low-hanging power lines? An unstable surface can turn a routine load into a dangerous situation.

Communicate with your driver. A quick call while they're en route to go over the site layout, point out any tight spots, and confirm placement can prevent a world of headaches. This simple conversation makes the whole process run like clockwork.

Your On-Site Crew and Gear

Having the right people and equipment ready to go is absolutely critical for a safe transfer. Your driver's job is to secure the machine to the trailer, but getting it there and preparing the site is your responsibility.

Make sure you have the right team assembled for the scheduled arrival time:

- A Certified Operator: Someone qualified to drive the machine onto or off the trailer.

- A Spotter: A second set of eyes on the ground is invaluable for guiding the operator and watching clearances.

- Support Staff: For complex jobs involving cranes or specialized lifts, you'll need a dedicated crew. A solid understanding of rigging and lifting heavy equipment isn't just helpful—it's essential for safety.

Any necessary assistance, like a portable loading ramp or a forklift, should be in place and ready to go before the truck arrives to ensure a smooth and efficient transfer.

The Final Walk-Around and the Bill of Lading

Once your equipment is safely on the ground at its destination, it’s time for the final inspection. This is your last, best chance to formally document the condition of your machine. Do not let anyone rush you through this step.

Pull out the timestamped photos and videos you took before loading. Do a slow, methodical walk-around, comparing the machine's current state to your "before" documentation. Look for any new scratches, dents, or other signs of damage that might have occurred in transit.

Your signature on the Bill of Lading (BOL) is everything. Once you sign a clean BOL, you are legally confirming you received the equipment in perfect condition. Trying to file a damage claim after that is next to impossible.

If you find any discrepancy, you must note it directly on the Bill of Lading before you sign it.

- Be Specific: Don't just write "damaged." Note exactly what and where the issue is. For example, "6-inch scratch on right side of boom" or "dent in left rear fender."

- Take More Photos: Document the new damage right then and there. Make sure the driver sees you doing it.

- Sign After You Note: Once you’ve added your notes to the BOL, then you can sign. This creates an undeniable record that the damage was present upon delivery.

This diligent process protects your investment and ensures your carrier is held accountable. By managing the site, communicating well, and performing a thorough final inspection, you close out your shipment with confidence.

Answering Your Heavy Equipment Shipping Questions

Even with a solid plan, questions will arise. Getting straight answers to these common queries is key to avoiding expensive mistakes and managing your transport with confidence.

Here are the actionable answers to the questions we hear most often.

How Is the Cost of Heavy Equipment Shipping Calculated?

There's no simple flat rate for a heavy haul. The final price is a blend of several factors that determine the job's complexity and resource requirements.

The core factors are always distance, equipment dimensions (length, width, height), and total weight. These three numbers form the foundation of any quote.

Other variables that impact the final cost include:

- Permits and Escorts: Oversized or overweight loads require special state permits. Larger loads often need pilot cars (escorts), which significantly increases the cost.

- Trailer Type: A specialized Removable Gooseneck (RGN) trailer costs more to book than a standard flatbed because it's less common and designed for specific, heavy loads.

- Route Complexity: Moving equipment through a dense city or to a remote rural job site can drive up the cost due to access challenges and specific routing needs.

- Urgency: Expedited shipping will always come with a premium price tag compared to a standard, well-planned move.

What Is a Bill of Lading and Why Is It So Important?

The Bill of Lading (BOL) is the most critical document in the shipping process. It is a legally binding contract between you (the shipper) and the carrier.

The BOL serves three key functions:

- Contract: It outlines the terms of the shipping agreement.

- Receipt: It proves the carrier has taken possession of your machine.

- Title Document: It can represent ownership of the equipment while in transit.

When the driver arrives for pickup, you both inspect the equipment and sign the BOL, agreeing on its current condition. The same process happens at delivery. If you see any new damage upon arrival, you must note it on the BOL before signing.

A "clean" Bill of Lading—one signed at delivery without any damage notes—is a legal declaration that your equipment arrived in perfect shape. Trying to file a successful insurance claim after signing a clean BOL is next to impossible.

Can I Ship Personal Items or Parts Inside My Heavy Equipment?

The answer is a firm no. It is a bad practice to ship personal items or loose parts inside the cab or storage compartments of your equipment.

Carrier insurance is there to cover the machine itself—the item explicitly listed on the BOL. It does not cover any personal belongings or loose parts left inside. If those items are damaged or go missing, the carrier has no legal responsibility for them.

Furthermore, loose items can become projectiles during transit, causing damage to the cab's interior, windows, or controls. Any separate attachments like buckets or blades must be listed on the BOL and secured properly to the trailer to ensure they are covered and arrive safely.

How Much Advance Notice Should I Give a Shipping Company?

When it comes to shipping heavy equipment, the more notice you can give, the better. While last-minute jobs are sometimes possible, they are always more expensive and logistically challenging.

As a rule of thumb, provide your carrier with at least one to two weeks of advance notice. This gives them adequate time to handle the logistical details of a heavy haul, including:

- Scheduling the correct truck and trailer for your specific machine.

- Mapping out the safest, most efficient route that avoids low bridges or road restrictions.

- Securing all necessary state and local permits for an oversized load.

The permit process alone can take several business days, especially for multi-state moves. Planning ahead ensures all paperwork is handled correctly, preventing frustrating and expensive delays at state lines.

When you're ready to move your valuable machinery, trust the experts who understand the details. We Will Transport It offers nationwide heavy equipment shipping services backed by years of experience, ensuring your assets arrive safely and on time. Get your free, no-obligation quote today at https://www.wewilltransportit.com.