To effectively manage shipping costs, you must master the fundamentals. Before considering surcharges and special fees, understand that every shipping quote is built on three core pillars: weight, dimensions, and distance.

Getting these three elements right is the critical first step. Accuracy here leads to precise pricing and protects your profit margins. Any miscalculation introduces guesswork and financial risk.

The Building Blocks of Your Shipping Price

Determining your base shipping rate is a straightforward process of collecting key data about your package. Each piece of information directly impacts the final price.

All carriers, from USPS to FedEx, start with the same basic data. Many businesses face unexpected adjustment fees simply by overlooking one of these details. A firm grasp of this process is essential for mastering your shipping cost calculator and maintaining your budget.

Before you can get an accurate quote, you must gather specific data. The table below details what you need and explains its importance.

Table: Key Factors for Calculating Shipping Costs

| Factor | What It Means for Your Shipment | Why It's Critical for Cost |

|---|---|---|

| Actual Weight | The total weight of the package in pounds or ounces, including all contents, the box, and packing materials. | Heavier packages require more fuel and resources to transport, directly increasing the shipping cost. |

| Dimensions | The precise length, width, and height of your package, measured in inches. | Carriers use these measurements to calculate "dimensional weight." Large, lightweight items can be billed at a higher weight based on their size. |

| Shipping Zone | A numerical value representing the distance from the shipment's origin to its final destination. | The farther a package travels, the higher the cost. Domestic US shipments typically fall into zones 1 through 8. |

Having these three pieces of information is the absolute minimum required to begin any shipping calculation. They are the foundation upon which all other fees and surcharges are added.

The Three Core Shipping Factors

Your first action is always to measure and weigh the package. A reliable digital shipping scale is non-negotiable; estimating or using a bathroom scale invites costly errors. Even a few ounces of inaccuracy can result in carrier-imposed adjustment fees that erode your profits.

Let's apply this with a practical scenario.

Imagine you sell handmade ceramic mugs. An order arrives from a customer several states away. Here is your actionable process:

- Weigh the packaged mug: Place the sealed, ready-to-ship box on your digital scale. It reads 2.5 pounds. Carriers round up, so you must use 3 pounds for your calculation.

- Measure the box: Use a tape measure to get the exact dimensions: 6" x 6" x 6".

- Find the shipping zone: You are shipping from your location (Zone 1) to the customer's address, which falls into Zone 5.

With this data—3 pounds, 6x6x6 dimensions, and a Zone 5 destination—you have the necessary information to get a base rate from any carrier. This is your core cost before any additional fees are applied.

Why Dimensional Weight Catches Businesses Off Guard

If you've ever been shocked by the high cost of shipping a lightweight but large item, like pillows or a lampshade, you've encountered dimensional weight.

This pricing model, often called DIM weight, is a primary source of unexpected shipping charges. It's a method that can transform a seemingly inexpensive shipment into a significant business expense.

Carriers don't just charge for how heavy your package is; they charge for the space it occupies in a truck or aircraft. For transport companies like FedEx and UPS, cargo space is their most valuable asset. A truck full of large, light boxes of potato chips is just as "full" as one with small, heavy boxes of weights. Charging only by actual weight would make bulky, light items unprofitable to transport.

The Logic Behind Charging for Space

Dimensional weight was created to ensure carriers are compensated fairly for the volume each package consumes. This prevents financial losses on items that are light but occupy substantial space.

From the carrier's perspective, a large, mostly empty box still prevents another package from occupying that same spot. By calculating a DIM weight, they establish a "billable weight" based on a package's size.

Actionable Insight: The carrier will compare your package's actual weight to its calculated dimensional weight and charge you for whichever is greater. This practice guarantees that every cubic inch of their cargo space generates revenue.

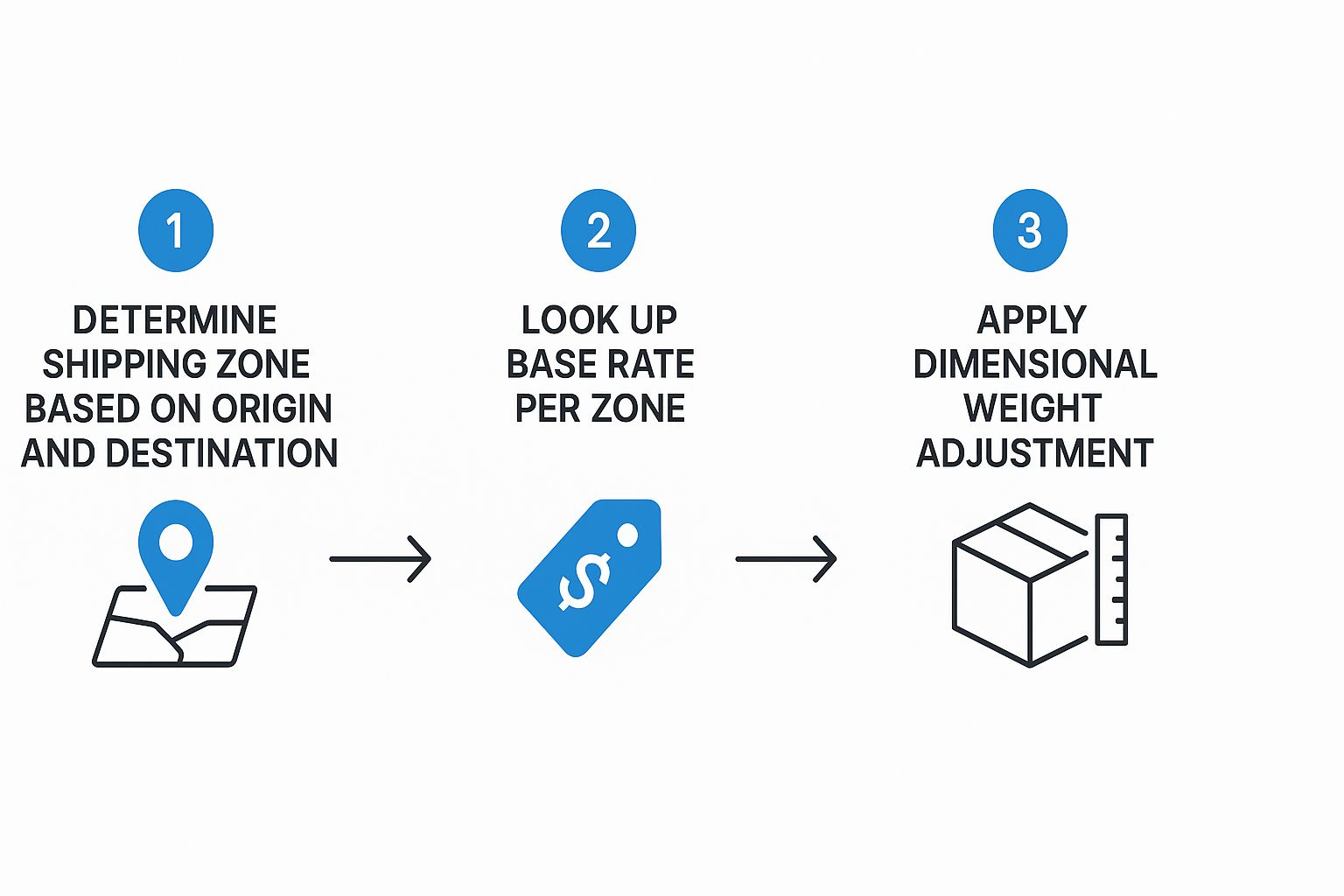

This image illustrates where DIM weight fits into the overall cost calculation.

As shown, after determining the base rate and shipping zone, applying the DIM weight is a critical step that can significantly increase your final shipping cost.

How to Calculate Dimensional Weight

The formula is simple, but the "DIM divisor" used in the calculation varies by carrier, a detail that frequently trips up businesses.

The basic formula is:

(Length x Width x Height) / DIM Divisor = Dimensional Weight

Let’s apply this. Imagine you are shipping a decorative pillow. The box measures 20" x 20" x 10", and the actual weight of the package is only 4 pounds.

Here’s how major carriers would calculate the billable weight:

- UPS & FedEx (Daily Rates): Their standard DIM divisor is 139.

- (20 x 20 x 10) / 139 = 4,000 / 139 = 28.77 lbs.

- USPS (Priority Mail & Ground Advantage): The USPS uses a more favorable divisor of 166.

- (20 x 20 x 10) / 166 = 4,000 / 166 = 24.09 lbs.

Carriers round up to the next whole pound. With UPS or FedEx, you are not paying to ship a 4-pound package; you are paying to ship a 29-pound package. This represents a seven-fold increase in billable weight and can severely impact your profit margin.

To avoid these costs, your primary goal must be to use the smallest possible box that ensures product safety. For soft goods like apparel, a poly mailer is a more cost-effective choice than a box. By minimizing package dimensions, you stop paying to ship empty space and keep your transport costs under control.

How to Navigate Surcharges and Hidden Fees

You’ve calculated your base shipping rate using weight, dimensions, and distance. However, that rate is only the beginning.

The real threat to your budget comes from surcharges and accessorial fees. These additional charges can inflate a final shipping bill by 25% or more for unprepared businesses. Carriers apply these fees for any service that deviates from a standard, business-to-business delivery.

Learning to anticipate and mitigate these fees is crucial for protecting your profit margins.

Common Surcharges and How to Dodge Them

Proactively managing surcharges before they appear on your invoice is a powerful cost-control strategy. With foresight, many of these fees are entirely avoidable.

Here are the most common transport surcharges:

- Residential Surcharge: Delivering to a home costs more than delivering to a business because residential routes are less dense and therefore less efficient.

- Fuel Surcharge: This fee fluctuates with fuel prices. While unavoidable, it must be factored into your shipping budget and financial forecasts.

- Delivery Area Surcharge (DAS): This fee applies to deliveries in remote or rural locations to cover the extra time and fuel required.

- Address Correction Fee: A simple typo in an address requires manual intervention by the carrier, and they pass that cost directly to you.

Your best defense against these fees is a proactive offense. Double-check all addresses for accuracy and understand your customers' locations to save a significant amount of money on every shipment.

Practical Ways to Cut Down on Extra Fees

Identifying potential fees is the first step; actively avoiding them is the next.

For example, you can eliminate the residential surcharge by offering customers the option to pick up their package at a carrier access point, such as a UPS Store or FedEx Office. This converts a costly residential delivery into a more affordable commercial one.

This becomes even more critical for large-scale transport. When arranging vehicle transport, for instance, you must find a good car shipping service that provides transparent pricing on all potential fees, such as those for inoperable vehicles or special handling requirements.

Stay aware of broader industry trends. Freight costs are highly volatile. Ocean shipping costs for a 40-foot container tripled in late 2023 due to global supply chain disruptions. By mid-2024, peak season rates exceeded $8,000 per container as businesses began early stockpiling. These are the kinds of market swings that must be built into your financial models.

By anticipating these charges and implementing a plan to address them, you can create a more predictable and profitable shipping operation. Make it a regular practice to review carrier invoices line by line. Recurring fees are clear indicators of process inefficiencies that need to be fixed.

How Global Events Can Upend Your Shipping Budget

Calculating shipping costs is no longer a simple equation of weight and distance. The rates you pay are now directly influenced by a complex web of global events, from geopolitical conflicts to supply chain disruptions, that can cause prices to surge unexpectedly.

Ignoring these external forces leaves your profit margins vulnerable. A single disruption in a major transport channel creates a ripple effect impacting businesses of all sizes. Understanding this bigger picture is a non-negotiable part of how you calculate shipping costs today.

A Real-World Example: The Red Sea Rerouting

The recent disruptions in the Red Sea provide a clear case study. When major shipping lines rerouted vessels around Africa’s Cape of Good Hope to avoid conflict, the impact was immediate. This single event added weeks to transit times, dramatically increased fuel consumption, and threw global container availability into chaos.

The logistical fallout was severe. The sharp rise in 2025 ocean freight rates is a direct result of this supply-and-demand imbalance. When easing U.S.-China tariffs led to a sudden surge in exports from Shanghai, freight rates on some routes jumped by as much as 300%.

The Red Sea crisis, which extended journeys by 10 to 21 days, further compounded the issue by reducing the total number of available trips, forcing carriers to charge more to cover their higher operational costs. You can learn more about how this inflates landed costs at eco-greenenergy.com. This demonstrates how a regional conflict can directly increase transport costs for a business thousands of miles away.

How to Build a More Resilient Shipping Strategy

While you cannot control global events, you can build a shipping operation resilient enough to withstand these shocks. Waiting for a crisis to develop a response is a recipe for failure. Proactive planning is your most effective defense.

Actionable Insight: Stop viewing shipping costs as fixed. You must incorporate a "risk premium" into your financial forecasting to buffer against sudden, unpredictable price increases driven by external factors.

This strategy begins with diversifying your carrier relationships. Move beyond relying on a single transport provider. By cultivating relationships with a mix of national, regional, and local carriers, you create options. When one shipping lane becomes unreliable or prohibitively expensive, you will have alternatives ready.

Finally, proactive communication is essential. When a global event causes unavoidable delays, inform your customers immediately. Explain the situation, how it might affect their delivery, and provide realistic updates. This transparency builds trust and can turn a potential negative experience into an opportunity to strengthen customer loyalty.

Smarter Ways to Find and Reduce Your Shipping Costs

Knowing how to calculate shipping costs is foundational, but actively reducing them is how you protect your profit margins. It's time to leverage powerful tools and strategies that go beyond basic carrier website calculators.

Using a carrier's website for a quote provides only a narrow view of your options. The real leverage comes from using multi-carrier shipping software like ShipStation or Shippo. These platforms allow you to instantly compare all available shipping options in a single dashboard, often unlocking discounted rates you cannot access directly.

Use Technology to Unlock Better Rates

Multi-carrier shipping platforms are a game-changer for any business. They centralize your orders and enable you to comparison-shop for the most cost-effective rate for every single shipment.

A key benefit of these platforms is immediate access to pre-negotiated, discounted shipping rates. These rates are typically much lower than retail or counter rates, providing an instant reduction in your transport overhead.

Proactive Strategies to Lower Your Transport Expenses

Software is only one component. Smart operational adjustments can also significantly reduce your transport expenses. As your shipping volume increases, negotiate rates directly with your carrier representatives. Consistent business provides powerful leverage for securing better pricing.

Here are other effective tactics:

- Look into Regional Carriers: For local or in-state deliveries, regional carriers often offer faster service at a lower price point than national competitors.

- Distribute Your Inventory: Storing products in multiple fulfillment centers across the country is a strategic move that reduces shipping zones, thereby lowering costs and speeding up delivery times.

For a broader perspective on business savings, explore these proven strategies to reduce operating costs.

The best shipping strategies are dynamic, not static. They must adapt to your business growth and evolving market conditions. Staying informed about freight trends allows you to anticipate cost changes rather than simply reacting to them.

This agility is crucial in the current transport landscape. Despite market volatility, some international freight rates have recently decreased. For example, in mid-2025, ocean rates from Asia to the U.S. West Coast fell by approximately 10% due to shifts in fleet capacity and demand. However, these rates remain significantly higher than pre-pandemic levels, underscoring the need for highly responsive cost models.

Even for complex, specialized shipments, strategic planning is key. We outline the factors involved in our guide on how much it costs to ship a car internationally. By combining the right technology with smart logistical planning, you can transform shipping from a major expense into a competitive advantage.

Common Questions About Calculating Shipping Costs

Even with a solid understanding of the formulas, practical questions will always arise. Addressing these common issues is the final step in building a shipping strategy that truly works for your business.

Here are answers to the most frequent questions from business owners seeking to control their shipping costs.

What Is the Absolute Cheapest Way to Ship Something?

The answer depends on two variables: weight and speed.

For lightweight items under one pound—such as jewelry, stickers, or a single t-shirt—USPS Ground Advantage is unbeatable. Formerly known as First-Class Package, it remains the most cost-effective method for moving small, light packages.

Once a package exceeds one pound, the cost dynamics shift. Ground services from carriers like UPS and FedEx become more competitive, especially for heavier items. If delivery time is not critical, a ground shipping option is almost always the cheapest choice.

How Can I Offer Free Shipping Without Losing Money?

"Free shipping" is a powerful conversion tool—research indicates that 93% of shoppers will add items to their cart to qualify for it. The key is to implement it profitably.

The most effective strategy is setting a minimum order threshold. This encourages customers to increase their cart size, raising your Average Order Value (AOV) to a point where it absorbs the shipping cost. To set the right threshold, you must know your average shipping cost and profit margin.

Another practical approach is to incorporate a portion of the shipping cost into your product prices. A small, distributed price increase across your catalog is less noticeable to customers than a separate shipping fee at checkout.

"Free shipping" is never truly free; the cost is simply absorbed elsewhere. Your objective is to structure offers so that the resulting increase in sales and AOV more than compensates for the shipping expense.

How Often Should I Re-evaluate My Shipping Strategy?

Shipping is not a "set it and forget it" operation. Conduct a comprehensive review of your entire shipping strategy at least annually. Carriers typically implement rate increases every January, and failure to adjust your pricing or thresholds will directly impact your profitability.

In addition to the annual review, a quarterly check-in is advisable. This is an ideal time to identify new surcharges, assess carrier performance, and confirm that your current setup remains the most cost-effective. For more complex logistics, such as determining auto transport costs, more frequent evaluations may be necessary to keep pace with market fluctuations.

When your shipment is larger than a standard package, you need a transport expert you can trust. We Will Transport It specializes in the complex logistics of moving vehicles, heavy equipment, and oversized freight, ensuring your most valuable assets arrive safely and on schedule. Get a free, no-obligation quote today!