When you need to move something truly massive—think a giant mining excavator, a house-sized generator, or a wind turbine blade that stretches a hundred feet—a regular flatbed truck just isn't an option. This is where low loader transport comes in. It’s the go-to solution for hauling cargo that's not just heavy, but also exceptionally tall or wide.

The secret is in the name. A low loader's deck sits much closer to the ground, giving you the extra vertical clearance needed to navigate under bridges, power lines, and other overhead obstacles that would otherwise make a route impossible. This guide provides actionable insights for planning, budgeting, and executing a successful heavy haul.

What Exactly is Low Loader Transport?

Think of it like trying to get a tall piece of furniture through a standard doorway. You have to tilt it and lower it to make it fit. A low loader trailer uses that same basic idea for logistics. It’s not simply a larger truck; it’s a piece of specialized engineering designed from the ground up to solve the puzzle of moving enormous objects.

This clever design is what makes it possible to transport equipment that would otherwise be stuck, unable to move safely or legally on public roads. It's an indispensable workhorse for industries like construction, agriculture, mining, and energy.

Core Design and Purpose

The most obvious feature of a low loader is its split-level deck. You have a raised section that sits over the truck's fifth-wheel coupling, and then the main deck drops down significantly, running the length of the trailer.

A low loader trailer is purpose-built to maximize vertical clearance. By positioning the load closer to the ground, it creates the extra space needed to clear overhead obstacles, making previously impossible routes viable.

This design is a direct answer to the biggest headache in heavy haulage: height restrictions. Without it, many of the essential machines that build our cities and power our world would be stranded. You can see how this works for different types of machinery in our detailed guide on heavy equipment transport.

To better understand what makes these trailers so effective, let's look at the features that set them apart.

Key Features of Low Loader Trailers

| Feature | Description | Primary Benefit |

|---|---|---|

| Gooseneck | The curved section connecting the trailer to the truck. Many are detachable. | A detachable gooseneck (RGN) creates a ramp for machinery to be driven on and off. |

| Low-Profile Deck | The main loading platform, which sits extremely close to the ground. | Maximizes vertical space, allowing for the transport of taller-than-average cargo. |

| Multiple Axles | A high number of axles at the rear of the trailer, often more than a standard semi. | Distributes immense weight evenly, complying with road regulations and preventing damage. |

As you can see, every part of the design serves a critical purpose.

These specialized trailers are the backbone of the heavy haulage industry, making it possible to move the biggest and bulkiest loads. If you want to see the wide range of applications, many companies offer specialised haulage services that showcase just how versatile these vehicles are.

With infrastructure projects booming worldwide, the demand is only growing. The global low loader market was valued at USD 2.5 billion in 2024 and is expected to climb to USD 4.1 billion by 2033. This growth highlights just how vital this equipment is to modern industry. You can dig into more of the numbers and trends in this market report from Verified Market Reports.

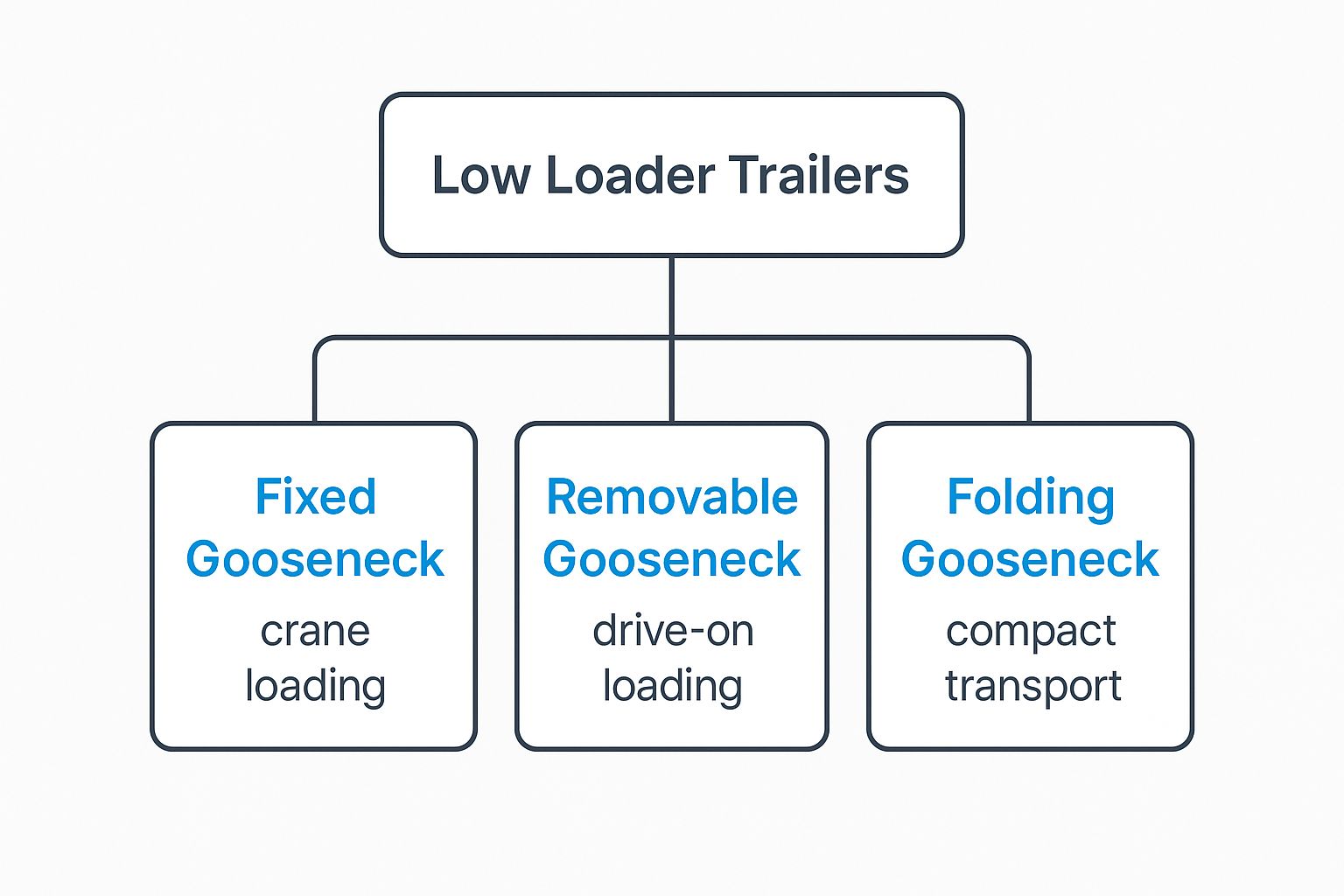

Choosing the Right Type of Low Loader Trailer

Picking the right low loader is the most critical decision in heavy haulage, directly impacting safety, cost, and timeliness. This isn't a one-size-fits-all game. The trailer must match the cargo, loading site, and route. A mismatch can lead to safety hazards, project delays, and unexpected costs.

For example, selecting a trailer that requires crane loading for a piece of driveable machinery wastes time and money. Understanding the basic trailer types is the first step toward making a smart, safe, and cost-effective decision.

Fixed Gooseneck (FGN) Trailers

The most straightforward and often lightest option in the fleet is the Fixed Gooseneck (FGN) low loader. Just like the name implies, its gooseneck—that's the part that arches up and over the truck's rear wheels—is permanently welded to the trailer frame. This simple, rugged design means fewer moving parts, which translates to a lighter trailer.

Of course, since the gooseneck doesn't come off, you can't just drive equipment onto the front of the deck. Loading an FGN almost always involves a crane to lift the cargo and set it down on the trailer bed. This makes FGNs a great choice for static items like crated factory machines, big steel beams, or any equipment that can't move on its own.

This infographic gives you a quick visual breakdown of how low loaders are classified by their loading style.

As you can see, the gooseneck design is really what defines the trailer's job, splitting them into two camps: crane-loaded and drive-on.

Removable Gooseneck (RGN) Trailers

When it comes to hauling mobile heavy equipment, the Removable Gooseneck (RGN) trailer is the undisputed king. Its design completely changes the game for safely and efficiently loading machinery that can drive itself. The entire gooseneck assembly unhooks from the trailer and is driven away with the truck.

What this does is drop the front of the trailer deck right to the ground, creating its own built-in ramp. Heavy hitters like excavators, bulldozers, road pavers, and massive farm tractors can simply be driven right on. Once the cargo is chained down, the truck backs up, reattaches the gooseneck, and uses its hydraulics to lift the trailer back to travel height.

The real magic of the RGN is that it cuts out the need for separate cranes or clunky loading ramps. This makes it incredibly versatile for construction sites, farms, and mines where you can't count on having a fully-equipped loading dock.

This feature doesn't just save a ton of time; it dramatically cuts down on the risks that come with trying to lift heavy, awkward loads. If you're moving this kind of machinery, you can get a deeper dive into what these trailers can do and learn more about RGN trailer transport services.

Folding Gooseneck Trailers

A clever spin on the RGN is the Folding Gooseneck trailer. Instead of the neck detaching completely, it's hinged and folds down flat onto the ground, forming a full-width ramp. This design is usually much faster to set up than a standard RGN because the operator never has to disconnect the neck from the trailer.

The main perks of a folding gooseneck are speed and simplicity. An operator can drop the ramp in moments without the hassle of lining the truck up perfectly to reconnect a detached neck.

- Key Advantage: It creates a wide, sturdy ramp that’s great for both wheeled and tracked equipment.

- Best Use Case: Perfect for jobs with a lot of loading and unloading, where every minute counts.

The trade-off? The folding mechanism can be a bit longer and heavier than a detachable neck. This might slightly reduce your usable deck space or payload capacity when compared to a similar RGN. At the end of the day, whether you need an FGN, RGN, or a folding gooseneck all comes down to the specific machine you’re moving and the conditions at your pickup and drop-off points.

Industries That Run on Low Loader Transport

Low loader transport is more than just logistics; it's the circulatory system for heavy industry. Without these specialized trucks, the foundational work of construction, energy, and agriculture would grind to a halt.

To understand their impact, let's move beyond technical specs to see how low loader transport solves unique and complex problems every day through real-world applications.

Powering the Future with Renewable Energy

Picture this: a massive wind turbine blade, stretching over 200 feet long, sits at a factory. Its destination? A remote, windswept hilltop hundreds of miles away, only reachable by a network of narrow, rural roads. This isn't a job for your standard flatbed. It's a logistical ballet that depends entirely on the right low loader.

The blade is carefully secured to an extendable trailer, specifically built to handle its extreme length. The route has been planned with almost surgical precision, mapping out every tight corner, low bridge, and overhanging power line. As the truck navigates those winding country lanes, its low-slung deck provides those crucial extra inches of clearance—the very thing that separates a safe delivery from a catastrophic failure.

This single trip perfectly illustrates how low loaders conquer the challenge of extreme dimensions, making sure our green energy infrastructure gets built.

And the demand for this is exploding. The global market for low-loader trailers was pegged at around USD 5 billion in 2025 and is on track to grow by about 6% each year through 2033. This isn't surprising, given the boom in infrastructure projects worldwide. For a deeper dive, check out this report on low-loader trailer industry growth.

Building Our Cities One Machine at a Time

Now, let's shift scenes to a bustling downtown construction site. A new skyscraper is rising, and the project calls for a 100-ton excavator to dig the foundation. Getting this beast into the heart of a city is a major operation. It’s too heavy and slow to move on its own, and its sheer weight could pulverize city streets.

Enter a multi-axle low loader. It's been chosen specifically for its ability to spread that immense weight across enough axles to meet strict road regulations. The move is scheduled for the dead of night to avoid snarling traffic. As the driver skillfully navigates the tight urban grid, the low deck ensures the excavator’s tall cab slips neatly under traffic lights and overpasses.

In this scenario, the low loader isn't just a delivery truck; it's an integral piece of the project's success. It guarantees that essential, high-value machinery shows up exactly when it's needed, keeping the entire construction schedule on track.

This is a masterclass in how low loaders solve the twin problems of concentrated weight and tight site access.

Feeding the Nation with Modern Agriculture

Finally, let’s head out to the heartland. It's just before harvest season, and a brand-new combine harvester—a machine that's both incredibly heavy and exceptionally wide—needs to be delivered to a vast farm. The farmer’s entire year of work hinges on this one piece of equipment arriving on time and in perfect shape.

The harvester is driven onto a Removable Gooseneck (RGN) low loader, a trailer that can lower its deck all the way to the ground, creating a simple drive-on ramp. The journey will take it down major highways before turning onto dusty, unpaved farm roads. Here, the low loader’s stability is critical, protecting the harvester's complex and expensive components from being rattled apart.

This story shows how these trailers tackle the dual challenges of equipment stability and last-mile delivery to remote, rural locations. In an industry where timing is absolutely everything, that kind of reliability isn't just a bonus—it's essential.

Low Loader Applications by Industry

While the examples above give you a good picture, low loaders are the unsung heroes in many more sectors. Each industry presents a unique set of cargo and logistical puzzles. This table breaks down how a few key sectors rely on these specialized vehicles.

| Industry | Common Cargo | Key Logistical Challenge |

|---|---|---|

| Construction | Excavators, bulldozers, cranes, paving machines | Navigating dense urban areas, managing extreme weight on city roads, and coordinating just-in-time delivery to active job sites. |

| Energy & Renewables | Wind turbine blades, transformers, nacelles, generators | Transporting components of extreme length or weight to remote, often difficult-to-access locations like wind or solar farms. |

| Agriculture | Combine harvesters, large tractors, irrigation equipment | Moving wide, heavy machinery over a mix of public highways and unpaved rural roads, often on a tight seasonal schedule. |

| Mining | Haul trucks, massive shovels, crushers, screening plants | Transporting colossal, ultra-heavy equipment into and out of rugged mining sites with poor road infrastructure. |

| Manufacturing | Factory machinery, industrial presses, oversized tanks | Handling delicate, high-value equipment that requires a smooth, stable ride and precise loading/unloading procedures. |

Ultimately, whether it's a skyscraper, a wind farm, or a harvest, the story is the same: progress often arrives on the back of a low loader. These trucks are purpose-built to overcome the physical barriers that would otherwise stop major projects in their tracks.

Getting the Green Light: Permits and Safety Regulations

When it comes to low loader transport, compliance isn't just a suggestion; it's the foundation of a safe, successful haul. Moving oversized machinery is far more complex than just loading it and hitting the road. It demands a meticulous approach to regulations to protect your cargo, the public, and your project timeline from costly delays or accidents.

Think of it as ground-based air traffic control. An oversized load requires a carefully plotted and pre-approved journey, much like a plane needs a flight plan. Skipping this step isn't just risking a fine; it can lead to catastrophic accidents, damaged infrastructure, and significant legal liabilities.

The Paperwork That Paves the Way: Abnormal Load Permits

If your cargo exceeds standard legal limits for weight, width, length, or height, it's classified as an Abnormal Indivisible Load (AIL). Moving an AIL requires specific permits from every state, county, and sometimes even city authority along the route.

These permits are a critical part of the process. Officials review the proposed route to ensure it's viable and safe for a vehicle of that size and weight. It’s a nationwide system designed to prevent oversized loads from causing chaos on the road network.

A permit is more than just permission. It’s a signed agreement that lays out the exact rules for your move—the approved roads, the specific travel times, and whether you’ll need a safety escort to go with you.

This is the first, non-negotiable step in any professional heavy haulage job.

Why Route Surveys Are Absolutely Critical

Before a permit can even be applied for, a detailed route survey is essential. This is not a simple map check; it's an on-the-ground inspection of the entire path by a transport specialist to identify real-world hazards.

The survey team looks for potential deal-breakers:

- Low Bridges and Overpasses: Is there enough vertical clearance? They measure to be sure.

- Weak Bridges: Can the bridge handle the immense weight of the truck and its cargo?

- Sharp Turns and Tight Corners: Will the rig actually be able to make the turn without getting stuck?

- Roadwork and Other Obstacles: Are there any surprises like construction zones or downed power lines?

This survey provides authorities with the hard data needed to approve the permit confidently. It’s about identifying and solving problems on paper to avoid encountering them with a multi-ton machine. To get a better sense of these challenges, it’s worth understanding the logistics behind hauling oversize loads and how pros tackle them.

The A-Team: The Vital Role of Pilot Cars

Once a load reaches a certain size—with rules varying by state—pilot cars (or escort vehicles) become a legal necessity. These vehicles are not passive followers; they are an active, essential part of the safety operation.

Their job is crucial. The lead car drives ahead to warn oncoming traffic and scout for immediate dangers. The rear car acts as a buffer, alerting drivers approaching from behind and protecting the low loader. They maintain constant radio contact with the truck driver, acting as an extra set of eyes and ears to navigate the journey safely.

For the largest loads, a police escort may be required, particularly for navigating urban centers or when temporary road closures are necessary. This coordinated effort ensures the oversized vehicle moves as a single, predictable unit, safeguarding everyone on the road.

What Really Goes into the Cost of Low Loader Transport?

Getting a quote for low loader transport can be revealing. Two jobs that appear similar can have vastly different price tags. The final cost is a combination of many factors that go far beyond the weight of your cargo and the distance of the journey.

To budget accurately and avoid surprises, you must understand these variables. For instance, moving a standard excavator 100 miles on an open motorway is straightforward. Moving the same machine 50 miles through a dense city with narrow streets and traffic restrictions is a far more complex—and expensive—operation.

It's More Than Just Weight and Miles

While cargo size and trip distance are the starting points for any quote, they are only part of the puzzle. The most significant cost drivers are found in the logistical details of the move.

The route itself has a major impact. A journey through mountainous terrain with steep grades and sharp turns consumes more fuel, demands more from the driver, and takes longer than a straight, flat route. Similarly, navigating a congested city center with its traffic, low bridges, and strict delivery windows adds significant operational costs.

The best way to think about transport pricing isn't just in pounds per mile, but in pounds per challenge. Every obstacle, every regulation, and every special request adds a layer of complexity—and that's what you see in the final quote.

This is why providing your transport partner with complete and accurate information from the start is crucial for receiving a reliable quote.

The Financial Hit from Permits and Escorts

The moment your load is classified as oversized or overweight, a new set of costs comes into play. These are not optional extras; they are legally mandated requirements that directly impact the price.

- Permitting Fees: Each county or state authority the truck passes through charges a fee for an oversized load permit. A multi-state journey means paying for multiple permits.

- Escort Vehicles: If pilot cars are legally required, you are responsible for the cost of the vehicles, their certified drivers, and their time for the entire trip. If the job requires a lead and a trail car, the expense doubles.

- Out-of-Hours Travel: Many permits restrict travel to specific times, such as late at night or on weekends, to minimize traffic disruption. This often results in overtime pay rates for the driver and escort crews.

These regulatory costs can accumulate quickly and often constitute a significant portion of the total bill.

Equipment and How Soon You Need It

The specific trailer required for the job also influences the price. A standard flatbed is less expensive to operate than a specialized Removable Gooseneck (RGN) or a multi-axle trailer designed for extreme weight. The more specialized the equipment, the higher the operational cost.

Finally, urgency is a key factor. A last-minute booking that requires the carrier to reschedule other jobs and expedite permits will almost always be more expensive than a well-planned move. Providing your transport partner with ample notice is one of the most effective ways to manage costs without compromising on safety or service quality.

How to Select a Reliable Transport Partner

Choosing the right partner for your low loader transport is one of the most important decisions you will make. While a low quote may be tempting, the potential consequences—damaged equipment, missed deadlines, and legal issues—are not worth the risk. Selecting a partner is about entrusting a high-value asset to a team with proven expertise, a solid safety record, and transparent processes.

Think of it like hiring a specialized surgeon. You wouldn't choose based on price alone; you'd evaluate their experience, success rates, and credentials. The same principle applies here. A professional transport company will have no problem providing clear proof of their capabilities.

Vetting Potential Partners

Before committing, it's essential to investigate a company's background and operational procedures. A trustworthy partner will be transparent and ready to answer your questions. Start by asking for evidence that they have handled loads similar to yours.

A company with experience moving a 100-ton excavator through a dense urban environment possesses a different skill set than one that primarily transports standard farm equipment. Their response will reveal their confidence and familiarity with the specific challenges your cargo presents.

A trustworthy transport provider sees themselves as a partner in your success, not just another vendor. Their focus will be on clear communication, detailed planning, and figuring out potential risks from the very first phone call.

This collaborative approach is often the best sign of a company’s professionalism and commitment to getting the job done safely and successfully.

The Essential Vetting Checklist

Use this checklist to systematically evaluate and compare potential providers. A vague proposal is a major red flag—insist on specific details for each point.

- Ask for Relevant Case Studies: Request concrete examples of similar projects they've handled. This shows you what they can do in the real world, not just what they claim on their website.

- Verify Their Safety Record: Don't be shy about asking for their safety ratings and incident history. A clean record speaks volumes about their discipline and attention to detail.

- Confirm Their Permitting Expertise: Find out exactly how they manage route surveys and get the necessary permits across different states or territories. A seasoned team will have this process down to a science.

- Review Their Insurance Coverage: Don't just ask if they're insured; dig into the details. A company’s insurance coverage is a key indicator of their reliability, so it's wise to understand the essential insurance policies for freight forwarders.

In the end, you're looking for a partner who offers more than just a truck and a driver. You're looking for confidence and peace of mind. Taking the time to properly vet your options is the best way to ensure your valuable assets are in the safest hands possible.

Answering Your Low Loader Questions

When you're planning a big move, questions are bound to come up. Getting clear answers on the specifics of low loader transport is key to keeping your project on time and on budget. Think of it as creating a solid blueprint before the first move is made.

Clarifying these details upfront helps prevent surprises and ensures your entire team, from project manager to driver, is aligned on expectations. Here are answers to some of the most common questions.

What's the Heaviest Load a Low Loader Can Handle?

This depends entirely on the trailer's design and the number of axles. A standard low loader might handle 20 to 40 tons, while highly specialized, multi-axle trailers are engineered to move loads weighing hundreds of tons.

However, the practical limit is determined by road regulations. Governments impose strict per-axle weight limits to protect infrastructure like roads and bridges.

If a load tips the scales beyond the standard legal limits, it's officially classified as an "abnormal load." This triggers a whole different process, requiring special permits that map out the exact route, dictate travel times, and often mandate escorts to keep everyone safe.

This isn't just red tape; it's a crucial step to prevent damage to bridges and road surfaces.

How Do I Get My Equipment Ready for the Move?

Properly preparing your machinery is a critical step for a smooth transport process. First, clean the equipment thoroughly so the transport crew can conduct a proper inspection upon arrival. It is also vital to secure or remove any loose parts, attachments, or personal items from the cab.

Next, provide the transport company with the exact, verified dimensions and weight of your machine. If the equipment is driveable, ensure it is in good working order with sufficient fuel for loading and unloading. Finally, inform your provider of any specific handling requirements or delicate components to prevent accidental damage.

Do I Always Need an Escort Vehicle for an Oversized Load?

Not necessarily. Escort vehicles, or pilot cars, are only legally required when a load exceeds specific dimensional thresholds for height, width, length, or weight.

The challenge is that these regulations vary significantly from one state to another, and sometimes even between local jurisdictions.

- Public Safety: Their main job is to give other drivers a clear warning about the large load ahead.

- A Second Set of Eyes: They help the truck driver navigate tricky spots like tight corners, low bridges, or other hazards.

- Official Liaison: Escort drivers often coordinate with police or traffic authorities when temporary roadblocks are needed.

Your transport partner will determine the exact legal requirements during the route planning and permitting phase, ensuring your shipment is fully compliant from start to finish.

At We Will Transport It, we handle every single detail of the heavy haulage journey, from pulling permits to the final delivery. If you have valuable equipment that needs moving, you can count on our seasoned team to get it there safely and on time. You can learn more about our specialized transport solutions by visiting us at https://www.wewilltransportit.com.