When you're sizing up a lowboy for a heavy haul, you're looking at a few key numbers that make all the difference. Generally, a standard lowboy trailer will have a main deck length anywhere from 24 to 29 feet, a width of 8.5 feet (102 inches), and a loaded deck height sitting between 18 and 24 inches.

Getting these dimensions right is the first and most critical step for moving heavy and oversized equipment both safely and legally. This guide provides the actionable insights you need to navigate the transport process successfully.

Your Quick Guide to Lowboy Trailer Dimensions

Before planning a heavy haul, a solid grasp of lowboy trailer dimensions is essential. These trailers are specifically engineered with a low-profile deck, a feature designed to handle cargo that would be too tall for a standard flatbed.

The entire design of a lowboy is built around that low deck. We're talking about a deck height of just 18 to 24 inches off the ground, a massive drop from the typical 48 inches you'd find on other trailers. This clearance is what allows you to haul towering equipment and still pass under bridges and power lines without complex rerouting.

While the deck length can vary a bit—usually between 24 and 29 feet for the main "well"—the width is almost always standardized at the 8.5-foot legal limit to stay clear of needing special permits for over-width loads. For a deeper look into the evolving lowboy market, check out the analysis on Verified Market Reports.

This unique structure isn't just for show; it delivers real-world transport advantages:

- Hauling Tall Loads: The low deck is essential for moving excavators, bulldozers, and other heavy machinery that would otherwise violate legal height limits, avoiding costly permits and fines.

- Better Stability: With the cargo sitting low, the trailer has a lower center of gravity. This significantly improves stability, which is a critical safety factor when moving top-heavy equipment.

- Easier Loading: Many lowboys, especially Removable Gooseneck (RGN) types, allow equipment to be driven directly onto the deck. This is a game-changer for safety and efficiency, reducing loading times and risks.

Standard Lowboy Trailer Dimension Ranges

To give you a quick reference, here’s a breakdown of the typical dimension ranges you'll encounter with standard lowboy trailers. Use this as your starting point for matching your cargo to the right trailer.

| Dimension | Common Range | Key Transport Consideration |

|---|---|---|

| Deck Length | 24 ft – 29 ft | This is the usable space for your cargo. Measure the full length of your equipment's base to ensure it fits. |

| Deck Width | 8.5 ft (102 in) | The legal standard width. Cargo wider than this requires over-width permits and potentially escort vehicles. |

| Deck Height | 18 in – 24 in | The loaded height. Add this to your cargo's height to calculate total transport height and plan your route around low bridges. |

| Overall Length | 48 ft – 53 ft | Affects maneuverability and may require specific routing in tight areas or on roads with length restrictions. |

| Load Capacity | 40 – 80 tons | Determined by axle configuration. Always verify your equipment's weight against the trailer's capacity to avoid overloading. |

Ultimately, these specs determine if a lowboy is the right tool for your specific piece of equipment. Always start with the precise weight and dimensions of your cargo, then match it to a trailer that can handle the job safely and legally.

Anatomy of a Lowboy Trailer

To master lowboy dimensions for transport, you need to understand the trailer’s basic anatomy. Every part has a purpose, and together they determine what a lowboy can carry safely. It helps to think of it in three main sections: the gooseneck, the main deck, and the rear axle assembly.

The gooseneck is that arched piece up front that hitches the trailer to the tractor. It’s much more than a simple connector; it often contains hydraulics and is a huge factor in loading efficiency. Understanding its design is the first step in matching a lowboy to a specific haul.

The Gooseneck Connection

Goosenecks come in two main types, and the one you choose has a massive impact on your loading process and safety.

- Fixed Gooseneck: As the name implies, this style is welded to the trailer frame. They are generally lighter and simpler, but the trade-off is that you must load everything from the rear of the trailer, usually with ramps. This can be hazardous and slow, especially with machinery that has low ground clearance or cannot move on its own.

- Removable Gooseneck (RGN): This is the industry standard for heavy equipment hauling. An RGN detaches, letting the front of the trailer drop flat to the ground. This forms a perfect ramp for driving equipment straight onto the deck—a massive plus for hauling things like excavators, pavers, or combines. The ability to drive on makes the entire process faster and significantly safer.

Next is the main deck, or "well." This is the business end where your cargo rides. How it’s built directly impacts the trailer’s capacity and overall height. That low-slung well, maybe with a 24-inch loaded deck height, is exactly what lets you haul a 12-foot-tall piece of machinery under a 14-foot bridge without getting tangled up in permitting nightmares.

Actionable Insight: When booking transport for any wheeled or tracked equipment like a bulldozer, always specify that you need a Removable Gooseneck (RGN) trailer. Making this detail clear from the start prevents major loading delays and ensures the right, safe trailer shows up for the job.

Finally, you have the rear axle assembly, or the rear bridge. This part of the trailer carries the weight at the back. The number of axles dictates the trailer’s legal weight limit. A tandem (2-axle) configuration is standard, but for heavier equipment, you’ll need a tridem (3-axle) or even more complex multi-axle setups to spread the load and comply with road regulations.

Decoding Lowboy Deck Dimensions

The deck, often called the "well," is the heart of a lowboy trailer. Its dimensions directly determine what you can legally and safely haul. To match your cargo to the right trailer, you must start by understanding the deck's usable length, width, and loaded height.

Unlike a standard flatbed, a lowboy’s deck sits incredibly low to the ground. This is its key advantage, making it possible to transport tall equipment without violating federal and state height regulations, which typically cap out between 13.5 to 14.5 feet.

Critical Deck Measurements Explained

When planning a heavy haul, three specific deck dimensions need your full attention. Each one plays a unique role in making sure your load not only fits but travels securely. Getting one wrong can lead to costly delays, steep fines, or an unsafe situation on the road.

- Usable Deck Length: This is the actual flat space in the well where your cargo rests. Most standard lowboy decks offer 24 to 29 feet of usable length. For longer loads, like bridge beams or large pipe sections, you must use an extendable or "stretch" lowboy to ensure proper support.

- Deck Width: The standard legal width is 8.5 feet (102 inches). While many lowboys can be equipped with outriggers to support wider loads, any overhang automatically requires wide-load permits, increasing cost and complexity.

- Loaded Deck Height: This is the distance from the ground to the deck surface after the cargo's weight is applied. It typically sits between 18 and 24 inches, and this incredibly low profile is what gives a lowboy its purpose.

Transport Scenario: Let's say you need to move a 12-foot-tall excavator. If you place it on a lowboy with a 24-inch (2-foot) loaded deck height, the total height of your transport comes to exactly 14 feet. This keeps you compliant with the maximum height limit in most states, saving you the headache and cost of special routing and permitting.

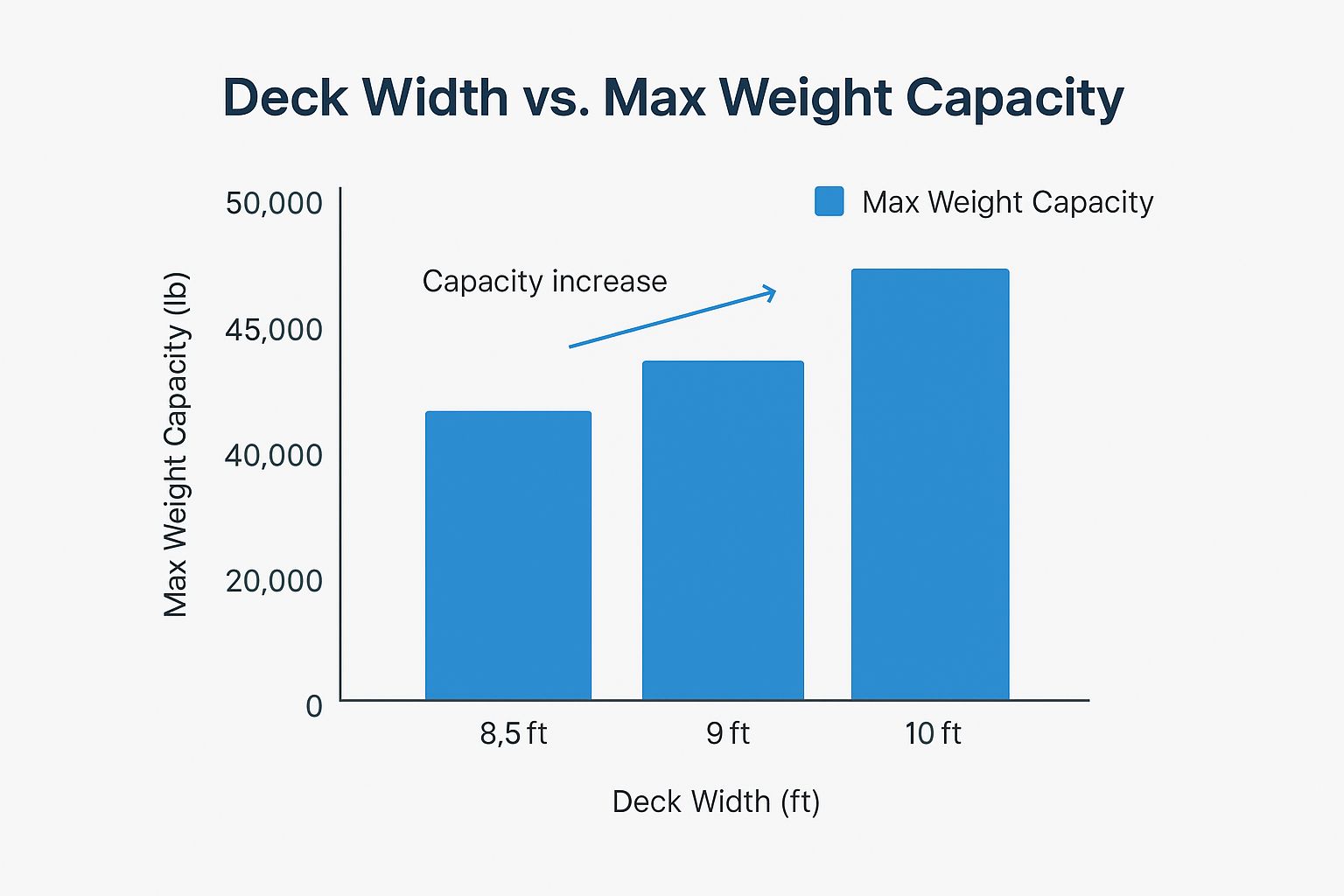

This graphic gives a great visual breakdown of how deck widths relate to overall weight capacities.

As you can see, even a slight increase in width often means a major jump in the trailer's structural strength and how much it can carry.

Lowboy Trailer Deck Specification Table

To help with your planning, I've put together this quick-reference table. It breaks down the deck specs for the most common lowboy configurations you'll encounter. Use this as a checklist when discussing your needs with a transport provider.

| Trailer Type | Typical Deck Length | Standard Deck Width | Loaded Deck Height | Best For |

|---|---|---|---|---|

| Standard Lowboy | 24 ft – 29 ft | 8.5 ft | 18 in – 24 in | Standard construction equipment like excavators. |

| Extendable (Stretch) | 29 ft – 50+ ft | 8.5 ft | 20 in – 26 in | Long, self-supporting loads like beams or blades. |

| Single Drop Deck | 37 ft – 43 ft | 8.5 ft | ~24 in | Taller loads that don't exceed 11.5 feet. |

| Double Drop Deck | ~29 ft | 8.5 ft | 18 in – 22 in | The tallest loads, maximizing vertical clearance. |

This table provides a solid baseline, but always confirm the exact specs of the specific trailer being dispatched for your load before finalizing your transport plan.

Understanding Axle Configurations and Load Capacity

While deck dimensions tell you if your cargo will physically fit, the axle configuration determines if you can legally haul it. The number of axles is directly tied to the trailer's gross vehicle weight rating (GVWR)—the maximum legal weight for the truck, trailer, and cargo combined.

More axles spread the total weight over a larger footprint, which is non-negotiable for protecting roads and bridges from damage. Regulations like the Federal Bridge Gross Weight Formula are built entirely around this principle. A standard tandem-axle lowboy might be fine for a 40,000-pound load, but to move something twice as heavy, you’ll need a more complex setup to keep the weight per axle within legal limits. This is especially true when transporting massive equipment like dozers, where the axle arrangement is just as critical as the deck space.

Common Axle Setups and Their Capacities

Matching your load's weight to the correct axle configuration is a critical step for a successful heavy haul. Each additional axle helps distribute the load more effectively, increasing what you can safely and legally carry.

Here’s a practical rundown of the most common setups:

- Tandem Axle (2 Axles): Your go-to for many standard loads. A tandem setup is typically rated to handle up to 40,000 lbs of cargo.

- Tridem Axle (3 Axles): Adding a third axle boosts capacity to around 60,000 lbs. This is the most common configuration for heavier construction machinery. Our guide on three-axle shipping solutions dives deeper into this option.

- Quad Axle (4 Axles): For serious heavy-haul territory, the four-axle configuration can manage weights up to 80,000 lbs.

- Multi-Axle Setups (5+ Axles): Reserved for superloads. These configurations often use accessories like jeep stingers or flip axles to add length and distribute extreme weights that can easily exceed 100,000 lbs.

It’s Not Just How Many, But How Far Apart

The number of axles is only half the story. Their spacing is also a heavily regulated part of the equation. Spreading the axles farther apart distributes the load over a greater length of road surface, a key variable in the Federal Bridge Formula calculation. It’s all about minimizing stress on any single point of a bridge or road.

Let's put this into practice. To haul a 100,000 lb piece of equipment, a standard tridem setup won't be legal. You would absolutely need a multi-axle configuration—likely with five or more axles spread out, possibly with a spreader bar—to get the weight-per-axle down below the typical 20,000 lb legal limit.

High-strength steel advancements have been a game-changer. Manufacturers can now build lowboys that support maximum gross vehicle weight while reducing the trailer's own tare weight, freeing up more capacity for your cargo.

Understanding the Rules: Navigating Permit Requirements for Oversize Loads

In heavy haul, you're not just moving equipment; you're navigating a complex web of regulations tied to your trailer's dimensions. If your cargo pushes beyond standard legal limits, you've entered the world of oversize or overweight permitting—skipping this step leads to hefty fines, project delays, and serious safety risks.

An "oversize" load is any shipment that exceeds the legal limits for width, height, length, or weight. While rules differ by state, federal guidelines set the foundation for transport, especially across state lines.

In the U.S., the Federal Bridge Gross Weight Formula is a key regulation. The standard legal width is 8.5 feet, and the maximum legal height is usually between 13.5 and 14 feet, depending on the state. The crucial weight limit on most interstate highways is 80,000 lbs gross vehicle weight, which is why multi-axle trailers are essential for spreading the load.

When Do You Need a Permit?

Knowing when to start the paperwork is the first step in planning a haul. If your loaded trailer crosses any of these common legal thresholds, a permit is required.

- Width: Anything over 8.5 feet (102 inches).

- Height: Anything over 13.5 feet (some western states allow up to 14.5 feet).

- Length: Varies by state, but loads on trailers longer than 53 feet frequently trigger permits.

- Weight: Any gross vehicle weight (GVW) over 80,000 lbs.

Actionable Tip: Always measure your cargo's absolute widest, tallest, and longest points. A machine might seem to fit on the deck, but a protruding arm or exhaust stack can easily push your load into oversize territory, requiring permits you didn't plan for.

The Permit Process: A Real-World Example

Let’s make this practical. Imagine you're moving a bulldozer that measures 10 feet wide.

Right away, it's an oversize load because it's wider than the 8.5-foot legal limit. This means you need a permit for every state the dozer will pass through. The process starts by submitting an application with precise details: cargo dimensions, final loaded dimensions, total weight, and a detailed route plan.

Each state's Department of Transportation (DOT) will review your application. If approved, they'll issue a permit that often comes with restrictions, like limiting travel to daylight hours or requiring pilot cars to escort the shipment. For more details, check out our guide on oversize transport permits.

A Closer Look at Specialized Lowboy Trailer Types

Standard lowboys handle most heavy hauling, but some jobs require a more specialized tool. For cargo that’s exceptionally long, wide, or heavy, these advanced lowboy configurations are engineered to handle the most demanding hauls safely and legally.

Knowing about these specialized trailers can open up new possibilities for complex transport projects.

Extendable Stretch Lowboys

When your cargo is longer than the standard 29-foot well, the extendable, or "stretch," lowboy is the solution. These trailers have a telescoping deck that can be pulled out to accommodate unusually long loads.

This feature is a game-changer for moving items that can't be broken down. A stretch RGN, for instance, can often extend its deck from a standard length to over 50 feet, with some models reaching 80 feet or more.

Practical Use Case: Transporting a 60-foot wind turbine blade is impossible on a standard lowboy. An extendable trailer stretches to provide full support along the blade's entire length, properly distributing the weight and making the move safe and legal.

Hydraulic Widening Decks

For equipment wider than the standard 8.5-foot limit, a trailer with a hydraulic widening deck is an excellent solution. Rather than relying on temporary outriggers, these trailers can physically expand their deck width, often up to 12 feet or more, with the push of a button.

This creates a solid, stable platform that is far safer for equipment with wide tracks or an unusual footprint, providing a significant upgrade in stability over traditional methods. Our guide on oversized equipment transportation has more information on moving large machinery.

Modular and Multi-Axle Units

For massive "superloads," modular lowboys are the pinnacle of heavy-haul technology. Think of them as complex, configurable systems. By adding deck sections, dollies, and multiple axle groups, these units can be built to handle loads far exceeding 200,000 lbs.

The principle is based on extreme weight distribution. Spreading the load across dozens of tires is the only way to meet strict per-axle weight limits for roads and bridges, making these colossal moves possible.

A Global Perspective on Lowboy Trailer Dimensions

When moving heavy equipment internationally, it's critical to understand that the lowboy trailer dimensions you're used to in one country don't necessarily apply elsewhere. Regulations are shaped by local infrastructure—road widths, bridge capacities, and even the turning radius of ancient city streets.

For example, what works in North America often won't fly in Europe. North American lowboys are designed for long, straight hauls on massive highway systems. European logistics often involve navigating older, tighter roadways. This reality forces engineers to use trailers with more axles and advanced steering systems to manage sharp turns and comply with strict per-axle weight limits.

How Regional Standards Shape Transport Logistics

The legal design of a lowboy trailer changes dramatically from one continent to the next. These differences impact every step of transport, from manufacturing to routing. Knowing the key regional variations is the first step in sidestepping major operational headaches.

-

North America: The largest market, where standardization is key. The expansive highway network is built for long-haul transport. A standard width of 8.5 feet is common, and deck heights usually need to stay under 24 inches to avoid oversize permits.

-

Europe: Densely populated cities and stricter bridge weight limits demand trailers with multi-axle setups and enhanced maneuverability to spread the load effectively.

-

Asia Pacific: A rapidly growing market fueled by massive infrastructure projects. Regulations can be inconsistent from one country to another, requiring deep local knowledge.

While North America's market size is driven by its standardized highway system, Europe has adapted with more versatile designs like modular trailers. The Asia Pacific region shows enormous potential, but navigating the patchwork of regulations requires careful planning. For a deeper dive into these market trends, check out this lowboy trailer market report.

Actionable Insight: Before booking an international shipment, your first call should be to a logistics partner in the destination country. They have crucial knowledge of local lowboy trailer dimensions, route restrictions, and the permitting process—details that are nearly impossible to manage from thousands of miles away.

Common Questions About Lowboy Trailer Dimensions

When trying to figure out the right trailer for your heavy equipment, many questions come up. Here are clear, straightforward answers to the most common ones.

How Do I Calculate the Total Height of My Load on a Lowboy?

Getting the total height right is critical for a safe and legal haul. The formula is simple: take the loaded deck height of the trailer (usually 18 to 24 inches) and add the height of your cargo at its tallest point.

For example, if you're shipping an excavator that is 11.5 feet tall on a lowboy with a 24-inch (2-foot) deck height, your total transport height is 13.5 feet. This number is your lifeline for route planning, as you must avoid low bridges and stay under the legal height limits, which in most states fall between 13.5 and 14 feet.

What’s the Real Difference Between a Lowboy and a Step-Deck?

Both trailers handle tall loads, but the key difference is deck height. A lowboy features a "well" that sits extremely low, between the gooseneck and the rear axles.

A step-deck trailer (or single-drop) also has two deck levels, but its lower main deck sits higher off the ground than a lowboy's, typically around 36 to 42 inches. For exceptionally tall or top-heavy equipment, the lowboy’s lower center of gravity makes it a much safer and more stable choice.

Here's a practical rule of thumb: If your load is taller than 10 feet, a lowboy is almost always the best and safest option. If your cargo is between 8.5 and 10 feet high, a step-deck could work and might be easier to source.

Can a Standard Lowboy Haul Something Wider Than 8.5 Feet?

Absolutely, but it requires extra steps. The legal width for a standard lowboy is 8.5 feet (102 inches). To carry anything wider, most lowboys are fitted with swing-out brackets called "outriggers" that provide the necessary extra support.

Any cargo that overhangs that 8.5-foot width is officially an "oversize" or "wide load." This means you'll need special permits from every state on the route, and depending on how wide it is, you might also need pilot cars to escort the shipment.

Sorting through the details of lowboy transport can be a headache. That's where a seasoned logistics partner comes in. At We Will Transport It, our job is to manage every single detail—from finding the right trailer for your specific machine to securing every permit needed for the journey. Find out more about how we handle heavy haul shipping by visiting our website at https://www.wewilltransportit.com.