Ever wonder how that package you ordered online shows up at your door, or how fresh produce makes it from a farm halfway across the country to your local grocery store? That’s logistics management in action.

It's the strategic engine running silently behind the scenes of commerce, making sure the right items get to the right place, at the right time, and in the right condition.

The Orchestra Conductor of Commerce

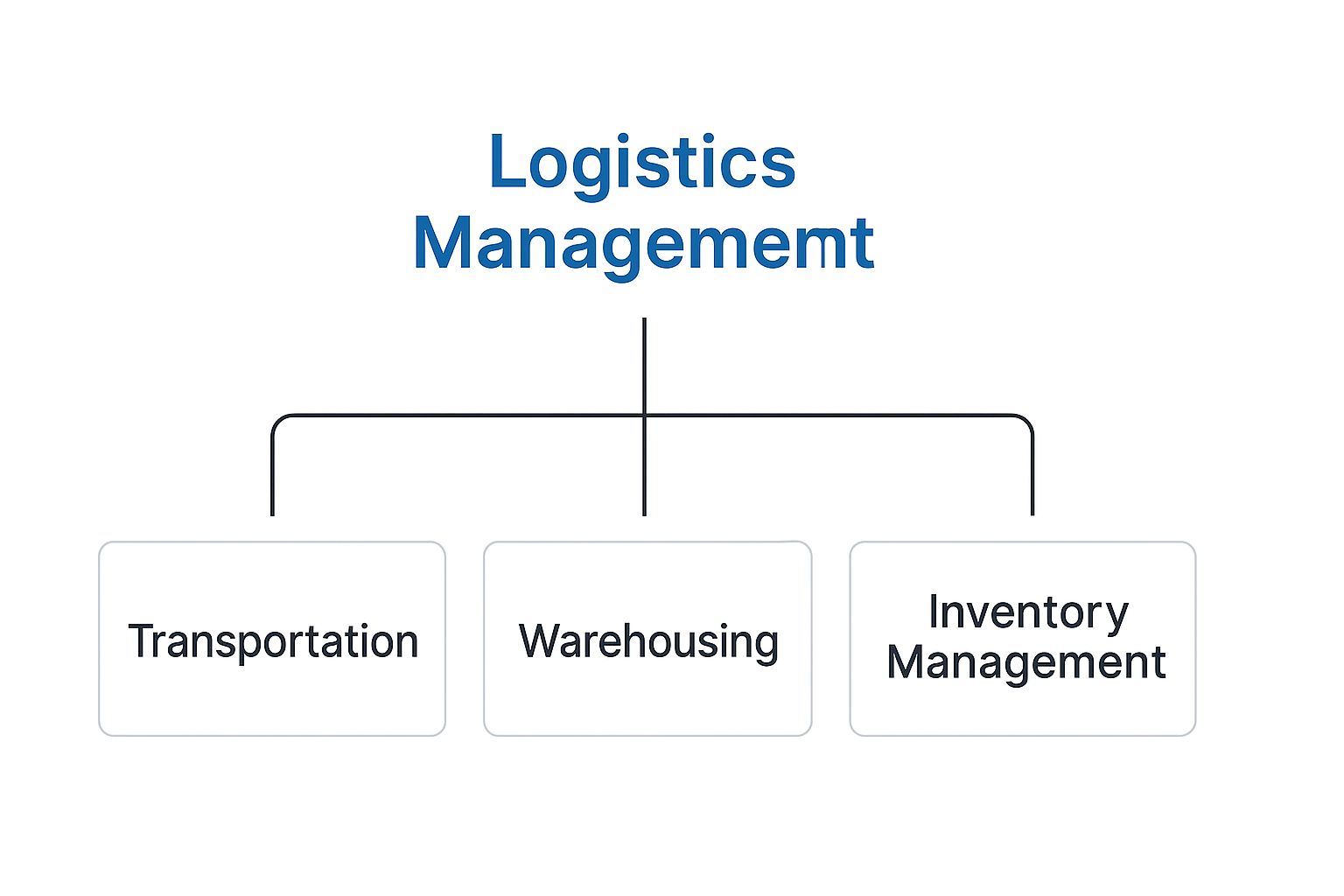

Think of it like this: logistics management is the conductor of a massive, complex orchestra. You have transportation (the percussion), warehousing (the strings), and inventory (the woodwinds). Each section needs to play its part perfectly and in sync with everyone else.

If the trucks are late or the warehouse is a mess, the whole performance falls apart. The conductor’s job is to synchronize every single movement to create a smooth, harmonious flow from the factory floor right to your front door. This is what separates a cost-effective, seamless operation from one that’s just chaotic and expensive.

This whole process is way more than just moving boxes around. It involves some really detailed planning and execution:

- Planning and Procurement: This is the starting line—figuring out where to source the raw materials or finished goods you need.

- Transportation: Choosing the best way to move things, whether that’s by truck, train, ship, or plane.

- Inventory Control: A balancing act of keeping enough stock to meet demand without tying up a bunch of cash in products just sitting on a shelf.

- Warehousing: Storing goods safely and efficiently so they can be easily found and shipped out when an order comes in.

The Core Components of Logistics Management

When you peel back the layers, logistics management really boils down to a few key components that have to work together. This table gives you a quick snapshot of what those are and what they do.

| Component | Primary Function |

|---|---|

| Transportation | Moving goods between locations using trucks, trains, ships, or planes. |

| Warehousing | Storing products safely and organizing them for easy order fulfillment. |

| Inventory Management | Tracking and controlling stock levels to meet demand without overstocking. |

| Packaging & Handling | Ensuring products are protected during transit and storage. |

| Information & Control | Using technology and data to monitor and manage the entire process. |

Each piece is crucial. A breakdown in any one area can cause delays and drive up costs across the entire supply chain.

As you can see, everything is connected. Transportation, warehousing, and inventory are the real workhorses that everything else depends on.

The economic impact here is massive. We're talking about a freight logistics industry that pulls in over USD 1.062 trillion in revenue worldwide. And it's not slowing down, with projections showing a 4.1% global output increase thanks to growing business investment and consumer demand. If you want to dig deeper, you can check out more logistics statistics to get a sense of the scale.

Key Takeaway: Good logistics management isn't just about operations; it's a real strategic advantage. It directly impacts customer happiness, keeps costs in check, and boosts the bottom line. When it’s done right, you get faster deliveries, fewer mistakes, and a much healthier business. It’s the critical link that makes sure you can keep the promises you make to your customers.

The Seven Pillars of an Effective Logistics System

Behind every on-time delivery, there's a well-oiled machine built on seven key pillars working together. Think of it like an orchestra—if one instrument is out of tune, the whole performance suffers. When these functions are strong and perfectly coordinated, you get a seamless supply chain.

Pillar 1: Transportation

This is the one we all see—the trucks on the highway, the ships at sea, the planes in the sky. Transportation is the physical movement of goods and is usually the most visible (and expensive) part of logistics.

The real skill here is picking the right mode of transport. This is a strategic decision that balances cost, speed, and cargo requirements. For example, a high-value sports car requires a secure, specialized carrier for transport, while bulk grain is better suited for cost-effective rail or sea freight.

Actionable Insight: Don’t default to the cheapest or fastest option. Instead, create a checklist for each shipment:

- What is the cargo's value? High-value goods may justify the cost of air freight or specialized, insured carriers.

- What is the delivery deadline? Perishable items or time-sensitive parts demand faster modes like air or expedited trucking.

- What are the cargo's physical needs? Fragile, oversized, or temperature-sensitive items require specific handling and equipment.

Answering these questions ensures you select a transportation mode that protects your bottom line and delivers goods in perfect condition.

Pillar 2: Warehousing

Don't mistake a warehouse for just a big storage shed. Today's warehouses, often called fulfillment or distribution centers, are buzzing hubs of activity. This is where goods are received, sorted, stored, and prepped for the next leg of their trip.

A basic warehouse might just be a place to stack pallets. But a modern fulfillment center is a different beast altogether, using automated robotics and smart software to track every single item. This tech optimizes every square foot of space and makes finding, picking, and packing orders incredibly fast.

Good warehousing means your products are safe, organized, and ready to go at a moment's notice. It slashes the time it takes to get an order out the door, which keeps delays down and customers happy.

Pillar 3: Inventory Management

Inventory management is the art of knowing exactly what you have, where it is, and when you need more. The whole point is to meet customer demand without tying up a ton of cash in stuff that isn't selling or, even worse, running out of popular items.

It's a tightrope walk. Too much inventory means high storage costs and the risk of products becoming obsolete. Too little, and you're looking at lost sales and angry customers. The pros use forecasting software to predict demand and automate reordering, keeping stock levels just right.

Pillar 4: Order Processing and Packaging

The moment a customer clicks "buy," a whole chain of events kicks off. Order processing covers everything from confirming the order details to pulling the items from the warehouse shelves and getting them ready for shipment.

And let's not forget packaging. It’s more than just a box. Proper packaging protects the product from getting banged up in transit—absolutely critical for fragile or high-value items like vehicles, boats, and heavy machinery. It's also your first physical touchpoint with the customer, making it a key part of their overall experience.

Pillar 5: Information Flow

Information is the glue that holds this whole system together. Data has to flow smoothly between every pillar—from the supplier to the warehouse, onto the truck, and all the way to the customer's doorstep.

Think about it: real-time tracking numbers, inventory updates, and delivery notifications are all part of this information flow. Without accurate, timely data, the logistics orchestra falls apart, leading to mistakes, delays, and a whole lot of inefficiency.

Pillar 6: Procurement

Procurement is where it all begins. This is the process of getting the raw materials and goods a business needs to operate. It involves finding the right suppliers, negotiating deals, and purchasing what you need at the best possible quality and price.

A smart procurement strategy ensures you have a reliable supply of goods, which prevents production from grinding to a halt. It lays the foundation for everything that follows.

Pillar 7: The Complete System

These pillars don't work in isolation; they're all deeply connected. A decision in one area, like choosing a new supplier in procurement, will send ripples all the way through to the final delivery.

The logistics world is always changing, whether due to global politics, labor shortages, or shifting markets. For instance, recent transportation capacity indicators show things are tightening up, with a 53.6% capacity index—a noticeable drop from years past. This squeeze makes it even more critical to manage all seven pillars efficiently. To get a better handle on these dynamics, you can check out the insights on the post-peak logistics landscape on Wiima.com.

Ultimately, great logistics management is about orchestrating all these moving parts to build a supply chain that’s tough, cost-effective, and reliable enough to always come through for the customer.

Mastering Your Transportation Strategy

When it comes to logistics, transportation is the engine that pulls everything forward. It's the physical act of getting goods from Point A to Point B, and it's almost always the biggest single expense on the books, often eating up 50% to 60% of a company's entire logistics budget. A smart transportation strategy does more than just move boxes; it sharpens your competitive edge by striking the perfect balance between speed, cost, and reliability.

This isn't just about hiring a truck. It’s a series of make-or-break decisions that ripple through your entire operation, affecting everything from your budget to your customer's happiness. The right choices mean a high-value piece of machinery shows up pristine and a critical delivery lands right on time. The wrong ones can lead to damaged goods, blown deadlines, and lost trust.

Choosing The Right Transportation Mode

The very first decision you have to make is how your cargo will travel. Every option—truck, rail, sea, and air—has its own personality, with a unique blend of strengths and weaknesses. The best fit comes down to what you’re shipping, how much you can spend, and how fast it needs to get there.

Think about it this way: a construction company needing to move a bulldozer across state lines will almost certainly choose a specialized flatbed truck. It’s not the fastest, but it provides door-to-door service and is built to handle heavy, awkward loads. On the flip side, a pharmaceutical company sending life-saving, temperature-sensitive vaccines overseas will pay top dollar for air freight. Speed and climate control are non-negotiable, so the high cost is justified.

Actionable Insight: Create a "transportation decision matrix" to standardize your choices. List your common cargo types down one side and key factors (cost, speed, value, fragility, distance) across the top. Score each transport mode for each cargo type. This simple tool removes guesswork and ensures your team consistently makes the most cost-effective and reliable decision.

To make things clearer, let's break down the trade-offs between the four main ways to move goods.

Comparing Transportation Modes A Practical Guide

Picking the right transport isn't just a detail—it's a strategic choice. This table cuts through the noise to show you how each mode stacks up on the factors that matter most: speed, cost, and capacity.

| Transport Mode | Average Speed | Typical Cost | Capacity | Best For |

|---|---|---|---|---|

| Truck | Moderate | Moderate | Moderate | Flexible, door-to-door delivery for short to medium distances, and specialized loads. |

| Rail | Slow | Low | Very High | Bulk commodities like coal, grain, and chemicals over long land distances. |

| Sea | Very Slow | Very Low | Extremely High | Large volumes of non-perishable goods, vehicles, and heavy equipment for international shipping. |

| Air | Very Fast | Very High | Low | High-value, time-sensitive, or perishable items that require rapid delivery. |

Getting a handle on these differences is what separates good logistics from great logistics. It equips you to build a nimble, cost-effective plan that can handle anything you throw at it. If you're dealing with tricky domestic shipments, digging into options for freight shipping nationwide can open your eyes to specialized carriers you didn't even know existed.

The Power Of Route Optimization

Once you've picked a mode, the next challenge is mapping out the smartest path. Years ago, this was a headache-inducing manual task full of guesswork. Today, modern route optimization software does the heavy lifting for us.

This isn't just a fancy GPS. The technology chews through dozens of variables in real-time, including:

- Traffic Patterns: Steering clear of notorious traffic jams and city-center bottlenecks.

- Fuel Costs: Pinpointing the most fuel-efficient routes to keep costs down.

- Delivery Windows: Making sure shipments arrive within the specific time slots customers demand.

- Vehicle Capacity: Squeezing the most out of every truckload to minimize the number of trips.

Actionable Insight: To get the most from route optimization, don't just "set it and forget it." Regularly audit your routes against actual performance data. Are certain routes consistently slower than projected? Are fuel costs higher than expected? Use this feedback loop to fine-tune the software's parameters and find hidden efficiencies.

Selecting And Vetting Reliable Carriers

At the end of the day, your transportation strategy is only as good as the drivers and companies you trust to execute it. Choosing a carrier isn't something to do on a whim. It demands a bit of detective work to ensure they live up to your standards for safety and professionalism.

When you're sizing up a potential carrier, use this practical checklist:

- Safety Record: Check their safety ratings with agencies like the Department of Transportation (DOT). A clean record is a non-negotiable sign of professionalism.

- Insurance and Licensing: Verify they have sufficient insurance to cover the full value of your cargo. Ensure all licenses and permits are current, especially for specialized or hazardous materials.

- Track Record and References: Ask for references from clients with similar shipping needs. A carrier who consistently delivers on time will be happy to provide them.

- Technology and Communication: A modern carrier should offer real-time tracking and proactive communication. This visibility is crucial for managing your own operations and keeping your customers informed.

Putting in the time to properly vet your partners builds a network you can count on—one that protects your cargo and your reputation. It's a foundational piece of smart logistics that makes sure your plans work just as well on the road as they do on paper.

Shipping Heavy and Oversized Cargo

Moving a vehicle, a boat, or a heavy piece of machinery isn't like shipping a regular package. It’s a whole different ballgame. These are high-value, heavy, and often oversized assets, and they demand a specialized approach to logistics where there’s absolutely no room for error. One small mistake can cause major delays, expensive damage, or steep fines.

The process is far more complex than just loading something onto a truck. Success is all about meticulous planning that starts long before the asset is even touched. You have to think about everything—from the exact type of carrier to the specific route and the mountain of paperwork needed to get it moved legally and safely.

Selecting the Right Specialized Carrier

The first and most critical decision you'll make is picking the right kind of transport and the right carrier to handle it. A standard enclosed trailer just won't cut it for a 40-ton excavator or a 35-foot sailboat. You need specialized equipment built for the task.

Here are the most common options you’ll encounter:

- Flatbed Trailers: These open-deck workhorses are the go-to for heavy equipment. They’re incredibly versatile and can handle items that are wide or tall. You'll also see variations like step-decks and lowboys, which are designed to haul even taller cargo.

- Roll-On/Roll-Off (RORO) Vessels: When you're shipping vehicles or drivable machinery overseas, RORO ships are a fantastic option. The cargo is simply driven onto the ship, which is much safer and more efficient than lifting it with a crane.

- Specialized Haulers: For truly massive loads—the kind that are extremely oversized or overweight—you might need something like a multi-axle trailer or a self-propelled modular transporter (SPMT) designed to handle mind-boggling weights and dimensions.

Actionable Insight: Before you even request a quote, compile a "cargo spec sheet" with the exact length, width, height, and weight of your asset. Include clear photos from all angles. Providing this detailed information upfront allows carriers to give you a more accurate quote and assign the correct equipment from the start, preventing last-minute surcharges or delays. For more details, it's worth learning more about heavy cargo weights and shipping services so you understand the specific requirements for your load.

Navigating Permits and Regulations

Once you’ve lined up a carrier, the next challenge is getting all the necessary permits. Every single state and country has its own set of rules for oversized loads. These regulations control everything from the time of day your cargo can be on the road to the specific highways it's allowed to use.

It's a classic mistake to underestimate how long the permitting process takes. A single cross-country shipment could require dozens of separate state permits, and each one has its own application and lead time.

You'll likely need a stack of key documents, including:

- Oversize/Overweight Permits: These are mandatory if your cargo goes beyond the standard legal dimensions or weight limits.

- Pilot/Escort Vehicle Requirements: Many areas require oversized loads to be accompanied by escort vehicles to keep everyone on the road safe.

- Customs Documentation: For any international shipment, you'll need a bill of lading, a commercial invoice, and other specific forms to get through customs without a hitch.

Preparing and Securing Your Cargo

Getting your asset ready for the journey is crucial to prevent damage. When it comes to vehicles and machinery, this means more than just rolling it onto a trailer. You need to make sure it's prepped for the trip ahead.

Here’s a practical checklist to follow:

- Clean the Equipment: Give your vehicle or machine a thorough wash. This makes it much easier to do a detailed pre-shipment inspection and note any existing scratches or dings.

- Conduct a Full Inspection: Document the item’s current condition with photos and detailed notes. This gives you a clear "before" picture before the carrier takes over.

- Secure Loose Parts: Take off or tie down anything that could come loose during the trip, like antennas on a car or removable attachments on construction equipment.

- Manage Fluids: Drain fuel down to about a quarter tank. You should also check for any fluid leaks that could become a problem on the road.

While the carrier is responsible for properly securing the load, your prep work makes their job easier and the whole process safer. They'll use heavy-duty chains, straps, and chocks to make sure the cargo doesn't move an inch. This careful process is what protects your valuable asset from the bumps and vibrations of a long haul, ensuring it shows up in the same condition it left.

How Technology Is Changing The Game In Logistics

Technology isn't just a sidekick in logistics anymore; it’s the brain of the entire operation. It delivers the visibility, speed, and smarts needed to manage the intricate dance of moving goods across the country and around the world. For any business that wants to keep up with customer demands and stay competitive, getting on board with these advancements is no longer optional.

This isn’t just about upgrading old systems—it’s a total overhaul of how logistics works. Automation and new digital tools are fundamentally reshaping the industry. The global logistics automation market is already worth nearly $88 billion, and experts predict it will explode to $213 billion in the near future, growing at a rapid 13.4% each year.

The Central Nervous System: Transportation Management Systems

At the heart of all this tech is the Transportation Management System (TMS). The best way to think of a TMS is as the central nervous system for your fleet and all your shipments. It hooks every part of your transport network together, giving you one single dashboard to handle everything from picking carriers and planning routes to managing freight bills and tracking shipments in real time.

Forget about juggling a dozen spreadsheets and making endless phone calls. A TMS automates all those headaches. This frees up managers to optimize routes to slash fuel costs, combine shipments to get more trucks off the road, and give customers pinpoint-accurate delivery updates. For anyone planning a complex move, using a TMS to get a free shipping quote can deliver a clear, data-backed cost in just a few minutes.

Seeing Everything With IoT and Telematics

One of the biggest game-changers has been the rise of the Internet of Things (IoT). Tiny, powerful sensors and telematics devices are now attached to just about everything—shipping containers, pallets, and even the trucks themselves. These gadgets are constantly beaming out data on their location, their condition, and their surroundings.

Actionable Insight: Use IoT data to improve more than just real-time tracking. Analyze historical data to identify bottlenecks in your supply chain. For instance, if you see that trucks are consistently idle for hours at a specific warehouse, you can work with that facility to streamline their loading/unloading process, saving significant time and money across all future shipments.

Artificial Intelligence and Seeing The Future

Artificial intelligence (AI) is adding a whole new layer of predictive power to the mix. AI algorithms can crunch massive amounts of data—from past shipping records and weather forecasts to real-time traffic and market trends—to make surprisingly accurate forecasts.

This has a huge ripple effect across the board:

- Demand Forecasting: AI can predict what customers will want and when, helping companies avoid stockouts or over-ordering.

- Predictive Maintenance: By listening to a truck's performance data, AI can flag a potential breakdown before it happens, letting you schedule maintenance instead of dealing with a costly roadside delay.

- Smarter Routes: AI is always learning, constantly finding better and more efficient shipping routes that a human planner might overlook.

Companies are even using this tech to test out wild new ideas. For example, some are already experimenting with drone delivery in fast-food logistics, showing how automation is changing even the final step of getting a product to a customer's door. When all these technologies work together, logistics becomes smarter, faster, and more focused on the customer than ever before.

Common Logistics Questions Answered

Even after getting the basics down, you’ll probably find a few nagging questions pop up when you start digging into the world of logistics management. Let’s clear up some of the most common points of confusion with straightforward answers that give you a much deeper feel for how it all works.

What Is The Difference Between Logistics And Supply Chain Management?

This is a classic, and for good reason—the two are constantly tangled together. The easiest way to separate them in your mind is to remember that logistics is one very important part of the bigger supply chain.

Think of the supply chain as an entire professional football team's operation. It covers everything from scouting and drafting new talent (sourcing materials) and running training camps (manufacturing) all the way to executing the game plan on Sunday and celebrating a win (sales and customer support).

So where does logistics fit in? Logistics is the team's travel coordinator and equipment manager, all rolled into one. It’s the laser-focused job of getting the players (your products) and all their gear to the stadium (the customer) on time and in perfect shape for the game. It’s a make-or-break role, but it serves the team's much larger strategy.

Key Takeaway: Supply chain management is the whole playbook—planning, sourcing, making, and selling. Logistics is the on-the-ground execution of moving, storing, and delivering everything within that playbook.

What Exactly Is Reverse Logistics?

Most of us picture logistics as a one-way street: factory to front door. But what happens when things need to go the other way? That's reverse logistics—the process of managing everything flowing from the customer back to the business.

And it’s not just about handling a t-shirt that didn’t fit. Reverse logistics is a surprisingly broad field that’s vital for keeping customers happy and running a sustainable business.

- Product Returns: The most obvious one. This is managing items customers send back for a refund or a swap.

- Repairs and Maintenance: Bringing a piece of heavy equipment or a company vehicle back to the shop for service or a complete overhaul.

- Recycling and Disposal: Collecting old products or packaging to be recycled or thrown away properly.

- Asset Recovery: This could mean pulling unsold seasonal items from retail shelves or getting leased equipment back at the end of a contract.

A well-oiled reverse logistics system can squeeze a ton of value out of returned items, cut down on waste, and build serious customer loyalty by making returns a breeze. It’s a part of the plan you can’t afford to ignore.

How Can I Start A Career In Logistics?

The logistics industry is a giant, and it’s always hungry for sharp, capable people. The great news is there are tons of ways to get your foot in the door, whether you're fresh out of school or switching careers.

One of the best entry points is to jump right into an operational role. Getting a job as a warehouse associate, a dispatcher, or a freight broker throws you right into the middle of the action. You learn the real, hands-on challenges of moving things from point A to point B, giving you a rock-solid foundation for whatever you do next.

From there, you can start to specialize. Maybe you’ll get certified in supply chain management (like a CSCP) or zero in on a niche like transportation planning or inventory forecasting. As you rack up experience, you can climb into management, overseeing bigger and bigger pieces of the puzzle. The key is to start where the work actually happens.

What Is The Most Important Part Of Logistics?

This is like asking a chef what the most important ingredient is—everything is connected. But if you pressed most experts, they’d probably point to transportation. It's almost always the single biggest line item in a logistics budget, and it's the part of the process your customer sees firsthand.

Just think about it. If the truck doesn’t show up, nothing else matters. You can have the most perfectly organized warehouse and a flawless inventory count, but it means nothing if you can't actually get the product to the customer safely and on time. Delays, damages, and sky-high shipping fees hit your customer satisfaction and your profit margins directly. Because transportation stitches every other stage together and is so tied to the customer experience, getting it right is often the secret to winning the whole game.

When it comes to the nitty-gritty of transportation, especially for big-ticket items like vehicles, boats, and heavy equipment, you need an expert in your corner. We Will Transport It brings over a decade of experience to the table, shipping assets nationwide and internationally with the care they deserve. Get your custom, no-stress shipping quote today.