If you’ve ever seen a road crew laying down a fresh layer of gravel, you’ve probably seen a belly dump truck in action. This isn't your standard dump truck; it’s a highly specialized piece of equipment designed for a specific transport task: placing materials like gravel, sand, and asphalt with incredible precision.

Its bottom-unloading design allows operators to spread aggregates in a long, even line—a technique called windrowing—which is a critical and time-saving process for road construction and large-scale agricultural jobs.

What Exactly Is a Belly Dump Truck?

Think of a giant grain hopper on a farm, which releases its contents from a bottom gate in a controlled flow. A belly dump truck operates on the same principle, but on a much larger, more mobile scale designed for heavy transport.

Unlike a typical end dump truck that simply piles material in one heap, a belly dump is engineered to spread material efficiently over a long distance. This unique transport capability makes it the go-to choice for jobs where precise, linear material placement is a requirement.

At its core, the vehicle is a classic tractor-and-trailer setup. The real innovation is in the trailer, which is essentially a massive, V-shaped bin with a long, controlled gate running along the bottom.

Core Components Working Together

The entire system's efficiency relies on three main parts acting in perfect harmony:

- The Tractor: This provides the power. It’s the truck cab and engine that hauls the trailer and its heavy payload to the job site.

- The Trailer: This is the operational center. The V-shaped hopper is specifically engineered to carry tons of material while maintaining a low center of gravity, making it far more stable and safer on the road and on-site than other dump trucks.

- The Clamshell Gate: This is the key to its unique function. Running along the bottom of the trailer, this gate is powered by hydraulic or pneumatic systems, giving the driver precise control over the unloading process.

The critical operational advantage is that the driver can open the clamshell gate while the truck is moving. This action lays down a continuous, even row of material called a "windrow." For transport and construction logistics, this windrow is essential as it provides a consistent bed of material for graders and pavers, eliminating extra steps and machinery.

Once you understand how these components interact, it's clear that a belly dump is a strategic tool engineered for controlled, linear distribution. This design saves significant time and labor on site, setting the stage for the next phase of construction.

A Look Inside the Belly Dump Truck: Design and Key Features

The belly dump truck is a purpose-built machine where every design element is intentional, optimized over years to deliver stability, durability, and precise control over its payload. For transport professionals, understanding these features is key to leveraging the truck's full potential in situations where other vehicles would fail.

At the heart of its transport functionality is the clamshell gate system. This is a long, hinged gate running the entire length of the trailer's belly. Powered by robust pneumatic or hydraulic systems, an experienced operator can open and close these gates with precision down to the inch.

This level of control makes the signature "windrowing" technique possible. By opening the gates while driving, the truck lays down a perfectly straight and even line of material. For road crews, this is a massive time-saver. It often eliminates the need for separate equipment to spread out clumpy piles of aggregate, directly reducing operational costs and project timelines.

Engineered for Stability and Strength

The trailer’s iconic V-shaped hopper is a key engineering feature. It naturally funnels all material toward the clamshell gate, ensuring a smooth and complete discharge. More importantly, it positions the load's weight low to the ground.

By maintaining a low center of gravity, a belly dump truck is fundamentally more stable than an end dump, which must lift its entire heavy load high into the air to unload. This stability is a significant safety benefit, especially when transporting and operating on the uneven terrain of a construction site.

From a transport perspective, the ability to unload while moving, combined with a lower center of gravity, makes the belly dump truck a safer and more efficient choice for large-scale paving and material-spreading operations.

To transport such heavy loads, these trailers must be incredibly tough. Fleet managers face a critical choice between steel and aluminum construction, each offering distinct transport advantages:

- High-Strength Steel: The workhorse option. It provides superior durability against abrasive materials like rock and asphalt. For the most demanding transport jobs, steel is the reliable choice for longevity.

- Lightweight Aluminum: Choosing aluminum reduces the trailer's tare weight, which means you can legally transport a larger payload per trip. This is an excellent choice for maximizing efficiency with lighter, less abrasive materials where transport volume is the priority.

This careful balance between strength and weight is what makes these trailers profitable and durable. The dump trailer market is projected to grow from USD 11.43 billion in 2025 to over USD 27.35 billion by 2035, with belly dumps holding a solid 20% of that market. You can explore more about the future of dump trailers in this market report from Business Research Insights.

Comparing Belly Dump, Side Dump, and End Dump Trucks

Selecting the right dump truck for a transport job is a critical logistics decision that directly impacts your project's timeline, budget, and safety. While belly dumps, side dumps, and end dumps all transport bulk materials, they are specialized machines. Knowing which to deploy is a key operational skill.

The belly dump truck is the master of linear projects. For transport operations involving road construction, asphalt paving, or laying a base layer, its ability to create a "windrow" is unmatched. By opening its clamshell gates underneath while moving, it lays down a controlled line of material, allowing graders to work immediately and efficiently.

Conversely, the classic end dump truck is designed to create a stockpile. Its bed lifts, and the entire load slides out the back in one pile. This is ideal for transporting materials to a central point, like a quarry or a plant hopper. The major transport risk is its high center of gravity during the dump, making it the most likely of the three to tip over, especially on unlevel ground.

Choosing The Right Tool For The Job

The side dump truck solves specific logistical challenges. It dumps its entire load to the left or right side, making it a game-changer in tight job sites or for backfilling a long trench. They are faster and more stable than end dumps but lack the precise, even spread of a belly dump.

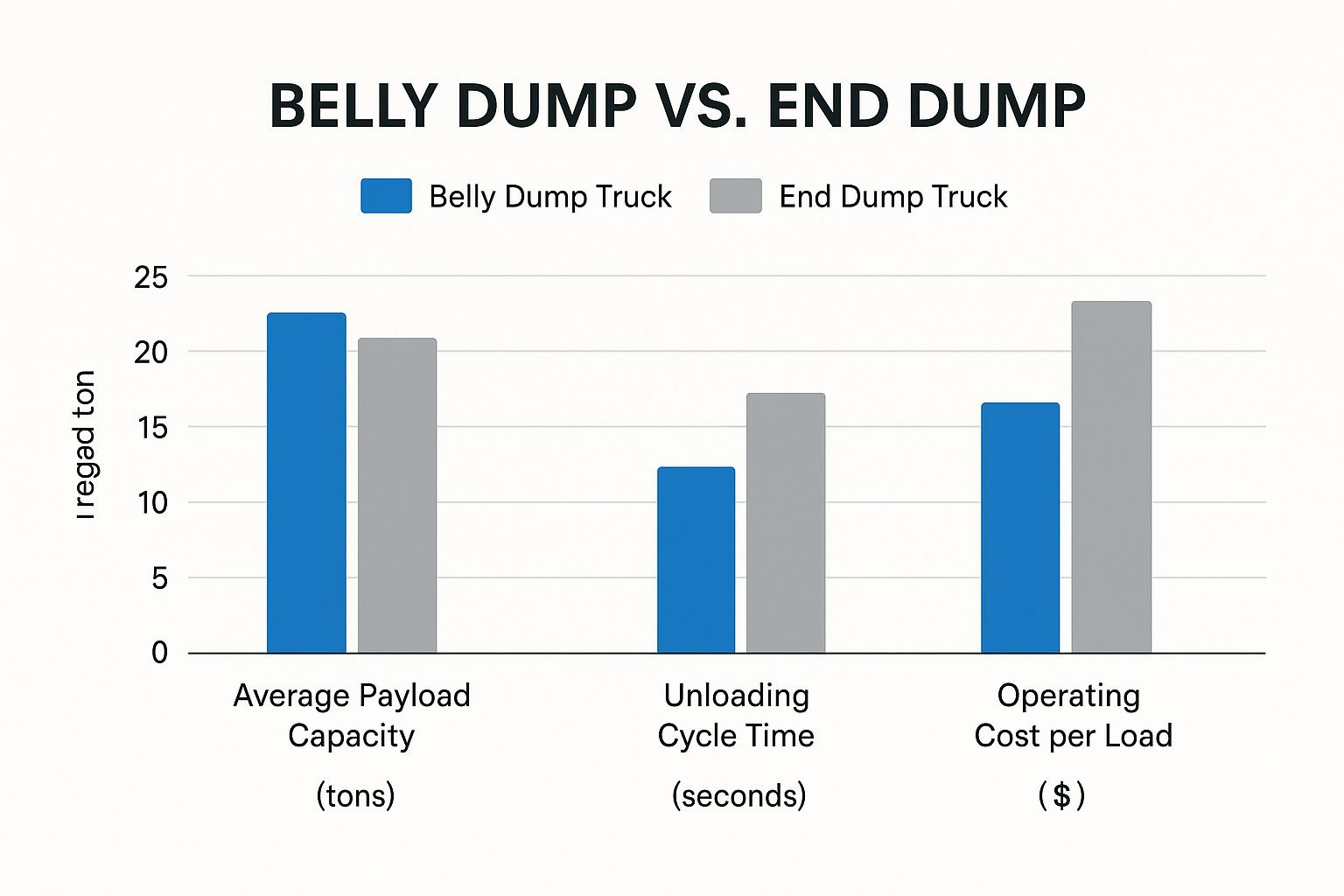

Consider how key transport metrics compare, especially between the specialized belly dump and the common end dump.

As you can see, while they transport similar loads, the belly dump's lower operating cost can significantly impact profitability on the right type of transport contract.

To make the choice clearer, here is a breakdown of their primary transport applications.

Belly Dump vs End Dump vs Side Dump Comparison

| Feature | Belly Dump Truck | End Dump Truck | Side Dump Truck |

|---|---|---|---|

| Primary Use | Spreading material in long, even lines (windrows) | Piling material in one location; stockpiling | Dumping alongside the truck; backfilling trenches |

| Unloading Method | Bottom-opening gates | Tilting the entire bed upwards from the rear | Tilting the entire tub to the left or right |

| Placement Control | Excellent, precise control over the spread | Poor, creates a single large pile | Good for placement next to the truck |

| Stability | Very high; lowest center of gravity | Low; highest risk of tipping over | High; very stable during dumping |

| Unloading Speed | Slower, as it's a controlled release | Fast, but requires careful positioning | Very fast, often the quickest cycle time |

| Best For | Road construction, asphalt paving, site prep | Quarries, large stockpiles, feeding plants | Tight job sites, road shoulder work, trench filling |

Ultimately, successful transport logistics depends on matching the truck to the task.

Assigning an end dump to lay miles of road base would create excessive work for the grading crew, wasting time and money. Likewise, using a belly dump to build a large stockpile would be inefficient. Understanding these operational differences is crucial for running a profitable transport operation.

Core Applications in Construction and Agriculture

The belly dump truck's unique design provides massive efficiency gains in two primary industries focused on bulk material transport: construction and agriculture. Its ability to place materials in a controlled, linear fashion makes it an indispensable asset for any large-scale project.

In construction, the belly dump is the workhorse of paving and site preparation. Its most critical role is building the foundation for new roads, highways, and parking lots. Before asphalt or concrete can be laid, a uniform aggregate base is required, and this truck delivers it with unparalleled efficiency.

As the operator drives at a steady pace, the clamshell gates release gravel or sand to create a perfect "windrow." This single action can eliminate the need for bulldozers to push around messy piles left by end dumps, saving significant time and labor. The logistics of scheduling these material deliveries are vital; a strong grasp of building materials transportation is essential for keeping a project on schedule and within budget.

From Roadways to Farmlands

The same features that make the belly dump ideal for construction sites also make it invaluable for agricultural transport. Farmers and agribusinesses need to move enormous quantities of commodities like grain, feed, and fertilizer efficiently.

The belly dump trailer is built for this type of high-volume transport. Its low center of gravity provides stability on soft farm ground, and its bottom-release gates make unloading into ground-level hoppers, pits, and augers safe and quick. Unlike a tippy end dump, the belly dump remains firmly planted during discharge.

The ability to unload directly into receiving equipment without extra machinery is a major logistical advantage on the farm. It minimizes handling time, reduces material spillage, and streamlines operations during critical planting and harvest seasons.

Key agricultural transport applications include:

- Grain Transport: Moving harvested crops from field to silo. The controlled flow from the gates prevents overwhelming the receiving auger, reducing downtime.

- Fertilizer Spreading: Hauling bulk fertilizer to a central point for quick loading into field spreaders.

- Feed Delivery: Transporting large loads of animal feed to livestock operations for clean and efficient unloading into storage bins.

Whether on a construction site or a farm, the belly dump truck is a key component of the workflow. Its unique ability to place material precisely where needed has a direct impact on productivity and profitability.

Getting the Job Done Right: Safety and Best Practices

Operating a belly dump truck safely and efficiently requires skill and attention to detail, especially during the unloading process. For drivers and fleet managers, adhering to best practices isn't just about productivity—it's about preventing accidents, minimizing downtime, and protecting your equipment investment.

A thorough pre-trip inspection is the first line of defense against transport delays and safety incidents. With a belly dump, this inspection must go beyond standard truck checks.

The Pre-Trip Inspection: What to Look For

Your daily walk-around is critical. Pay special attention to the components that are unique to a belly dump trailer:

- The Gate Mechanism: Inspect all hydraulic or pneumatic lines for leaks, cracks, or wear. Actuate the gate to ensure it opens and closes smoothly. Any sticking or jerking could indicate a problem with cylinders or linkage that requires immediate maintenance.

- Hydraulic Systems: Check the fluid level and condition. Low or contaminated fluid can lead to system failure during a dump, resulting in an uncontrolled gate and a costly cleanup.

- Tires and Suspension: These low-riding trailers depend on correct tire pressure and a solid suspension for stability. Look for uneven tire wear, which can indicate an alignment issue that compromises handling, especially on rough job sites.

Nailing the Perfect Dump

The key to a belly dump's efficiency is unloading on the move. To do this safely, the driver must maintain a slow, consistent speed—typically just a few miles per hour. This steady motion is what creates a perfect, even windrow, reducing subsequent work for the grading crew.

The secret to a flawless windrow is consistency. Abrupt braking or acceleration will create clumps and gaps, defeating the primary purpose of using a belly dump for the transport job.

Uneven terrain presents the biggest risk. While a belly dump is far more stable than an end dump, it is not immune to tipping. Drivers must be trained to assess the terrain before opening the gates, avoiding steep side slopes that could dangerously shift the truck's center of gravity.

Situational awareness is always paramount. While you don't have the overhead power line concerns of an end dump, it is crucial to be aware of your surroundings. On busy sites, broader safety measures like diesel particulate matter monitoring contribute to a safe environment. When a job involves complex maneuvers with other machinery, coordinating with a spotter for proper rigging and lifting heavy equipment is an essential part of the transport safety plan.

Understanding Transport Logistics and Cost Factors

Running a profitable belly dump truck operation is a lesson in logistics and cost management. The machine's true efficiency is determined by key variables that every owner-operator and fleet manager must monitor daily.

Operating costs include fuel, maintenance, tires, and driver pay. For a belly dump, preventive maintenance on the hydraulic or pneumatic gate systems is non-negotiable. A system failure mid-job means immediate downtime and lost revenue.

Maximizing Profitability Per Trip

The core principle of profitable hauling is payload optimization. Every trip should transport the maximum legal weight possible. Running a truck partially full is inefficient—you incur nearly the same fuel and labor costs for a fraction of the revenue.

Every extra pound of material legally transported directly increases the profit margin. This makes a thorough understanding of local and federal bridge laws and axle weight limits a critical knowledge base for any transport business.

Effective route planning and scheduling are equally important. The movement of materials is deeply connected to overall construction logistics strategies. Knowing the best routes, timing runs to avoid traffic, and coordinating with on-site crews to minimize idle time are actionable steps that significantly reduce operational costs and improve turnaround times.

For fleet managers seeking to optimize their transport processes, a comprehensive guide like the one found at https://www.wewilltransportit.com/preparing-your-heavy-equipment-for-transport/ can provide valuable insights.

Broader Market Influences

Beyond daily operations, the wider economy influences profitability. The entire dump truck market, valued at USD 67.2 billion in 2024, is projected to climb to USD 102.1 billion by 2030, driven by a global boom in infrastructure projects.

This signals strong, sustained demand for the transport services a belly dump truck provides. For fleet owners, this outlook is promising, but it also underscores the need for sharp financial management to maintain a competitive edge.

Got Questions? We’ve Got Answers.

When dealing with specialized transport equipment, questions are common. Here are answers to some of the most frequent inquiries about belly dump trucks to help you plan your next transport project.

How Much Can a Belly Dump Truck Actually Haul?

A standard belly dump truck can typically transport a payload between 22 to 35 tons (44,000 to 70,000 pounds).

The exact legal payload depends on the trailer's length, its construction material (heavier steel vs. lighter aluminum), and most importantly, the specific federal and local axle weight regulations for the transport route.

Can I Use It for Big Rocks or Demo Waste?

No. Belly dump trucks are designed specifically for transporting flowable materials like sand, gravel, and asphalt. Their clamshell gate mechanism is not built to handle large, jagged items such as boulders or demolition concrete.

Attempting to force oversized material through the gates will almost certainly cause severe and costly damage to the unloading system.

For transporting large, irregular materials like boulders or demolition debris, an end dump or side dump truck is the correct choice. Their open-box design can handle these loads without risking damage to the equipment.

Are Belly Dumps Hard to Operate?

Driving the tractor-trailer is standard for any experienced CDL holder. The specialized skill lies in the unloading process.

Achieving a perfectly even windrow by spreading material while moving requires practice and a feel for the equipment. However, their superior stability makes them significantly safer to operate during the dump cycle compared to an end dump, which carries a much higher risk of tipping over.

Whether you need to move a single belly dump or an entire fleet, We Will Transport It handles heavy equipment transport across the nation. Get a free, no-obligation quote and let us take care of the logistics. Find out more at https://www.wewilltransportit.com.