Shipping heavy machinery across borders involves more than standard freight logistics; it's a complex process requiring deep knowledge of transport methods, strict regulations, and strategic planning. A single misstep in the transport chain can lead to expensive delays and damaged assets. This guide provides actionable insights to help you navigate the process, from selecting the right shipping method to preparing your equipment for the long haul.

Laying the Groundwork for a Smooth Export

Before you book a container or arrange inland transport, a solid plan is essential. This foundational stage is about understanding the transport logistics and identifying the expert partners who will move your equipment safely and legally. The global heavy machinery market is projected to reach approximately $290 billion by 2029, driven by global infrastructure projects, which means more equipment on the move than ever before.

Assembling Your Export Team

Attempting to manage international heavy equipment transport solo is a high-risk endeavor. Success hinges on partnering with specialists who understand the unique challenges of moving oversized assets across borders.

Here are the key transport and logistics players you need:

- Freight Forwarders: Your transport project managers. A forwarder specializing in heavy machinery will select the best carrier, book vessel space, and coordinate every leg of the journey, from inland trucking to final delivery.

- Customs Brokers: The legal navigators of international trade. They prepare and submit all required documentation to ensure your equipment clears customs without delays, preventing costly port storage fees.

- Insurance Providers: Your high-value equipment requires specialized cargo insurance. These providers offer policies that protect your financial interests against damage or loss during transit.

Actionable Tip: When vetting freight forwarders, ask for case studies or references for shipments of similar equipment to your target destination. Their experience with specific routes and machinery types is invaluable in preventing your multi-ton excavator from getting stuck at a port for weeks.

The Core Stages of the Export Process

While every shipment is unique, the fundamental transport and logistics process remains consistent. Understanding this framework helps you anticipate next steps and manage the timeline effectively.

Here is a breakdown of the key logistical phases:

| Phase | Key Activities | Primary Goal |

|---|---|---|

| Preparation & Planning | Researching transport options, securing financing, finding a buyer, and selecting your logistics partners. | To establish a viable transport plan and assemble the right team for the job. |

| Documentation & Compliance | Gathering all necessary permits, commercial invoices, and bills of lading required for transport. | To meet all legal requirements of both the exporting and importing countries. |

| Logistics & Transportation | Arranging domestic trucking, securing ocean freight, and ensuring the equipment is properly prepped and secured for transit. | To physically move the equipment from origin to destination safely and efficiently. |

| Customs & Delivery | Clearing customs in the destination country and coordinating final inland transport to the buyer. | To complete the final leg of the journey and ensure the buyer receives the equipment. |

Diving Deeper into the Details

Every export shipment has unique transport requirements. For instance, the customs rules and port capabilities for sending a bulldozer to South Africa differ vastly from shipping an excavator to Germany. Country-specific knowledge is vital.

For a great real-world example, this practical guide on how to export from South Africa offers a fantastic breakdown of the nuances involved in one specific market. Of course, the physical logistics are just as important as the paperwork. Getting the transport strategy right from the start is critical for a successful outcome.

Getting Your Paperwork and Customs in Order

Paperwork is the leading cause of transport delays and budget overruns in heavy equipment exports. A single error—a wrong HS code or a mismatched value—can leave your six-figure machine stranded at a port, accumulating demurrage fees that can cost thousands per day. Think of your documentation as the passport for your equipment; without it, it goes nowhere.

Every document must be consistent. The machine's value, specifications, and origin must align perfectly across all forms. Customs officials are trained to spot discrepancies, which are a primary trigger for time-consuming inspections.

The Must-Have Documents for Any Export

While requirements vary by destination, a core set of documents is non-negotiable for any international shipment.

Here’s the essential trio for transport:

- Commercial Invoice: This is the primary document used by customs to assess duties and taxes. It must contain a detailed description of the equipment (make, model, year, VIN/serial number), its declared value, and information on the buyer and seller.

- Bill of Lading (B/L): This is the master contract for the entire transport leg. It acts as a receipt from the carrier and, most importantly, the document of title. The holder of the original B/L has legal ownership of the cargo at the destination.

- Certificate of Origin (COO): This document verifies the country of manufacture. It is crucial for determining if any trade agreements apply, which can significantly reduce import tariffs for the buyer.

Any inconsistency is a red flag. If your Commercial Invoice lists a 2018 Caterpillar D6 Dozer but the Bill of Lading has a vague "Used Bulldozer," you are inviting a full customs inspection.

Don't Mess Up the Harmonized System Code

One of the most critical details for smooth customs clearance is the Harmonized System (HS) code. This universal product classification code is the exporter's responsibility to assign correctly.

An incorrect HS code is a serious issue. For instance, an excavator falls under HS code 8429.52, while a motor grader is 8429.20. This seemingly minor difference dictates the import duty rate. A wrong code can lead to overpayment of taxes by your buyer or, worse, accusations of fraud if it appears you were attempting to secure a lower duty rate.

We’ve seen exporters use a generic HS code for "construction machinery." This is a major red flag for customs. It almost always triggers a physical inspection, which can easily add weeks and thousands of dollars in port fees to your shipment. Be specific.

A Real-World Paperwork Nightmare (And How to Avoid It)

Consider this common, costly error: You export a used John Deere tractor to Brazil, sold for $50,000, and declare this value on the Commercial Invoice. However, you also include an insurance certificate valuing the tractor at its replacement cost of $75,000.

Brazilian customs will immediately flag this discrepancy. The shipment will be held while they investigate the true value. Your tractor is now stuck, your buyer is frustrated, and daily storage fees are mounting.

The solution is simple: ensure the declared value is identical across every single document submitted.

Remember the domestic leg of the journey. Moving oversized machinery to the port often requires special state-level permissions. Our guide on securing oversize transport permits provides actionable steps for this critical pre-export phase.

Here are a few practical tips to keep your paperwork bulletproof:

- Build a Master Checklist. Create a standardized document checklist for every export to ensure consistency.

- Get a Second Opinion. Have your freight forwarder or customs broker review all documents before submission. Their expertise is your best defense against errors.

- Go Digital and Physical. Keep high-quality digital scans of everything and maintain a physical folder with copies. A backup can save a shipment if an original document is lost in transit.

Choosing the Right International Transport Method

Selecting the correct international shipping method is a critical strategic decision that directly impacts cost, transit time, and the security of your high-value asset. The global heavy machinery transport market is a $10 billion industry in 2024 and is projected to grow to $15 billion by 2033, with North America accounting for roughly 35% of the market share. For more details, explore these heavy equipment shipping statistics.

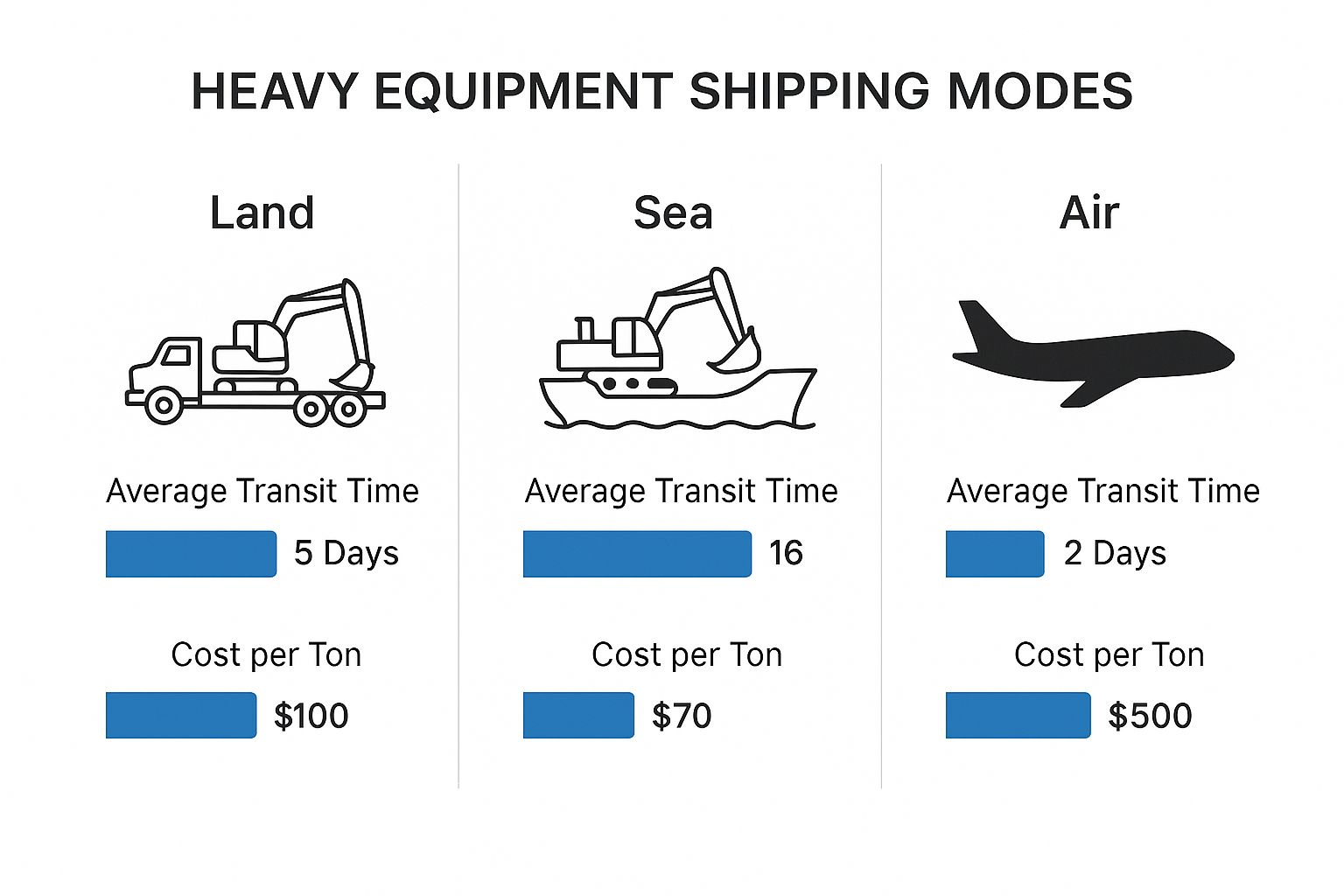

The fundamental trade-off in logistics is always speed versus cost, as illustrated below.

For heavy equipment, sea freight is the most common and cost-effective option for long-distance transport. Air freight is reserved for urgent, high-value parts, not entire machines.

Roll-On/Roll-Off (RoRo) Shipping Explained

For equipment that can be driven or towed—such as bulldozers, excavators, and trucks—Roll-on/Roll-off (RoRo) shipping is the most efficient and cost-effective method. The equipment is simply driven onto a specialized vessel, secured in a garage-like deck, and driven off at the destination port.

The primary advantage of RoRo is its simplicity. It eliminates the need for expensive crane operations for loading and unloading, reducing both costs and the risk of handling damage. However, the equipment is exposed to marine air and accessible to crew and port personnel, which can be a security consideration.

Lift-On/Lift-Off (LoLo) for Static Equipment

For static, non-operational, or oversized equipment like power generators or factory components, Lift-on/Lift-off (LoLo) is the solution. Port cranes lift the cargo from the dock and place it onto the vessel's deck, where it is securely lashed and braced for the ocean voyage. LoLo is highly versatile and can handle extremely heavy and awkwardly shaped cargo. The main downsides are the higher costs associated with crane services and specialized rigging crews.

Container Shipping for Added Security and Flexibility

For high-value or delicate machinery, containerizing provides superior security and protection from the elements. This is typically achieved using specialized containers.

- Flat Rack Containers: These have a base and end walls but no side walls or roof, allowing oversized cargo to be loaded and secured. They are ideal for equipment that is too wide or tall for a standard container.

- Open-Top Containers: These feature standard walls but a removable tarpaulin roof, enabling tall equipment to be loaded from above with a crane.

Actionable Scenario: You need to export a new, high-spec Volvo excavator valued at over $300,000. While RoRo is cheaper, the machine would be accessible during transit. For a high-value asset, paying extra to secure it on a flat rack container places it within the secure container stack, virtually eliminating risks of theft or vandalism. The additional transport cost provides significant peace of mind.

Making the Final Decision

Your choice of transport method depends on three factors: the equipment's mobility and dimensions, your budget, and your risk tolerance. This table offers a clear comparison to guide your decision.

Heavy Equipment Shipping Method Comparison

Deciding between RoRo, LoLo, and container shipping depends entirely on your specific needs. Each method offers a unique balance of cost, security, and equipment compatibility. This table provides a clear, at-a-glance comparison to help you match your machine to the right shipping solution.

| Transport Method | Best For | Cost Factor | Key Advantage |

|---|---|---|---|

| RoRo (Roll-on/Roll-off) | Drivable, wheeled, or tracked equipment (dozers, excavators, trucks) | Low to Medium | Fast and simple loading/unloading; highly cost-effective. |

| LoLo (Lift-on/Lift-off) | Static, non-operational, or extremely large machinery (generators, industrial parts) | Medium to High | Versatility to handle virtually any size, weight, or shape. |

| Container (Flat Rack/Open-Top) | High-value, delicate, or slightly oversized equipment that needs protection | High | Superior security, asset protection, and weather resistance. |

Ultimately, the best course of action is to consult an experienced freight forwarder. They can provide quotes for all viable options and offer insights based on the specific machine, route, and destination port capabilities, ensuring you make a decision that protects both your equipment and your budget.

Preparing Your Equipment for a Long Journey

Proper preparation before your equipment leaves the yard is a critical risk management step that ensures it arrives at its destination ready for work. This process protects your investment from damage, prevents customs delays, and minimizes potential disputes with buyers.

The Critical Deep Clean for Biosecurity

Many countries, especially Australia and New Zealand, enforce strict biosecurity laws to protect their local ecosystems from foreign soil, plant matter, and pests. A machine arriving with residual dirt is guaranteed to be quarantined for mandatory cleaning at the importer's expense. This process can cost thousands of dollars and delay delivery by weeks.

A thorough cleaning is non-negotiable. Your cleaning checklist must include:

- Pressure Washing: Clean the entire exterior, focusing on the undercarriage, tracks or tires, and attachments like buckets or blades. All soil and debris must be removed.

- Engine Bay and Radiator: Degrease and clean the engine compartment and ensure radiator fins are completely clear.

- Cab Interior: Vacuum and wipe down the entire cab, including under seats and in storage compartments, to remove any organic matter.

Safely Decommissioning for Transit

Next, the machine must be made safe for ocean transport. This involves following strict protocols to prevent fires, leaks, or electrical hazards during the voyage.

First, disconnect the battery to prevent accidental startup or electrical shorts. Wrap the disconnected cable ends in electrical tape to avoid contact with the terminals. Next, manage fluid levels. Do not drain all fluids, as this can damage seals, but reduce them significantly. A general rule is to leave no more than a quarter tank of fuel and drain most hydraulic fluids to reduce weight and minimize leak risks.

An often-overlooked but crucial step is protecting sensitive electronics and components from the corrosive saltwater environment. Use heavy-duty plastic sheeting or specialized wraps to cover control panels, electronic displays, and exposed hydraulic fittings to prevent rust and degradation during transit.

Documenting Everything with a Condition Report

Before the equipment leaves your control, create a detailed pre-shipment condition report. This document, supported by photographic evidence, is your essential proof of the machine's state and is vital for any potential insurance claim.

A robust report should include:

- High-Resolution Photos: Take comprehensive photos from all angles. Capture close-ups of the engine, cab, undercarriage, serial number plate, and any pre-existing damage like scratches or dents.

- Record Key Details: Document the machine's make, model, year, serial number, and the current hour meter reading.

- Note Pre-Existing Damage: Honestly list all existing cosmetic and mechanical issues. This transparency protects you from liability for damage that was present before shipping.

This process is a small investment of time that can save you from a significant financial loss. As part of your security protocol, consider implementing cargo theft prevention measures. For more detailed guidance, review our in-depth article on preparing your heavy equipment for transport.

Understanding the True Cost of Exporting

To accurately budget for exporting heavy equipment, you must look beyond the initial ocean freight quote. Many exporters focus solely on the sea voyage cost and underestimate the numerous ancillary charges, leading to eroded profit margins or even losses. The true cost is a sum of all transport, handling, and administrative fees from door to door.

Inland transport from your location to the port is a major expense. In the U.S., this can range from $3 to $8 per mile, depending on the equipment's size, weight, and route. Regional rates also vary, from around $2.95 per mile in the West to $3.76 per mile in the Southeast. You can explore more data on these transport costs to better forecast this expense.

Uncovering the Hidden Port and Customs Fees

Once your equipment arrives at the port, a new layer of fees begins. These costs are often bundled into quotes but are essential to understand, as they can increase your final bill by 20-30%.

Key pre-export charges include:

- Terminal Handling Charges (THC): The port's fee for moving your machine from the delivery truck to the vessel's side, covering labor and equipment like cranes.

- Wharfage Fees: A fee levied by the port authority for using its infrastructure and docks.

- Customs Brokerage Fees: The fee for a licensed broker to prepare and file your export documentation. This is a vital service for avoiding costly delays.

Additionally, you must clarify who is responsible for import duties and taxes at the destination. Clearly define this in your sales contract to avoid disputes with your buyer.

A Real-World Example Shipping an Excavator

Let's illustrate with a practical example: transporting a 45,000-pound excavator from Dallas, Texas, to a buyer in Germany via the Port of Bremerhaven.

The cost journey begins with inland freight from Dallas to the Port of Houston. At the port, you will incur THC and wharfage fees. Next is the primary ocean freight cost for a RoRo shipment. Upon arrival in Bremerhaven, the buyer will face local port charges, potential import duties, and the cost of final inland transport. Each stage adds a distinct layer to the total cost.

A common mistake is to select a carrier based solely on the lowest ocean freight rate. This rate may be offset by higher port fees or a less efficient shipping route. Always demand a fully itemized, door-to-door quote to see the complete financial picture.

Why Carrier Liability Is Not Insurance

A critical and often misunderstood aspect of budgeting is risk management. Many shippers mistakenly believe that the carrier's liability coverage is sufficient protection.

It is not.

Carrier liability is minimal, designed to protect the carrier, and may only pay out a few hundred dollars for a machine worth hundreds of thousands. Relying on it is a significant financial gamble.

The proper protection is all-risk cargo insurance. This separate policy covers the full declared value of your equipment against loss or damage during transit. The premium is typically a small fraction of the equipment's value and is the only reliable way to safeguard your investment when exporting heavy equipment.

Common Questions on Exporting Heavy Equipment

https://www.youtube.com/embed/n-3rQUjSGtk

Navigating the complexities of heavy equipment shipping raises many questions. Here are clear, actionable answers to some of the most common inquiries.

Is a Freight Forwarder Really Necessary?

While not legally mandatory, attempting to export heavy equipment without a specialized freight forwarder is extremely risky. A forwarder acts as your logistics architect, managing documentation, negotiating carrier rates, coordinating transport, and troubleshooting customs issues. Their fee is a small investment compared to the potentially catastrophic costs of delays and non-compliance. View them not as an expense, but as essential risk mitigation.

How Long Does It Take to Ship Heavy Equipment Overseas?

Total transit time can range from a few weeks to over two months, depending on several variables:

- Ports of Origin and Destination: The ocean voyage itself is the largest factor. A direct route from the U.S. East Coast to Northern Europe might take 3-4 weeks.

- Carrier Routes: Direct services are faster. Shipments involving transshipment—where cargo is moved to a second vessel at an intermediate port—will take longer.

- Port Congestion and Customs: Delays at busy ports or slow customs processing can impact the schedule. A shipment from the U.S. Midwest to a remote Australian port could easily become a 6-8 week journey from door to door.

Always request a realistic door-to-door transit time estimate from your freight forwarder.

What Is the Most Common Mistake Exporters Make?

By far, the most frequent and costly error is inaccurate or inconsistent documentation. A typo on a serial number, a wrong HS code, or a value mismatch on the commercial invoice can halt a shipment indefinitely. These are not minor clerical mistakes; they are red flags for customs officials that can trigger inspections, fines, and severe delays. Have your customs broker meticulously review every document before submission.

A single documentation error creates a costly ripple effect. A machine detained by customs accumulates daily storage fees, frustrates your buyer, and damages your professional reputation. Never underestimate the importance of perfect paperwork.

Are There Special Rules for Shipping Used Equipment?

Yes, many countries have stringent regulations for importing used machinery. These rules often concern the equipment's age, emissions compliance (e.g., Tier 4 standards), and overall condition. Some nations require a certificate of cleanliness to prevent the import of foreign soil or pests. Before finalizing a sale, thoroughly research the destination country's import requirements for used equipment. You may need to provide detailed maintenance logs or arrange a pre-shipment inspection. This due diligence ensures the machine will be admissible upon arrival.

Navigating the complexities of exporting heavy equipment requires a partner with deep expertise and a commitment to getting it right. At We Will Transport It, we manage every detail of your international shipment, from inland transport to final delivery, ensuring your valuable assets arrive safely and on schedule. Ready to ship with confidence? Get your free quote today and let our experts handle the heavy lifting.