When you hear "shipping," you probably think of standard trucks moving boxes on the highway. But what happens when the cargo is a 100-ton bridge beam, a massive wind turbine blade, or an industrial boiler? That's where interstate heavy haulage comes in.

This isn't your average delivery service. It’s a highly specialized field focused on transporting cargo that exceeds standard legal size and weight limits, especially when that journey crosses state lines. It demands precise planning, specialized equipment, and a deep understanding of the complex web of state-by-state regulations.

What Exactly Is Interstate Heavy Haulage?

If standard freight is like driving a family sedan, interstate heavy haulage is like navigating a supertanker through a canal system. It is the process of moving enormous, awkward, or incredibly heavy items that cannot be disassembled. This includes critical assets like construction machinery, mining equipment, and prefabricated building sections.

These shipments are typically classified as oversized, overweight, or over-dimensional (OOG). The primary challenge arises when crossing state lines. Each state has its own specific regulations for what is permissible on its roads. A load that is legal in Texas may require an entirely different set of permits and escorts to be legal in Louisiana. This transforms every trip into a custom-planned logistical puzzle.

The Key Players in a Successful Haul

Executing a successful heavy haul is a team effort. It is a carefully coordinated operation between several specialists, where a single misstep can cause significant delays and costs. Clear communication and expertise at every stage are mandatory.

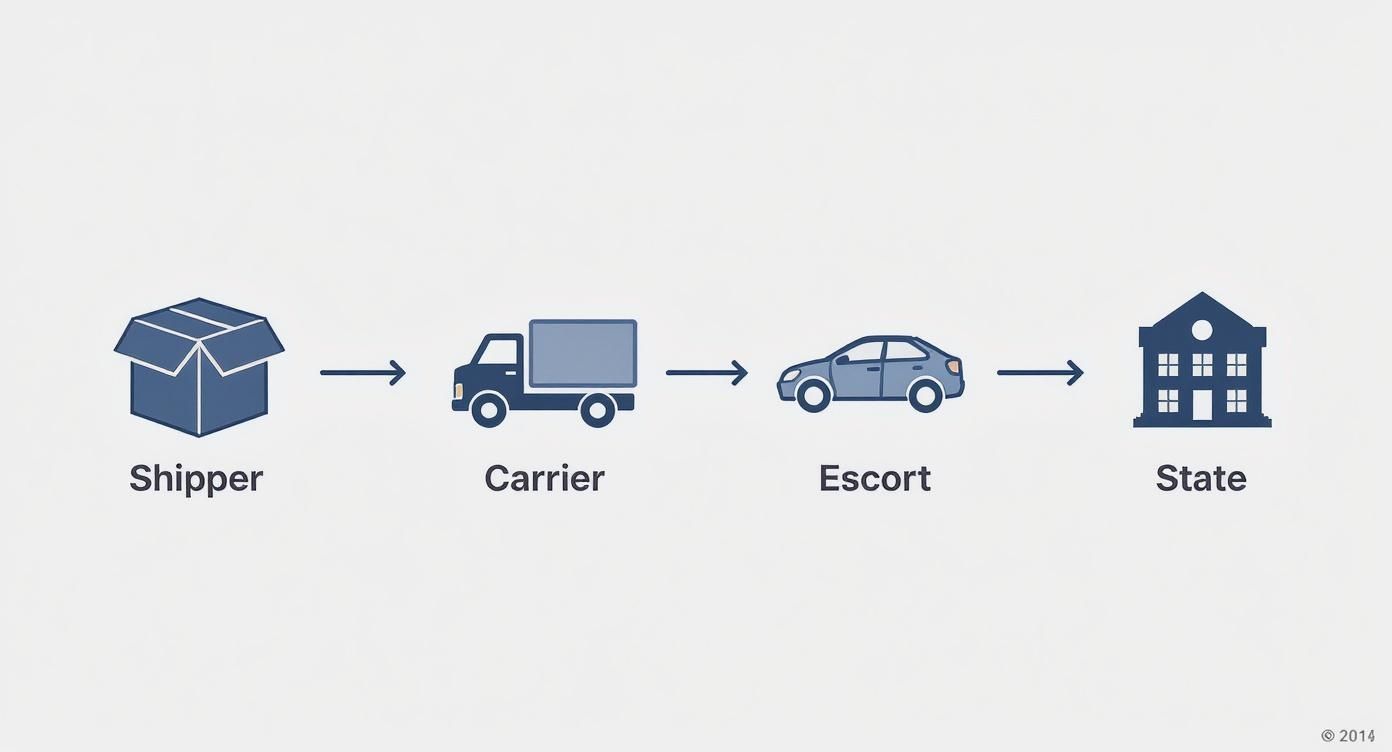

The infographic below outlines the roles in a typical heavy haul project.

As shown, the shipper, the carrier, escort teams, and various state authorities must collaborate seamlessly. The entire heavy-duty truck market—the backbone of these operations—is substantial, valued at around USD 391.16 billion in 2023. This sector is a cornerstone of the economy, moving nearly 70% of the nation's freight by weight. You can find a full analysis about the trucking market's future on truckingdive.com.

Why This Specialization Matters

Why is this specialized transport so critical? Industries like construction, energy, manufacturing, and aerospace depend on it. It is the only way to move the massive components needed to build a new power plant, a skyscraper, or a factory.

Interstate heavy haulage is the art of moving the immovable. It combines advanced engineering, regulatory mastery, and precise execution to transport the foundational components of modern infrastructure across the country.

This gives you a sense of the scale and precision involved. Understanding these core concepts is the first step. Next, we'll cover the actionable details of permitting, selecting the right equipment, and the safety protocols essential for every interstate heavy haulage project.

Navigating State Regulations and Permits

Successfully moving an oversized load across the country is less about horsepower and more about mastering a complex matrix of state-by-state regulations. Each time a heavy haul truck crosses a state line, it enters a new jurisdiction with its own rules, turning a direct route on a map into a challenging logistical exercise.

This is where the real work of heavy haulage begins. Planning an interstate heavy haulage route isn’t about finding the shortest path, but the most compliant one. This path must navigate a maze of differing state laws on weight limits, dimensions, and escort vehicle requirements. A load that is perfectly legal in one state can face steep fines or be shut down entirely a few miles into the next.

While the Federal Motor Carrier Safety Administration (FMCSA) sets national guidelines, it is each state's Department of Transportation (DOT) that issues the specific permits required for an oversized and overweight shipment.

Developing a Permit Strategy

An effective permit strategy is developed long before the cargo is loaded. It begins with a detailed route survey that meticulously assesses the regulations for every state the shipment will pass through. This proactive planning is the key difference between a smooth, on-time delivery and a costly logistical failure.

Think of it as planning a cross-country road trip with multi-million dollar assets at stake. You wouldn't just start driving and hope for the best; you'd check for road closures and construction. The principle is the same here, but the goal is to avoid thousands of dollars in fines and project-stopping delays.

A solid permit strategy must include:

- State-by-State Research: Identifying the specific dimension and weight thresholds that trigger permit requirements in each state.

- Route Optimization: Selecting a path that actively avoids regulatory bottlenecks, even if it adds miles to the journey.

- Timeline Management: Accounting for the fact that permit applications can take days, or even weeks, to be approved by state agencies.

Common Permit Types and Variations

The landscape of heavy haulage permits includes various specialized documents for different scenarios. A simple move might require only one or two permits, while a complex, multi-state journey could involve a thick portfolio of them.

These are not minor details. For example, one state might require a permit for any load over 80,000 pounds, while its neighbor sets the threshold at 85,000 pounds. That small difference has significant implications for your route, timeline, and budget.

The core challenge of interstate heavy haulage isn't just the weight of the cargo, but the weight of the paperwork. Every permit is a crucial piece of the puzzle, and a single missing document can halt the entire operation.

Understanding these variations is critical. For instance, the specific rules for Colorado heavy equipment transport will differ significantly from those in Florida or New York, affecting everything from approved roadways to permissible travel hours.

This table provides a high-level overview of the types of permits and factors you'll encounter.

Key Interstate Heavy Haulage Permit Considerations

| Permit Type / Factor | Description | Common State-to-State Variations |

|---|---|---|

| Oversize Permits | Required when a load exceeds standard legal dimensions (width, height, length). | Width thresholds (e.g., 8'6" vs. 10'), height limits, and rules for overhang can vary significantly. |

| Overweight Permits | Needed when a load's gross vehicle weight or axle weight exceeds state-mandated limits. | Maximum gross weight allowances, axle spacing requirements, and the availability of "superload" permits for extreme weights. |

| Route-Specific Permits | Permits that dictate the exact roads a shipment must travel to avoid unsafe bridges or low clearances. | Some states provide more flexibility, while others issue strict, turn-by-turn route approvals that cannot be deviated from. |

| Time of Travel Restrictions | Rules that limit heavy haul movement to specific days (e.g., no weekends) or hours (e.g., daylight only). | Curfews in metropolitan areas, holiday travel blackouts, and seasonal restrictions (like frost laws in northern states). |

As you can see, the complexity multiplies quickly when crossing multiple states.

Escort and Pilot Car Rules

Pilot cars (or escort vehicles) are your on-road safety system. They act as the eyes and ears for the truck driver, scouting ahead for hazards and managing traffic around the oversized load. However, the regulations for when they are required vary widely between states.

Here are a few practical examples of these variations:

- Width Requirements: A load that is 12 feet wide might only require one front pilot car in Arizona, but the same load crossing into California will legally require both a front and a rear escort.

- Height Requirements: For tall loads, often exceeding 14 feet 6 inches, a "high pole" escort may be mandated. This vehicle drives ahead with a pole set to the cargo's height to physically verify clearance under bridges and power lines.

- Length and Overhang: A long load or one with significant rear overhang typically requires a rear escort to maintain a safe following distance for other vehicles and assist the driver in navigating turns.

A carrier must know and comply with these rules for every mile of the journey. Being caught without a required escort is a guaranteed way to be shut down by law enforcement. The resulting delays and fines—which can easily reach thousands of dollars per violation—make a deep understanding of these state-specific laws absolutely essential for any successful interstate heavy haulage project.

Choosing the Right Equipment for the Job

Selecting the right trailer for an interstate heavy haul is like a surgeon choosing the correct instrument. It's a decision that dictates the success and safety of the entire operation. This choice goes far beyond simply finding a truck that's large enough; it requires a detailed analysis of the cargo’s weight and dimensions against the physical and regulatory challenges of the route.

The right equipment provides capability, not just capacity. The wrong trailer can lead to everything from permit violations to catastrophic failures. For example, a trailer that seems adequate for a transport in one state might become stuck at a low bridge in the next, triggering a cascade of costly delays and emergency rerouting.

Matching Trailers to Specific Cargo

The world of heavy haul trailers is highly specialized, with each design engineered to solve a specific transport problem. Knowing the function of each trailer type is the first step in planning a successful move. While a standard flatbed can handle some heavy items, specialized cargo demands a specialized solution.

Consider the common task of moving tall construction machinery. An excavator on a standard trailer can easily exceed legal height limits. This is where a Removable Gooseneck (RGN) trailer, also known as a lowboy, becomes indispensable.

-

Removable Gooseneck (RGN) / Lowboy: The front section of this trailer detaches, allowing it to lower to the ground and create its own ramp. This design enables equipment like excavators to be driven directly onto the trailer deck, which sits very low to the ground. This low profile provides the crucial clearance needed to pass safely under bridges and overpasses. Our guide to shipping an excavator provides more detail on this process.

-

Step-Deck (or Drop-Deck) Trailers: These trailers feature a two-level deck, offering better height clearance than a standard flatbed but less than an RGN. They are an excellent choice for cargo that is tall but will be loaded by crane.

-

Multi-Axle Modular Trailers: For truly monumental cargo—like a power plant turbine or a large bridge section—these are the only viable option. These systems can be configured with dozens of axles to distribute immense weight, ensuring compliance with strict road and bridge load limits.

The Critical Role of Ancillary Gear

While the trailer is the main component, a successful interstate heavy haulage operation relies on a full suite of supporting equipment. These are not optional extras; they are integral parts of the safety and logistics plan.

Escort vehicles, or pilot cars, are the most prominent example. They are the mobile command center of the operation, scouting the road for obstacles, managing traffic, and maintaining constant communication with the driver. Then there is the rigging—the chains, straps, and binders used to secure the load. Using improper or poorly maintained rigging is a leading cause of transport accidents.

Choosing the right equipment isn't just about moving a load from point A to point B. It's about engineering a solution that accounts for every bridge, every state line, and every potential obstacle along the way.

Maintaining these specialized trailers is just as important as selecting the right one. A rigorous maintenance schedule is the only way to prevent mechanical failures that could endanger the public, the driver, and the cargo. For fleet managers, following a comprehensive trailer maintenance checklist is not just a best practice—it is essential.

Real-World Equipment Selection Scenarios

Let's apply this with two practical examples to illustrate why these choices are so critical.

-

The Cargo: A 15-foot-tall industrial press.

- The Wrong Choice: A standard flatbed trailer. The combined height would be illegal and physically impossible on most interstate routes.

- The Right Choice: An RGN/lowboy trailer. Its ultra-low deck height is the only way to safely transport the load under the 16-foot clearances of many older overpasses.

-

The Cargo: A 250,000-pound generator.

- The Wrong Choice: A standard 9-axle trailer. The weight concentration per axle would be dangerously high, violating road regulations and risking severe damage to infrastructure.

- The Right Choice: A multi-axle modular trailer. By distributing the immense weight across numerous axles, the load-per-axle remains within legal limits, making the transport both possible and safe.

Each piece of equipment has a specific function. When selected correctly, they work in concert to transform a seemingly impossible move into a routine, successful delivery.

Understanding the True Costs of Heavy Haulage

A quote for an interstate heavy haulage project is more than just a single price; it's a detailed breakdown of multiple cost components. The final figure is a composite of fixed rates, variable surcharges, and fees for the specialized services required for your specific job.

The process is similar to building a custom home. You begin with a base construction cost, but quickly add expenses for permits, specialized labor, and site-specific challenges. In heavy haulage, the initial freight rate is the foundation; the true cost emerges once all essential logistical elements are included.

Deconstructing the Core Costs

Every heavy haul quote is built on several fundamental financial components. These are the expenses present in nearly every transport and form the bulk of your initial estimate. Understanding these core elements is the first step to comparing quotes effectively.

Here are the primary costs you will always encounter:

- Base Freight Rate: The core charge for the truck, driver, and specialized trailer needed to cover the transport distance. It is typically calculated per mile, with the rate varying based on the carrier and route complexity.

- Fuel Surcharge: To account for fluctuating diesel prices, carriers add this surcharge to the base rate. It protects them from market volatility and is usually adjusted weekly.

- Labor Costs: This includes not only the driver's time on the road but also time spent waiting during loading and unloading, as well as mandatory rest periods.

These costs are not static. Operational expenses for interstate heavy haulage are on an upward trend. Projections indicate that by 2025, diesel fuel costs are expected to reach USD 4.80 per gallon, up from USD 4.15 in 2023. During the same period, preventive maintenance is projected to climb from USD 0.42 to USD 0.51 per mile, and driver wages are likely to increase from USD 0.78 to USD 0.85 per mile. You can learn more about upcoming heavy haul trucking trends on freedomheavyhaul.com.

The Variable and Hidden Expenses

Beyond the basic costs, a host of other expenses can significantly impact the final invoice. These are often the "hidden" costs that can be a surprise if you are not prepared. They are directly tied to the unique requirements of your cargo and its route.

A heavy haulage quote is a living document. It adapts to the complexities of the route, the dimensions of the cargo, and the specific regulations of every state it passes through.

These variable costs are where a deep understanding of the transport process provides value. They are not optional—they are mandatory for a legal and safe journey.

Key variable expenses to anticipate include:

- State Permits: Each time your load crosses a state line, it enters a new regulatory environment, requiring a new set of permits for being oversized or overweight, each with an associated fee. A long, multi-state journey can result in a significant paperwork and fee total.

- Pilot Cars and Escorts: If your load meets certain width, length, or height criteria, you will be legally required to hire escort vehicles. Depending on the state and the load's dimensions, you may need one, two, or even a police escort, each adding a substantial cost.

- Route Surveys: For exceptionally large loads, a professional route survey may be mandatory to verify clearances, check for weak bridges, and ensure turns are navigable.

- Specialized Handling: This category includes fees for services such as cranes for loading and unloading, as well as any special rigging or tie-down procedures.

Furthermore, insurance is a critical cost factor. Beyond direct operational expenses, understanding your liability insurance coverage is essential for calculating the true cost and managing the inherent risks of interstate heavy haulage.

Factors That Drive Prices Higher

Finally, certain external factors can have a major impact on your quote. These often relate to timing, location, and broader market conditions. Awareness of these factors can help you plan a more cost-effective shipment.

For example, scheduling a haul during peak construction season can lead to higher prices due to increased demand for trucks and escorts. Routes that must navigate difficult mountain passes or congested urban areas will always be more expensive than a straight route across open country. Even the time of year is a factor—winter weather in northern states can cause delays and require additional planning, adding to the final cost.

Executing a Safe and Efficient Transport

In interstate heavy haulage, securing permits and equipment is only half the job. The real test is the execution of the transport. Much like a space launch, extensive preparation is vital, but flawless execution is what determines success. A single oversight can lead to catastrophic damage, project-ending delays, or worse.

This is about more than just following a checklist. It's about a deep-seated culture of safety that protects your cargo, the transport crew, and the public. A successful haul is defined by its safe, on-time arrival without incident.

The Foundation: A Detailed Route Survey

Before the truck engine starts, a thorough route survey serves as the first and most critical line of defense. This is not a quick look at a map; it is a meticulous, mile-by-mile analysis of the entire journey, designed to identify and mitigate risks before the transport begins.

A professional team will physically or digitally map every critical point, documenting any potential obstacle that could disrupt the move.

Here’s what a route survey identifies:

- Vertical Clearances: Every low bridge, overpass, and power line is measured and accounted for.

- Weight Restrictions: The survey confirms that every bridge and road segment can safely handle the gross and axle weights of the loaded truck.

- Road Geometry: Tight turns, steep grades, and complex interchanges that could be impassable for an oversized vehicle are flagged.

- Temporary Obstacles: Active construction zones, sudden road closures, and seasonal restrictions are noted to prevent last-minute detours.

There are no shortcuts in this process. Discovering a bridge is an inch too low when you are directly in front of it is a logistical disaster.

Mastering Load Securement Techniques

Once the route is confirmed, the focus shifts to securing the cargo. This is both a science and an art, governed by strict regulations from the Federal Motor Carrier Safety Administration (FMCSA). The best carriers don't just meet these standards; they exceed them.

Proper securement involves using the correct combination of chains, binders, straps, and blocking to ensure the load cannot shift, tip, or fall. Each piece of securement equipment has a specific working load limit (WLL), and the combined WLL of all tie-downs must be at least 50% of the cargo's total weight. This redundancy provides a critical safety margin.

In heavy haulage, the chains holding the load are only as strong as the plan that put them there. Meticulous securement isn't just a task—it's the core principle that ensures an uneventful journey.

The stakes are extremely high. In 2022, large trucks were involved in 166,853 accidents in the United States, resulting in 5,276 fatalities. With 71% of those deaths being occupants of other vehicles, the responsibility to secure cargo correctly is a critical matter of public safety. You can find more of these critical trucking industry statistics on geotab.com.

Constant Communication and Contingency Planning

Finally, communication is the operational glue. The driver, dispatch office, and escort vehicle operators must maintain constant contact. This real-time link allows the team to react instantly to unforeseen challenges, from sudden weather events to unexpected traffic congestion.

A robust operational plan always includes a Plan B. What happens if a road is unexpectedly closed? Is there a pre-approved alternate route? What if a piece of equipment fails? Having contingency plans for these common scenarios turns a potential crisis into a manageable problem, ensuring your interstate heavy haulage project stays on schedule and concludes safely.

How to Select a Heavy Haulage Partner

Choosing the right carrier for your interstate heavy haulage project is the most critical decision you will make. This is not about finding the lowest price; it is about establishing a partnership. You are entrusting a high-value, often irreplaceable, asset to a team that must execute flawlessly across state lines. A low bid from an unqualified carrier can quickly become an expensive failure.

Your vetting process must be deliberate and comprehensive. Begin by looking for a partner with a verifiable track record of handling loads similar to yours—not just in weight, but in dimensions and complexity. A company specializing in moving bulldozers may not be the right choice for a fragile, oversized manufacturing component, even if the weight is comparable.

Asking the Right Questions

Once you have a shortlist of potential carriers, it's time to ask direct questions. Their answers will reveal their professionalism and operational competence. Do not hesitate to ask for specifics; a reputable partner will have this information readily available.

Your initial conversation should cover these non-negotiable points:

- Experience: "Can you provide case studies for three recent shipments similar to my cargo?"

- Safety Record: "What is your current CSA score? Can you provide your USDOT number so I can verify it?"

- Insurance Coverage: "What are your cargo and liability insurance limits? I will require a certificate of insurance before booking."

These questions establish a baseline for qualification. If a carrier becomes defensive or provides vague answers, it is a significant red flag.

Trust in heavy haulage is built on a foundation of verified experience and transparent safety records. Moving beyond a quote to scrutinize a carrier's history is the only way to protect your investment and ensure a successful transport.

Verifying a Carrier's Credentials

The good news is that you don't have to take a carrier's claims at face value. The Federal Motor Carrier Safety Administration (FMCSA) provides tools for independent verification. The most powerful of these is the Safety and Fitness Electronic Records (SAFER) System.

By entering a carrier's USDOT or MC number into the SAFER database, you can instantly see their:

- Operating Authority: This confirms they are legally authorized to operate as a for-hire carrier.

- Safety Rating: This shows their official safety fitness determination from the FMCSA.

- Insurance Status: This verifies that their required insurance policies are active and on file with the government.

This simple check is an essential step in due diligence. It cuts through sales pitches and provides the hard data needed to assess a carrier's true performance.

Ultimately, selecting the right partner means finding a company that communicates clearly and demonstrates a commitment to regulatory compliance and safety. Reviewing the services of experienced heavy haulers can provide a useful benchmark for your own search. A reliable carrier acts as an extension of your team, prepared to manage the complexities of your interstate heavy haulage project with the necessary expertise.

A Few Common Questions

When you're dealing with interstate heavy haulage, a lot of questions pop up. It's a complex world, so let's clear up a few of the most common things people ask.

How Far Ahead Should I Book a Heavy Haul?

The short answer: as far in advance as possible. For any complex, multi-state transport, you should plan for a lead time of at least 30 days.

This may seem long, but this timeframe is crucial. It allows your transport partner to properly manage critical details, such as:

- Conducting route surveys: A professional team physically drives the route to identify low bridges, tight turns, or road construction before your transport begins.

- Applying for permits: Securing permits from multiple state agencies is a slow, bureaucratic process that can take weeks.

- Scheduling resources: Coordinating the right truck, trailer, and certified escort vehicles for your specific dates requires advance planning.

While a simple, in-state haul might be arranged in a week or two, rushing an interstate project often leads to higher costs and significant delays. The best practice is to contact your carrier as soon as you have your shipment's specifications.

What's the Difference Between "Overweight" and "Over-Dimensional"?

These terms are often used interchangeably, but they have distinct meanings. A shipment can be one, the other, or both, and each classification requires different permits and handling.

An over-dimensional load exceeds standard legal limits for width, height, or length. An overweight load is one where the gross vehicle weight (truck, trailer, and cargo) exceeds the legal weight limits for the roads or bridges on its route.

Consider this: a massive but lightweight wind turbine blade is over-dimensional due to its extreme length. Conversely, a dense industrial press might fit on a standard flatbed but be massively overweight.

When you have cargo like a giant mining excavator that is both extremely large and heavy, it enters "superload" territory, which is the most complex category of heavy haul, demanding the highest level of planning and specialized equipment.

Who Handles All the Permits?

This responsibility does not fall on you as the shipper. The task of securing all necessary state and local permits is the sole responsibility of the heavy haulage carrier.

An experienced carrier has a dedicated team that specializes in permit acquisition. They understand the nuances of each state's Department of Transportation (DOT), manage all the complex paperwork, and ensure every legal requirement is met. Their expertise ensures the entire journey is 100% compliant.

Your critical role as the shipper is to provide perfectly accurate dimensions and weight for your cargo. Even a minor error can invalidate a permit, resulting in fines and having your shipment shut down by authorities.

What Happens if There's a Delay?

Even the most meticulously planned transport can encounter unforeseen issues. A sudden blizzard, an unexpected road closure, or a mechanical problem can disrupt the schedule. This is where a professional carrier demonstrates its value. They don't panic; they execute contingency plans.

The moment a delay occurs, their team begins problem-solving. They will work to find a viable new route (and secure the new permits for it) or identify a safe place to hold over until the issue is resolved. Most importantly, they will maintain clear communication with you. Constant updates are standard practice, ensuring you are never left wondering about the status of your shipment.

Planning a complex move requires a partner you can trust. We Will Transport It has the experience and expertise to manage every detail of your interstate heavy haulage needs. Get your free, no-obligation quote today!