Shipping an oversized load is far more than just finding a big enough truck. It's a specialized corner of the logistics world that demands meticulous planning, a deep understanding of regulations, and precisely the right equipment for the job. Success starts with a simple fact: any shipment that goes beyond the standard legal dimensions requires a unique transport strategy.

Get this first part wrong, and you're setting yourself up for costly delays and fines. We're talking about shipments that are wider than 8.5 feet, taller than 13.5-14.5 feet, or tip the scales at over 80,000 pounds. Getting these behemoths from point A to point B safely and on budget is all about the prep work.

Your Foundation for Shipping Oversized Loads

When you're dealing with oversized freight, you have to think like a problem-solver from the very beginning. Long before a single chain is tightened, a solid, comprehensive plan must be locked in. This isn’t just about getting something down the road; it’s about navigating a maze of state-by-state rules, infrastructure limits, and critical safety protocols.

It all kicks off with a detailed assessment of your cargo. You must provide the exact numbers: length, width, height, and weight. These aren't just suggestions—they are the four pillars that determine every subsequent action, from the type of trailer you'll need to the permits you have to secure and the exact route the truck is legally allowed to take.

What Makes a Shipment "Oversized"?

As soon as a load crosses the standard legal limits set by the Department of Transportation (DOT), it officially becomes "oversized" or "over-dimensional." The specifics can vary a bit from one state to the next, but the general thresholds are consistent nationwide.

To help you see where your shipment might land, here’s a practical rundown of the dimensions that separate a standard haul from an oversized one.

Standard vs Oversized Load Dimensions Overview

| Dimension | Standard Legal Limit (Typical) | Common Oversized Threshold | Key Consideration |

|---|---|---|---|

| Width | 8 feet 6 inches (102 inches) | Anything wider than 8' 6" | This is the most frequent reason for needing an oversized permit. |

| Height | 13 feet 6 inches | 13' 6" to 14' 6" (varies by state) | Bridge and overpass clearances are the main operational concern here. |

| Length | 48 or 53 feet (trailer length) | Exceeding trailer length or significant overhang | The overall length of the truck, trailer, and load is regulated. |

| Weight | 80,000 pounds (Gross Vehicle Weight) | Anything over 80,000 lbs | Exceeding the gross limit or individual axle limits requires an overweight permit. |

Getting these classifications right from the start is non-negotiable. An experienced logistics partner can help you navigate these rules to ensure you’re fully compliant before you even think about hitting the road.

The real challenge with oversized freight is buried in the details. Being off by just a few inches or pounds can spiral into getting the wrong permits, facing steep fines, creating dangerous road conditions, or getting shut down at a weigh station.

Key Milestones in the Transport Process

Understanding the transport journey from start to finish helps you see just how much precision is involved. The whole operation is a sequence of carefully managed steps, where each one depends on the last. It's a major undertaking, powering a global market valued at around $204.81 billion. With projections showing growth to $213.62 billion, it's clear how essential this service is for industrial and infrastructure projects. You can find more insights about the oversized cargo transportation market and its economic impact.

A typical heavy haul project breaks down into several key phases:

- Initial Assessment & Quoting: Provide exact dimensions and weights to get a realistic, actionable quote.

- Route Planning & Surveying: The carrier identifies the safest route, flagging potential obstacles like low bridges, tight turns, or construction zones. For superloads, this is a physical inspection.

- Permit Acquisition: Your logistics partner applies for and secures all the necessary state and local permits for that specific route. This is a complex step, as requirements change at every state line.

- Carrier & Equipment Selection: Match your cargo to a carrier with a proven track record in heavy hauling and the right specialized trailer.

- Loading & Securing: The cargo is carefully loaded to balance weight and then secured according to strict federal safety standards.

- Transportation & Escorts: The actual move begins, often with pilot cars (escorts) in front and behind to ensure safety for the driver and the public.

- Delivery & Unloading: The final step is arriving safely and having the right equipment on-site to unload the cargo efficiently.

Every single one of these steps requires real-world expertise. Partnering with a seasoned logistics provider is the most effective way to ensure your oversized shipment is executed flawlessly.

How to Navigate Permits and Regulations

If you get one thing right when shipping an oversized load, make it the paperwork. Mastering the legal landscape isn't just about avoiding tickets; it's the foundation of a safe, on-time, and on-budget haul. One mistake in permitting or a missed regulation can bring your entire project to a screeching halt, racking up steep fines and creating serious safety hazards along the way.

The real challenge? There’s no single rulebook. The permit that gets you through Texas is useless once you hit the Oklahoma state line. Every state, and sometimes even individual counties, has its own unique set of requirements. This is exactly why a detailed, state-by-state game plan is non-negotiable before your truck's wheels ever start turning.

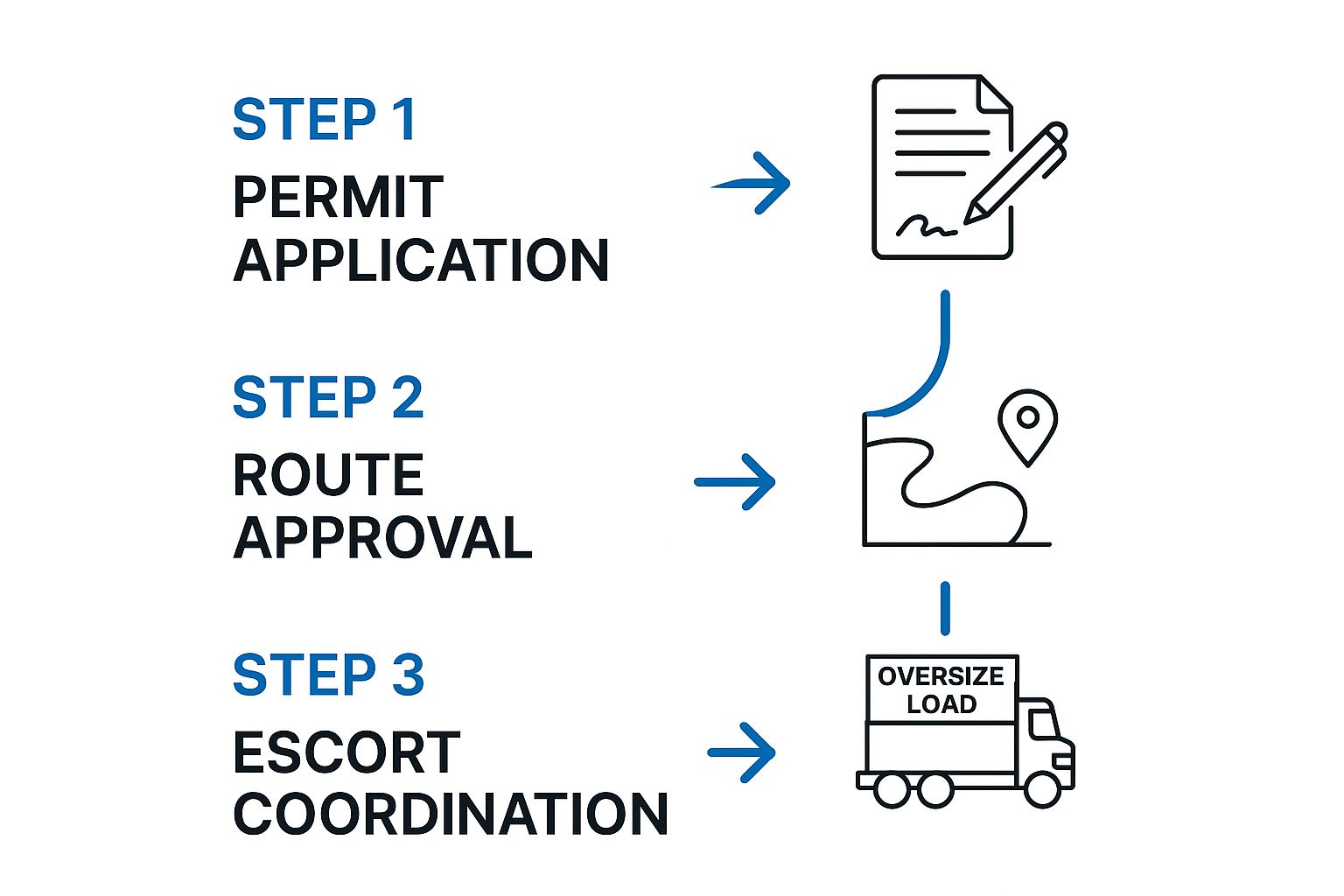

This process isn't as simple as just filling out a form. It's a sequence of deliberate steps to ensure your shipment is fully compliant before it ever leaves the yard.

As you can see, each stage builds on the one before it. From the initial application to coordinating the final escort plan, following this flow is your clearest path to getting everything right.

Decoding Permit Types

Not all permits are created equal, and knowing the difference is the first step toward smart, cost-effective planning. The right permit for your haul really depends on how often you ship, the exact route you're taking, and what you're moving.

Here’s an actionable breakdown of the common permit types:

- Single-Trip Permits: This is the most common permit. It's a one-time permit issued for a specific load moving along a pre-approved route. They’re typically only valid for a few days, just long enough to get from point A to point B.

- Multi-Trip or Annual Permits: If you're constantly moving similar loads over the same routes, these can be a game-changer. They save a ton of time and money by allowing multiple trips within a state over a longer period, but they come with very specific limits on weight and dimensions.

- Superload Permits: This category is for exceptionally massive loads—think wider than 16 feet or heavier than 200,000 pounds. Getting a permit for these giants requires a much deeper dive, often involving structural engineers who must approve every bridge and overpass along the way.

Picking the right permit from the get-go is critical. A good logistics partner can be invaluable here, but you can also get a head start by exploring our detailed guide on https://www.wewilltransportit.com/oversize-transport-permits/ for more specifics.

The Critical Role of Route Surveys

For many oversized loads, especially those pushing the limits on height or width, a route survey isn't optional—it's mandatory. This is where the plan on paper meets the real world. A surveyor will physically or digitally inspect the entire proposed path to pinpoint any obstacle that could stop your truck in its tracks.

They’re looking for deal-breakers like:

- Low bridges and overpasses

- Roads with weight restrictions

- Sharp turns or narrow lanes the truck can’t handle

- Roundabouts that are impossible to navigate

- Low-hanging power lines or traffic signals

A thorough route survey is your shipment’s insurance policy against disaster. Finding out a bridge is too low when you're already on the road is a nightmare scenario. It means turning around, finding a new route on the fly, and eating massive costs and delays. A little planning upfront prevents all of that.

Understanding Pilot Car Requirements

Pilot cars (or escort vehicles) are your eyes and ears on the road. They are a non-negotiable safety measure for most oversized moves, responsible for warning other drivers, communicating with the trucker about upcoming hazards, and helping navigate tricky spots.

The rules for how many pilot cars you need change from state to state and are tied directly to your load's dimensions. For instance, a 12-foot-wide load might only need one front escort on a two-lane road in one state. Cross the state line, and you might suddenly need a pilot car in both the front and the rear.

As a general rule of thumb:

- One Escort: Often required once a load gets wider than 10 to 12 feet.

- Two Escorts: Typically mandatory for anything stretching beyond 14 to 16 feet wide.

- Police Escorts: Reserved for true superloads, especially when moving through cities or navigating complex intersections where public safety is the top priority.

Getting a handle on complex rules, like the stringent hazmat shipping regulations, can offer great insight into the level of detail required for oversized compliance. This commitment to safety and rules is what defines specialized transportation.

Selecting the Right Carrier and Equipment

Alright, you’ve waded through the paperwork and have your permits in hand. Now comes the part where things get real: choosing the truck that will haul your load and the carrier you'll trust to get it there. This is where the rubber literally meets the road.

Trying to shoehorn a tall piece of machinery onto a standard flatbed isn't just a bad idea—it’s a dangerous and often illegal one. The entire success of shipping oversized loads comes down to getting this pairing right. An experienced carrier knows the ropes, and the correct trailer ensures your cargo is stable, secure, and ready for the highway. A misstep here can cause everything from minor equipment damage to a full-blown catastrophe.

Matching Cargo to the Correct Trailer

Let's be clear: not all trailers are created equal. When you're dealing with oversized freight, specialization is the name of the game. The specific dimensions and weight of your cargo will dictate exactly what kind of trailer is needed. Using the wrong one can put you at risk of hitting a bridge, creating an unstable center of gravity, or getting slapped with hefty fines for violating axle weight limits.

Here’s a functional guide to the heavy haul workhorses you’ll encounter:

- Step-Deck (or Drop-Deck) Trailers: These are your go-to for cargo that’s just a bit too tall for a standard flatbed. They have a higher front deck and a lower main deck, which gives you an extra 1.5 to 2 feet of crucial vertical clearance.

- Double Drop Trailers: Got something exceptionally tall? The double drop is your answer. It has a low-slung "well" between the axles that gets your cargo as close to the pavement as possible. It's the only way to move massive excavators or industrial equipment under low overpasses.

- Removable Gooseneck (RGN) Trailers: RGNs are lifesavers for heavy equipment you can drive, like bulldozers and combines. The front of the trailer actually detaches and drops to the ground, creating a convenient ramp. This means you can load and unload without calling in an expensive crane.

- Multi-Axle Trailers: When you’re dealing with serious weight, it’s all about spreading the load. By adding more axles, the weight per axle is reduced. This is how carriers legally move incredibly heavy items that would crush the standard 20,000 pounds single-axle limit.

Getting a feel for these options is critical. If you want to dig deeper, our guide on the major types of hauling equipment breaks it down even further.

How to Properly Vet a Heavy Haul Carrier

Once you’ve identified the right trailer for the job, you need to find a carrier who actually knows how to use it. Not every trucking company has the skill or the fleet for heavy haul. Vetting your partners is a step you simply cannot skip.

A carrier’s experience is your best insurance policy. An operator who has moved a similar piece of equipment a dozen times before knows the specific challenges, loading techniques, and route pitfalls that a general freight company would completely overlook.

It all starts with asking the right questions. Their answers will tell you everything you need to know about their competence and professionalism.

Crucial Questions for Your Potential Carrier

Before you even think about signing a contract, you need to get straight answers to these questions. If their responses are vague, that’s a huge red flag.

- What’s your experience with a load this specific size and weight? Don't just take their word for it. Ask for real-world examples of similar jobs they've completed.

- What are your company’s CSA (Compliance, Safety, Accountability) scores? The FMCSA manages these scores, and they give you a direct look at a carrier’s safety record. In this case, lower scores are better.

- Can I see your certificate of insurance? You need to verify their liability and cargo coverage. Make absolutely sure it's enough to cover the full value of your shipment if something goes wrong.

- What does your fleet maintenance program look like? A breakdown with a standard load is a headache. A breakdown with an oversized load is a logistical nightmare. You want a carrier with a rigorous maintenance schedule.

- How will we stay in touch during transit? You need a carrier who provides regular, proactive updates and gives you a single point of contact. The last thing you want is to be in the dark when your multi-ton asset is on the road.

Remember, this isn’t the time to shop for the lowest bidder. You're choosing a partner. The right one will operate like an extension of your own team, giving your high-value cargo the precision and care it demands.

Putting It All Together: A Guide to Safe Loading and Unloading

You’ve done the hard work of planning, permitting, and picking the right truck. Now comes the moment of truth: getting that massive piece of equipment onto the trailer. This is where the rubber really meets the road, and where a small oversight can spiral into a costly disaster.

This isn't just about muscle; it's about precision. A minor miscalculation during loading can lead to an unstable load shifting mid-journey or, even worse, cause damage during unloading. It all comes down to a well-oiled process built on preparation, clear communication, and an unwavering commitment to safety.

Before the Truck Arrives: Prep the Site

Your job starts long before you hear the rumble of a diesel engine. The loading zone has to be ready. That means walking the site and making sure the ground is firm, level, and clear of any debris or overhead hazards like power lines.

This isn’t just about making things look tidy. You need to be certain the ground can handle the immense weight of the truck, the cargo, and any cranes or forklifts without turning into a mud pit. It’s also the time to double-check that the crane you've hired is actually rated for the lift. Trying to hoist a 50-ton excavator with a 40-ton crane is a catastrophe waiting to happen.

Here’s an actionable pre-loading checklist:

- Solid Ground: Can the surface support the combined weight of everything involved? No sinking, no shifting.

- Check Your Clearances: Is there enough room—both side-to-side and overhead—for the truck and crane to get in, maneuver, and get out safely?

- Huddle Up: Get the driver, crane operator, and ground crew together for a pre-lift safety meeting. Everyone needs to know the plan, their role, and the "what ifs."

Getting the Weight Right and Tying It Down

With the site prepped, it's time to load. Placing a heavy, oversized piece of equipment on a trailer is a delicate science. The goal is simple: balance the weight perfectly to comply with axle weight limits and keep the trailer stable.

If you get it wrong—too much weight on one axle group, for instance—you’re asking for blown tires, suspension damage, or a load that handles dangerously on the highway. A skilled operator knows exactly where to place the cargo to spread that weight evenly and keep the center of gravity as low as humanly possible. This is the cornerstone of shipping oversized loads without incident.

The Federal Motor Carrier Safety Administration (FMCSA) is clear on this: improper cargo securement is a top cause of major trucking accidents. These aren't just guidelines; they're federal laws designed to keep your load from shifting, falling off, or becoming a projectile on the interstate.

Once it's in place, it's time to lock it down with a combination of chains, binders, straps, and chocks. The cargo's weight and shape dictate how many tie-downs you need. Every single anchor point on the cargo and the trailer needs a close inspection to ensure it can handle the intense forces of braking, accelerating, and turning. For really complex jobs, a solid understanding of rigging and lifting heavy equipment is non-negotiable.

Unloading: The Final, Critical Step

After a long haul, it's easy to get complacent. Don't. The unloading process demands the exact same level of planning and precision as loading. When the truck arrives, the first thing to do is another site assessment. Is the ground stable? Is the area clear?

Communication is everything here. The truck driver and the equipment operators on the ground must be in constant contact, using hand signals or two-way radios to coordinate every move. From the moment the first binder is released to the final placement, everyone needs to be on the same page. Rushing this last step is a rookie mistake that can undo an entire successful transport.

Think of it as the loading process in reverse:

- Site Check: Make sure the unloading zone is safe and ready.

- Team Huddle: Review the game plan with the crew on-site.

- Release Slowly: Don't just pop all the chains off. Remove tie-downs methodically only after the crane or lift has a secure hold on the cargo.

- Lift with Care: The operator should lift the cargo off the trailer slowly and smoothly, keeping it balanced at all times.

- Final Placement: Gently set the cargo down, make sure it's stable on its own, and only then detach the lifting gear.

Treating loading and unloading with the professional respect they deserve is how you protect your gear, your people, and your project's timeline.

How to Create a Realistic Shipping Budget

When you're dealing with shipping oversized loads, getting the budget right from the start is half the battle. The final invoice isn't just about miles on the road; it's a complicated mix of costs that can easily spiral if you aren't prepared. Building a solid financial picture is the only way to keep your project on track and profitable.

Many people make the mistake of just looking at the base rate. In reality, the true cost is a blend of logistics, legal paperwork, and specialized services. Every extra foot in width or ton in weight adds another layer of complexity—and expense.

Deconstructing the Total Cost of Your Shipment

To create a budget you can trust, you have to look past the per-mile rate and break down every single component. Think of it as a financial puzzle; understanding where each piece goes shows you where your money is actually going.

Several key factors will always shape your final shipping cost:

- Permit Fees: These are unavoidable and change drastically from state to state. A single-trip permit might cost you $60 in one state, but it could be hundreds more elsewhere, especially if you're crossing multiple county lines.

- Pilot Cars (Escorts): This is a significant cost. If your load's dimensions trigger the need for one or more escorts, you'll be paying per mile for each vehicle. This can easily add hundreds, or even thousands, to the total bill.

- Route Surveys: For unusually large or tall loads, a route survey is often mandatory. It’s a specialized service that maps out a clear path, and that cost gets passed directly onto your invoice.

- Specialized Equipment: A standard flatbed is one thing. But if you need a multi-axle RGN or a double-drop trailer, you're paying for more sophisticated—and more expensive—machinery.

- Fuel Surcharges: These are a moving target, shifting with the market. You'll see them on almost every freight bill, and there's no way around them.

If your company runs its own fleet, exploring options for equipment financing for small businesses can be a smart move for managing these high upfront and ongoing operational costs.

To give you a clearer idea, here's how these costs might break down on a typical oversized shipment.

Sample Cost Breakdown for an Oversized Load

| Cost Component | Description | Estimated Cost Range |

|---|---|---|

| Base Freight Rate | The core charge for transport, based on mileage, weight, and equipment. | $1,500 – $5,000+ |

| State Permit Fees | Mandatory permits required for each state the load travels through. | $150 – $750+ |

| Pilot Car/Escort | Cost for one or more escort vehicles, billed per mile. | $1.75 – $2.50 per mile |

| Route Survey | Professional survey to ensure a clear path for superloads. | $500 – $2,000+ |

| Fuel Surcharge | A variable percentage added to the base rate to cover fuel costs. | 20% – 40% of base rate |

| Special Handling | Fees for loading/unloading assistance or crane services. | $200 – $1,000+ |

This table is just an illustration, but it highlights how quickly the "extra" charges can add up to become a significant part of the total cost.

How to Get an Accurate Quote

If you want a quote you can actually count on, you need to arm your carrier with surgically precise information. Vague details lead to vague estimates that are guaranteed to change. To sidestep those surprise charges later, have the exact, verified details of your shipment ready to go.

A quote is only as good as the information you provide. Being off by even a few inches on height or a few hundred pounds on weight can trigger the need for different permits or an extra pilot car, completely changing the final cost.

Your carrier absolutely needs to know:

- Exact Dimensions: Length, width, and height—down to the last inch.

- Verified Weight: The precise total weight of the cargo, no guesswork.

- Origin and Destination: Full, correct street addresses for both pickup and delivery.

- Equipment Details: The make and model of the machinery being shipped, if applicable.

- Site Conditions: Any information about accessibility for loading and unloading is crucial.

Understanding Market Rate Fluctuations

The price you'll pay is never set in stone. In the United States, heavy equipment shipping rates can bounce between $3 and $8 per mile, and where you are makes a huge difference. For example, Western states might average around $2.95 per mile, while shippers in Southeastern states could see rates closer to $3.76 per mile.

These numbers also shift with the seasons. Demand often spikes during the busy construction months in spring and summer. Regional truck availability plays a huge part, too—if there are more loads than trucks in a certain area, you can bet you'll pay a premium. If your timeline is flexible, try planning your shipment during an off-peak season. You can often find much more competitive pricing.

Common Questions About Shipping Oversized Loads

Even the most seasoned project managers have questions when it comes to shipping heavy haul. It's a complex world filled with permits, regulations, and logistics that can feel overwhelming. Let's walk through a few of the most common questions we hear from clients to help you plan your next move with confidence.

How Much Lead Time Is Really Necessary?

This is a critical question, and the most common mistake is not leaving enough time. For a relatively simple oversized load moving within a single state, you should give your logistics partner at least five to seven business days. That's usually enough time to line up the right permits and book a qualified carrier.

But that's just the starting point. The timeline can stretch out fast.

- Crossing State Lines: If your haul needs to travel through multiple states, plan on a lead time of two to three weeks. Every state has its own Department of Transportation, its own rules, and its own processing times for permits.

- True Superloads: For the really big stuff—the kind that gets classified as a "superload"—you could be looking at a month or even more for planning. These shipments often need detailed route surveys, bridge engineering studies, and coordination with police escorts, all of which takes a significant amount of time.

Rushing the planning is the surest way to invite delays and watch your costs skyrocket. Giving your team enough breathing room allows them to navigate all the red tape and find the smartest, most affordable solution for your shipment.

What Kind of Insurance Should I Expect?

When you're moving high-value machinery, insurance isn't just a good idea—it's absolutely essential. Your carrier must provide you with a Certificate of Insurance (COI) that spells out exactly what's covered. Don't just glance at it; read it carefully to make sure the coverage limits are high enough for your cargo's full value.

Typically, carrier insurance includes two main parts:

- Liability Insurance: This covers damage to other people's property or injuries in case of an accident.

- Cargo Insurance: This is what protects your shipment from damage or loss while it’s on the road.

Always double-check the cargo insurance limit. If your piece of equipment is worth $500,000 but the carrier's policy maxes out at $250,000, you’re exposed to a massive financial risk. If you find a gap like this, you’ll need to get a separate, supplemental insurance policy for the trip.

Handling Unexpected Delays and Route Changes

You can plan everything down to the last detail, but sometimes, life happens. A surprise road closure, a pop-up construction zone, or a sudden storm can throw a wrench in the works and force a detour. This is where a truly experienced carrier shows their value.

A pro heavy haul team always has a backup plan. When a route change is unavoidable, the driver is on the phone with their dispatcher and escorts immediately. From there, the logistics team jumps into action.

They'll work quickly to:

- Find a New Path: They’ll figure out a safe, legal alternative route that can accommodate the load.

- Fix the Permits: The team gets on the phone with state officials to amend the permit or apply for a new one. This is non-negotiable—the original permit is only good for the approved route.

- Keep You in the Loop: A great partner will call you, explain the delay, what they're doing about it, and give you a new ETA.

These situations can be frustrating, for sure. But they really drive home how important it is to work with a carrier who knows how to solve problems under pressure. Their ability to manage these hiccups is what separates a successful haul from a disaster.

Navigating the world of heavy haul takes a partner with real-world experience and a rock-solid process. At We Will Transport It, our logistics experts handle every single detail—from permits and route planning to final delivery—to make sure your valuable cargo gets where it needs to go, safely and on time.

Get your free oversized load shipping quote from We Will Transport It today!