Transporting a forklift requires a systematic approach to ensure safety and prevent damage. This guide offers actionable steps, from pre-transport mechanical checks to final on-site inspections. A successful move hinges on diligent preparation, selecting the right equipment, and adhering to transport regulations. These aren’t just recommendations; they are critical actions for protecting your investment and ensuring a smooth, secure transit.

Your Pre-Transport Forklift Preparation Plan

Proper preparation is a non-negotiable first step that prevents damage, delays, and safety hazards. An unnoticed hydraulic leak, for instance, can coat a trailer bed in slick fluid during transit, creating a dangerous situation for the unloading crew. This section details the critical checks and actions needed before your forklift is loaded. Each step is designed to mitigate a specific risk associated with transporting a forklift.

Conduct a Detailed Mechanical Inspection

A transport-specific inspection is more rigorous than a daily operator check. It is designed to identify issues that could be exacerbated by road vibrations and the stress of transit. Focus your inspection on these key areas to ensure the forklift is mechanically sound for the journey.

Here are the essential checks:

- Fluid Leaks: Thoroughly inspect all hydraulic lines, the engine, and the transmission for any drips or seepage. Minor leaks can worsen during transport, potentially damaging the trailer or other cargo and creating a slip hazard.

- Brakes and Steering: Confirm the brakes are fully operational for safe loading and unloading. Test the steering mechanism to ensure it is responsive and has no excessive play, which is critical for precise maneuvering onto the trailer.

- Tire Condition: Check each tire for correct inflation pressure, deep cuts, or significant wear. A tire failure during loading can instantly destabilize the forklift, posing a severe safety risk.

This proactive inspection identifies and resolves potential problems before they escalate into costly roadside repairs or accidents.

Actionable Insight: A forklift with a slow brake fluid leak might pass a routine check. However, during loading onto a steep ramp, the brakes could fail, causing the machine to roll back unexpectedly. A detailed, transport-specific inspection is your primary defense against such incidents.

Secure All Attachments and Moving Parts

Any component that can shift, swing, or detach during transport must be secured. The constant vibration of road travel can easily dislodge unsecured parts.

First, lower the forks completely to the trailer deck or as low as possible. Tilt the mast slightly forward to increase stability. Use a heavy-duty strap or chain to bind the forks together, preventing them from swinging independently and causing damage.

Removable attachments such as side shifters, rotators, or clamps must be either removed and shipped separately or secured firmly to the forklift’s frame. For a comprehensive approach, referencing professional pre-transport checklists can help ensure every component is accounted for and secured properly.

Prepare the Forklift for Loading

The final preparation steps involve neutralizing the machine and documenting its condition. Disconnect the battery to eliminate any possibility of an accidental startup during transit. This is a fundamental safety measure.

If the forklift is covered in significant dirt or mud, wash it. A clean machine makes it much easier to conduct a thorough damage inspection upon arrival and prevents debris from detaching on the highway.

Finally, take clear, dated photographs of the forklift from all angles just before loading. This visual record is your primary evidence if you need to file an insurance claim for any damage sustained during the move.

Forklift Weight and Corresponding Trailer Requirements

Forklifts range from compact models under 2,000 kg to heavy-duty machines exceeding 10,000 kg. This diversity means there is no single transport solution. Selecting the appropriate trailer based on the forklift’s weight is essential for stability, safety, and regulatory compliance. The table below outlines common forklift weight classes and the corresponding transport equipment required.

| Forklift Weight Class | Common Trailer/Truck Type | Key Considerations |

|---|---|---|

| Under 5,000 lbs (2,268 kg) | Tilt-deck or dovetail trailer | Enables easy ground-level loading, ideal for local moves. |

| 5,000 – 15,000 lbs (2,268 – 6,804 kg) | Standard flatbed trailer | The most common choice; requires a loading dock or portable ramp. |

| 15,000 – 30,000 lbs (6,804 – 13,608 kg) | Step-deck (drop-deck) trailer | Lower deck height offers superior overhead clearance and stability. |

| Over 30,000 lbs (13,608 kg) | RGN or Lowboy trailer | Best for oversized/overweight units; facilitates drive-on loading. |

Always confirm the forklift’s exact weight and dimensions with your transport provider. This ensures they dispatch the correct trailer, preventing delays and safety issues related to mismatched equipment.

Choosing Your Transport Hauler and Equipment

The safety and success of your forklift transport depend directly on your choice of hauler and trailer. This decision is not merely logistical; it involves matching your specific machine’s requirements with the right equipment and professional expertise. A mismatch can lead to delays, unexpected costs, or damage to your asset. An incorrect trailer selection, for example, could result in the forklift’s mast exceeding the legal height limit, causing significant routing problems and potential fines.

Matching the Trailer to the Forklift

The dimensions of your forklift dictate the type of trailer required. While a standard warehouse forklift may fit on a conventional flatbed (if a loading dock is available), larger or specialized models require specific solutions.

A telehandler or a forklift with a high mast presents a significant clearance risk. For these machines, a step-deck or a lowboy (RGN) trailer is necessary. These trailers have a lower deck height, providing critical extra vertical clearance. With legal height limits typically between 13.5 and 14.5 feet in most states, using a standard-height trailer for a tall forklift can easily result in an oversized load violation.

Actionable Insight: A job was delayed for hours when a driver arrived with a standard flatbed for a forklift that was one foot too tall for legal clearance. The necessary rerouting added significant time and cost to the transport—a problem caused entirely by an initial equipment mismatch.

How to Properly Vet a Transport Company

Once you know the required trailer type, you must select a qualified transport company. A low price can be a red flag for inadequate insurance or a poor safety history. Due diligence is essential to protect your investment.

Here is a checklist for vetting a carrier:

- Verify Their Insurance: Request a certificate of insurance and confirm that their cargo coverage meets or exceeds the full replacement value of your forklift. Standard liability coverage is insufficient.

- Check Their DOT Safety Record: Use their USDOT number to access their safety rating, inspection history, and accident record on the Federal Motor Carrier Safety Administration (FMCSA) database. This provides objective data on their operational safety.

- Ask for Relevant References: Speak with previous clients who have shipped similar equipment. Inquire about the carrier’s communication, punctuality, and the condition of the equipment upon arrival.

Communicating Site Capabilities

Clearly communicating the pickup and drop-off site conditions is a critical but often overlooked step. The driver must know what to expect to arrive prepared.

Provide clear details about the on-site environment:

- Loading/Unloading Equipment: State whether you have a loading dock or a ramp. If not, the carrier must provide a self-loading trailer, such as a tilt-deck or an RGN with integrated ramps.

- Site Accessibility: Describe the access route. A 53-foot trailer requires significant space to maneuver. Inform the driver about narrow streets, tight turns, or soft ground to prevent delays and potential additional fees.

Transparent communication about site logistics prevents surprises and ensures the driver is equipped for a smooth and efficient load/unload process. Understanding the overall logistics of heavy equipment transport will help you anticipate these requirements.

Loading and Securing Your Forklift for Transit

This phase requires precision and adherence to safety protocols. Loading and securing a multi-ton forklift is a deliberate process where rushing can lead to catastrophic failure. A slow, methodical approach is the only correct way. Always use a spotter to provide a second set of eyes, guiding the operator, checking clearances, and ensuring the machine remains centered on the ramps and trailer deck.

The Physics of Trailer Placement

Positioning the forklift on the trailer is a matter of physics, not convenience. The primary objective is to center the forklift’s weight directly over the trailer’s axles. This placement creates a low center of gravity and distributes the load correctly for safe transit.

Proper placement prevents two critical problems:

- Trailer Sway: Placing too much weight behind the axles creates a pendulum effect that can cause violent, uncontrollable swaying (fishtailing) at highway speeds.

- Poor Braking and Steering: Placing too much weight forward of the axles puts excessive pressure on the hitch, which can reduce the tow vehicle’s front-wheel traction and compromise steering and braking control.

Achieving the correct balance ensures the entire rig handles predictably and safely.

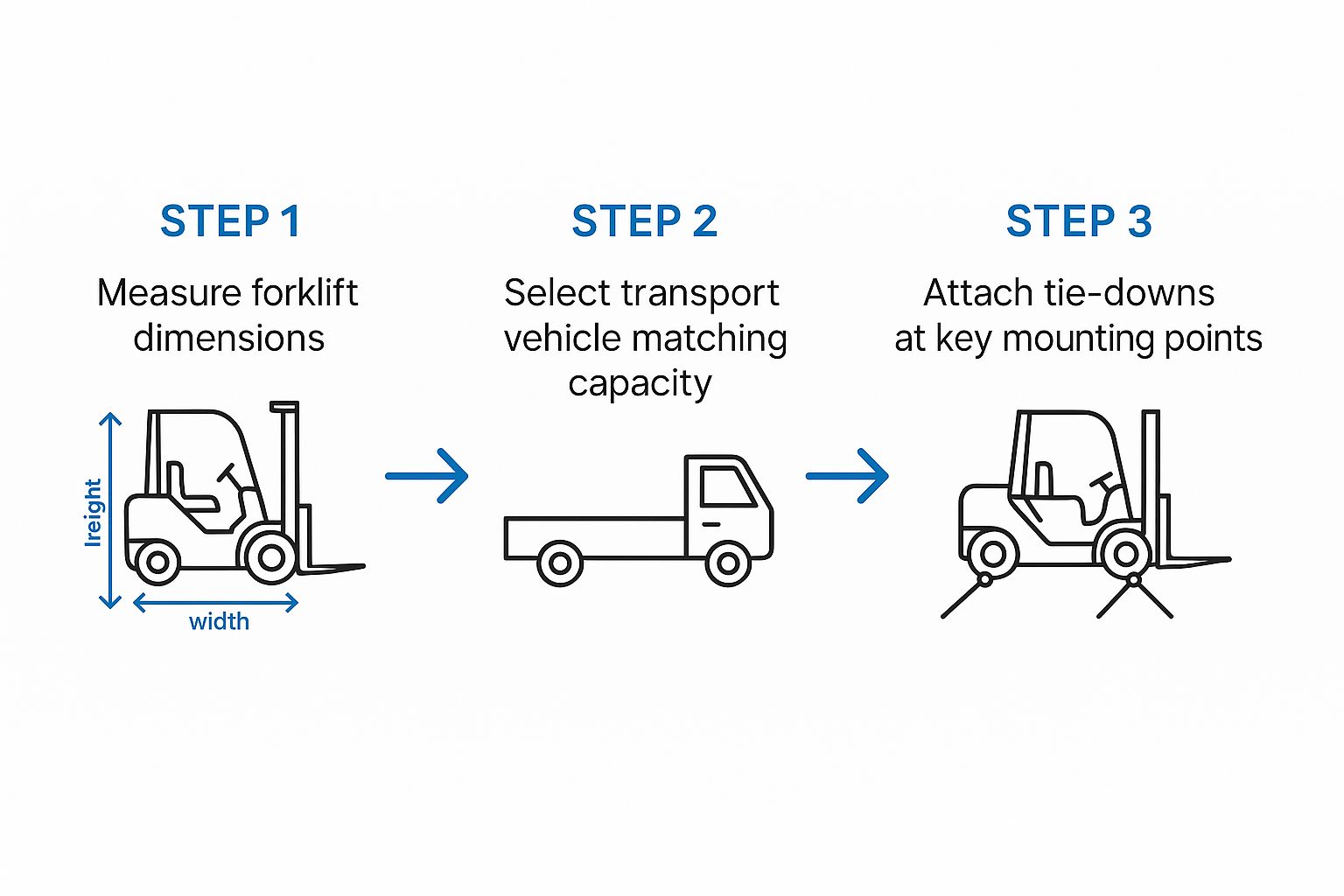

This is a great visual breakdown of the key steps.

As you can see, it flows from preparation to the all-important task of getting those tie-downs in the right spots.

A Deep Dive Into Proper Securement

Once the forklift is correctly positioned, it must be immobilized. For transporting a forklift, straps are inadequate. The industry standard is high-grade steel chains and load binders, which provide the necessary tension to secure multi-ton equipment.

Department of Transportation (DOT) regulations mandate a minimum of four separate tie-down points for equipment of this weight. Each chain must run from a corner of the forklift’s frame to a secure anchor point on the trailer, ideally at a 45-degree angle. This configuration creates opposing forces that prevent forward, backward, and lateral movement.

Actionable Insight: Never attach tie-down chains to the overhead guard or mast. These components are designed for lifting, not for withstanding the dynamic forces of transport. Anchoring to them can cause structural damage and lead to a dangerously loose load.

Avoiding Common Securement Mistakes

Knowing what not to do is as crucial as knowing the correct procedures. Complacency can lead to critical errors.

Avoid these common securement mistakes:

- Securing to the Mast: The mast assembly is not a structural tie-down point. Always anchor chains to the main frame or designated chassis tie-down points.

- Using Damaged Gear: Inspect all chains and binders before each use. Do not use chains with stretched links, bent hooks, or binders that are damaged or rusted. A single weak link compromises the entire securement system.

- Forgetting the Basics: Before applying chains, set the forklift’s parking brake and chock the wheels. This provides an initial layer of security.

- Not Achieving Enough Tension: Chains must be tensioned until they are “guitar-string tight.” After tightening the binders, there should be no slack. Any looseness invites load shift during transit.

Proper securement is a fundamental skill. A deeper understanding of rigging and lifting heavy equipment provides valuable context and enhances safety. Adhering to these details ensures your forklift arrives securely.

Navigating Transport Permits and Regulations

With the forklift secured, the final prerequisite is ensuring all legal paperwork is in order. Ignoring transport regulations can lead to significant fines, delays, and legal complications. Each state has specific rules defining what constitutes an oversized or overweight load, and a shipment that is legal in one state may require permits in the next. These regulations are in place to ensure the safety of public roadways.

Understanding Oversized and Overweight Loads

An “oversized” designation is not reserved for massive cranes; even a standard forklift on a specific trailer can exceed legal limits. You must know the total combined width, height, length, and gross vehicle weight of your loaded truck and trailer.

Generally, a load is considered oversized if it exceeds:

- Width: 8 feet 6 inches

- Height: 13 feet 6 inches

- Length: 53 feet (trailer length)

A load is typically classified as overweight if the gross vehicle weight exceeds 80,000 pounds. Exceeding these limits requires special permits.

Single-Trip vs. Annual Permits

If your shipment is oversized or overweight, permits are mandatory. Your transport provider should manage this process, but you should understand the basics.

- Single-Trip Permit: This permit is valid for one specific journey along a pre-approved route. This is the standard permit for nearly all one-off forklift moves.

- Annual Permit: This is used by companies that frequently transport similar oversized loads within the same state.

Actionable Insight: A client attempted to bypass the permit process for a “borderline” oversized forklift. The truck was stopped, resulting in a $2,500 fine and a two-day delay while the correct permits were rush-ordered. Adhering to regulations from the start is more efficient and cost-effective.

Banners and Pilot Cars

Permits come with specific requirements, which often include signage and, for larger loads, escort vehicles.

The yellow “Oversize Load” or “Wide Load” banner is a standard requirement. One must be placed on the front of the truck and another on the rear of the load, ensuring they are clearly visible.

Pilot cars (escort vehicles) are required when a load exceeds certain dimensional thresholds, which vary by state. For example, a load over 12 feet wide may require one pilot car, while a load over 14 feet wide may require both front and rear escorts. These vehicles create a safety buffer and assist the driver in navigating challenging road conditions. A professional hauler will plan the entire route, securing the necessary permits and arranging for pilot cars in every state to ensure continuous, legal transit.

Unloading and Final Inspection at the Destination

The transport job is not complete until the forklift is safely on the ground at its destination and has passed a final inspection. This concluding phase requires the same diligence as loading and preparation. Rushing the unloading process or skipping the post-trip inspection can lead to accidents or forfeit your ability to file a claim for transit-related damage.

Safe Unloading Procedures

Before beginning the unloading process, assess the drop-off site. The ground must be firm, level, and clear of obstacles. Unloading on soft ground, gravel, or an incline significantly increases the risk of a tip-over. Ensure there is adequate space for the truck to position itself and for the forklift to maneuver safely off the trailer.

Once the area is confirmed to be safe, follow this unloading sequence:

- Chock the Trailer Wheels: Securely chock the trailer wheels to prevent any movement during unloading.

- Remove Binders and Chains: Carefully release the tension on the load binders. Stand clear to the side when releasing tension, as binders can snap back forcefully. Remove all chains and store them out of the way.

- Position a Spotter: A spotter is mandatory for safe unloading. They will guide the operator down the ramp, ensuring the wheels remain centered and clear of edges.

- Back It Off Slowly: The operator should start the forklift, release the parking brake, and back the machine slowly and steadily down the ramp. Reversing provides better visibility and control on an incline.

Actionable Insight: Complacency is the biggest risk during unloading. An operator attempted to unload without a spotter on slightly uneven ground, causing one wheel to slip off the ramp. The multi-ton machine was left in a precarious, unstable position. Maintain focus until the forklift is securely on the ground.

The Critical Post-Trip Inspection

After unloading, conduct a thorough post-trip inspection to identify any issues that may have developed while transporting a forklift. This systematic check is your final opportunity to document damage for an insurance claim and to verify the machine’s operational safety.

Use a checklist to ensure a comprehensive inspection:

- Fluid Leaks: Inspect the ground beneath the forklift and check all hydraulic lines and fittings for new leaks. Road vibrations can loosen connections.

- Tire Condition: Re-check tire pressure and inspect for any new cuts or damage sustained during transit or unloading.

- Frame and Body: Perform a complete walk-around, looking for new dents, scrapes, or other physical damage. Compare the forklift’s current condition to the pre-trip photos you took.

- Hydraulic Functions: Start the forklift and test all hydraulic functions. Raise and lower the mast, tilt it, and operate any attachments to confirm they are working correctly.

- Document Everything: If you discover any new damage, photograph it immediately. Make detailed notes directly on the bill of lading before signing. This documentation is essential proof for filing a damage claim with the carrier.

This final inspection confirms the machine is safe for service and officially concludes the transport process.

Got Questions About Shipping Your Forklift? We’ve Got Answers.

When arranging heavy equipment transport, questions are inevitable. Addressing these concerns beforehand is key to a smooth and confident shipping experience. Here are direct answers to the most frequently asked questions about transporting a forklift.

What’s the Real Cost to Ship a Forklift?

The cost to ship a forklift is determined by several factors, so there is no single fixed price. Distance is the primary driver of cost. The forklift’s dimensions and weight are also crucial, as a larger, heavier unit may require a specialized trailer like a lowboy, which is more expensive than a standard flatbed. Fuel prices and permit fees for oversized loads also contribute to the final quote.

Here are some general cost estimates:

- Local Hauls (under 100 miles): Typically $300 to $700.

- Regional Trips (100-500 miles): Generally $700 to $2,000.

- Long-Distance Shipping (over 500 miles): Usually starts at $2,000 and increases based on distance and route complexity.

To get an accurate price, obtain detailed quotes from several reputable heavy equipment transport companies. This is the only way to secure a competitive and realistic rate for your specific needs.

Do I Need Special Insurance for This?

Yes, and proper insurance is non-negotiable. The transport company you hire must have cargo insurance sufficient to cover the full replacement value of your forklift. This is separate from their general liability policy and specifically covers damage to the freight they are hauling.

Before finalizing the shipment, take this critical action:

Request a copy of the carrier’s certificate of insurance. Verify the cargo coverage limit. If your forklift is valued at $50,000, but the carrier’s policy limit is only $25,000, you are exposed to significant financial risk. Do not proceed until you confirm their coverage is adequate.

Can I Just Drive the Forklift Onto the Trailer Myself?

Unless you are a certified operator with extensive experience loading heavy equipment onto trailers, it is strongly recommended that you let the professional driver handle it. Loading is a high-risk maneuver where a small error can have severe consequences. The driver has the experience and expertise to perform the task safely.

If you must load the forklift yourself, prioritize safety above all else. The trailer deck must be clean and dry. Use heavy-duty ramps rated for more than the forklift’s weight. And you must use a spotter to guide you. If you have any hesitation, defer to the driver.

What’s the Number One Mistake People Make?

The most common and dangerous mistake is improper securement. This includes a range of errors, such as using an insufficient number of tie-downs, using underrated straps instead of high-tensile chains and binders, or anchoring chains to non-structural points like the mast or hydraulic lines.

An improperly secured forklift can shift, slide, or even fall off the trailer, creating a life-threatening hazard. Always adhere to DOT regulations, which require a minimum of four securement points. Use appropriately rated chains and binders, and anchor them exclusively to the forklift’s designated frame tie-down points.

When you’re ready to move your equipment, you need a partner you can trust to handle the details from start to finish. We Will Transport It specializes in heavy equipment shipping, providing the expertise and reliable service needed to ensure your forklift arrives safely and on time. Get your free, no-obligation quote today.