When you need to ship heavy machinery, massive construction materials, or oversized equipment, a standard enclosed trailer simply won't work. This is the precise scenario where flatbed truck transport becomes essential. A flatbed trailer is the workhorse of the shipping industry, designed as an open, flat platform to handle large, heavy, or unconventionally shaped cargo that enclosed trailers cannot accommodate.

This guide provides actionable insights to help you navigate the flatbed shipping process, from choosing the right equipment to preparing your freight for a successful journey.

Unpacking Flatbed Truck Transport

At its core, flatbed truck transport utilizes trailers with an open-deck design. This key feature provides the versatility needed for freight that is too tall, wide, long, or heavy for a standard dry van. The absence of walls and a roof allows cargo to be loaded and unloaded from any direction—the sides, the rear, or directly from above with a crane or forklift. This flexibility is critical for handling items like:

- Bulky construction materials like steel I-beams and concrete pipes.

- Heavy machinery such as excavators, bulldozers, and farming tractors.

- Unusually shaped freight, think wind turbine blades or massive industrial tanks.

The Foundation of Industrial Shipping

Flatbed transport is the logistical backbone for essential industries, including construction, manufacturing, agriculture, and energy. With global industrialization and infrastructure projects on the rise, the growing flatbed truck market on businessresearchinsights.com is projected to expand significantly, highlighting its critical role in the economy.

Actionable Insight: Flatbed transport removes the dimensional constraints of enclosed trailers. It's the practical solution for moving the vital, oversized components that build our infrastructure, from urban high-rises to power grids.

While flatbeds are a key component, they are just one part of the heavy hauling ecosystem. To understand the full range of specialized equipment, it's useful to learn about the 6 major types of hauling equipment. And while this guide focuses on commercial transport, the principles of matching the right vehicle to the job apply across the board, even to personal decisions like exploring Ford truck lease options.

Choosing the Right Flatbed Trailer for Your Freight

Selecting the correct trailer for your flatbed truck transport is a critical decision. Using the wrong equipment can lead to loading difficulties, safety risks, transit delays, and unnecessary costs. Each trailer type is engineered to solve specific logistical challenges, from hauling standard materials to moving massive industrial machinery. Your choice will determine how the cargo is loaded, secured, and whether it complies with transport regulations.

The Standard Flatbed: A Versatile Workhorse

The most common trailer is the standard flatbed. These are typically 48 to 53 feet long and provide a simple, open platform for a wide range of loads. They are the go-to option for freight that can withstand exposure to the elements and can be easily loaded by forklift or crane.

Common uses include:

- Palletized goods like bricks or bags of cement.

- Construction materials such as steel beams and lumber.

- Scrap metal and other recyclable materials.

A standard flatbed can legally haul cargo up to 8.5 feet tall and 8.5 feet wide without special permits, with a maximum weight capacity of around 48,000 pounds.

Step-Decks and Double Drops: For Taller Freight

When your cargo exceeds 8.5 feet in height, you need a trailer with a lower deck. Step-deck (or drop-deck) trailers offer a lower main deck, providing additional vertical clearance for taller equipment. For example, shipping a large excavator on a standard flatbed might exceed the legal height limit of 13.5 feet (once loaded). A step-deck’s lower platform provides the necessary clearance to haul it legally. Double drop trailers take this a step further with an even lower "well" section between the axles, ideal for exceptionally tall items.

RGN Trailers: The Heavy Equipment Movers

For the heaviest and most challenging loads, the Removable Gooseneck (RGN) trailer is the premier solution. Its front section detaches, allowing the trailer to drop to the ground and create a drive-on ramp.

Actionable Insight: Choose an RGN when shipping self-propelled heavy equipment like bulldozers or pavers. This eliminates the need for a crane, making loading safer, faster, and more cost-effective by allowing the machinery to be driven directly onto the trailer.

RGNs are indispensable for transporting oversized and overweight machinery that other trailers cannot handle, making them a vital tool in heavy haul trucking.

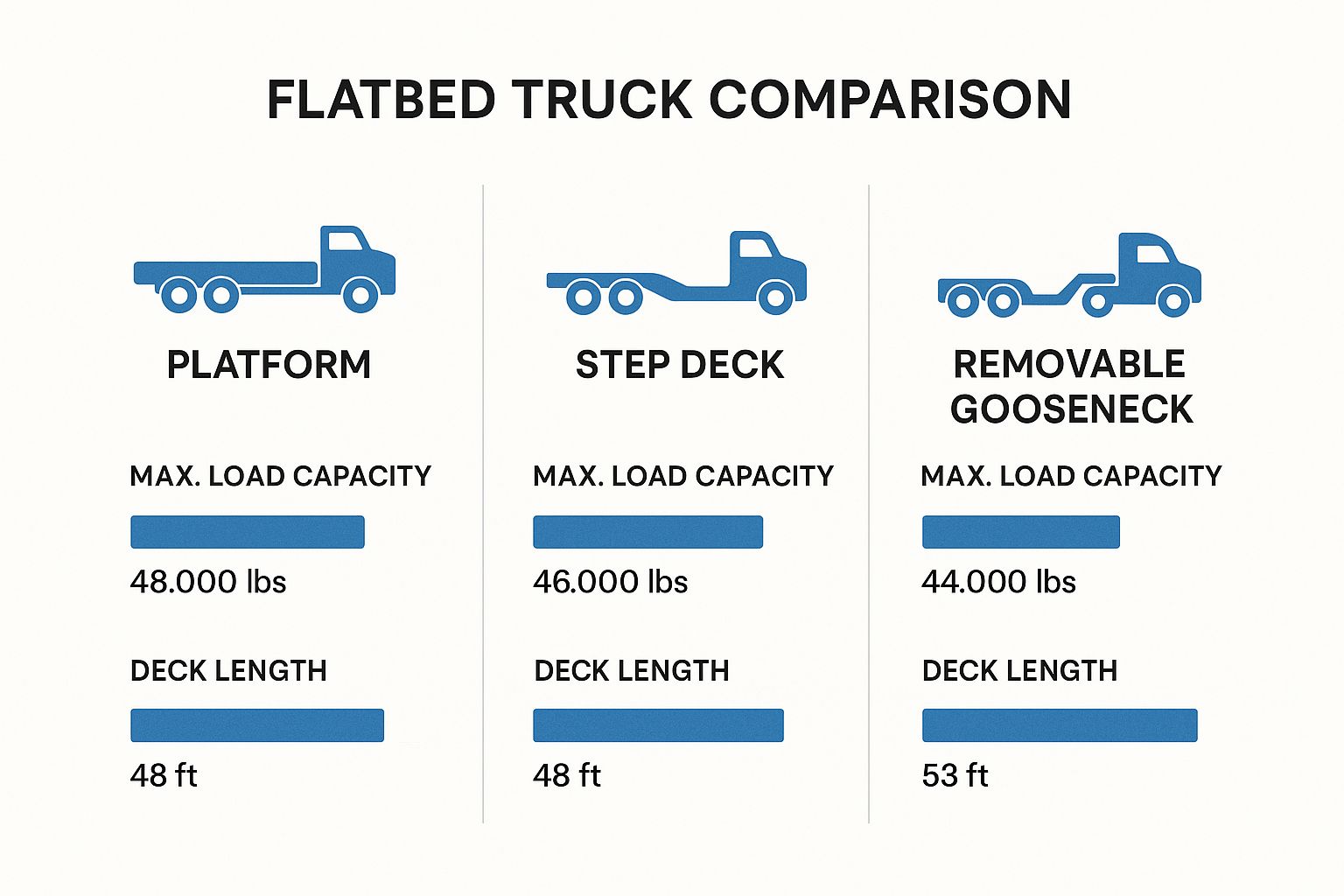

To help you make an informed decision, use this quick-reference table.

Flatbed Trailer Types and Their Ideal Uses

| Trailer Type | Key Feature | Maximum Cargo Height | Common Use Cases |

|---|---|---|---|

| Standard Flatbed | Single, continuous flat deck | 8.5 feet | Building materials, steel, lumber, palletized goods |

| Step-Deck | Two deck levels (upper and lower) | 10 feet | Taller equipment, CNC machines, smaller excavators |

| Double Drop | Lowest deck height, with a "well" in the middle | 11.5 feet | Very tall but not overly heavy items, large tanks |

| RGN | Detachable front for drive-on loading | 11.5+ feet | Heavy, self-propelled equipment like bulldozers, cranes |

This table serves as a practical starting point to match your cargo with the most efficient and appropriate trailer, preventing costly mismatches.

When to Choose Flatbed Truck Transport

Knowing when to opt for a flatbed over an enclosed trailer is crucial for efficient logistics. While standard trailers are perfect for boxed and palletized goods, certain cargo characteristics make an open-deck solution the only viable choice. The decision to use flatbed truck transport typically hinges on three factors: cargo size, shape, or weight.

When Your Freight Won't Fit in the Box

The most common reason for choosing a flatbed is that your freight is oversized. An enclosed trailer has fixed dimensional limits, whereas a flatbed offers open-air flexibility.

Consider these scenarios where a flatbed is non-negotiable:

- Too Long: A 60-foot wind turbine blade cannot fit inside a standard 53-foot trailer. An extendable flatbed is required for such a haul.

- Too Wide: A modular home section, often 14 feet wide or more, far exceeds the 8.5-foot legal width limit of an enclosed trailer.

- Too Tall: Shipping a large combine harvester on a standard-height trailer would create immediate bridge-clearance issues. A lower-deck trailer like a step-deck or double drop is essential.

Handling Awkward Shapes and Heavy-Duty Loads

Beyond simple dimensions, many items are too irregularly shaped or heavy for an enclosed trailer. A flatbed provides the stable, open platform needed for non-standard cargo. For instance, a large cylindrical tank would be unstable inside a van but can be securely cradled and chained on a flatbed. Similarly, heavy construction machinery would exceed the floor weight capacity of a standard trailer.

The demand for moving such equipment continues to grow, reflecting the vital role of flatbed transport in major industries like construction and manufacturing.

The Loading and Unloading Advantage

One of the most significant practical benefits of flatbed shipping is loading and unloading flexibility, especially at locations without a standard loading dock.

Actionable Insight: A flatbed provides 360-degree access, allowing cranes and forklifts to load or unload from the top, sides, or rear. This is indispensable for active construction sites, remote energy fields, or any facility lacking traditional dock infrastructure.

If your delivery point is a job site with no dock, a flatbed is not just a better choice—it's often the only way to deliver the cargo directly where it's needed, avoiding logistical bottlenecks.

Your Step-by-Step Flatbed Shipping Checklist

A methodical approach is the key to a successful flatbed shipment. This checklist breaks down the process into clear, manageable steps, helping you avoid common errors that lead to delays and increased costs.

Step 1: Gather Precise Freight Dimensions

This is the most critical step. Inaccurate measurements are a primary source of shipping problems, from incorrect quotes to the wrong type of trailer arriving for pickup. Before requesting a quote, obtain the exact figures:

- Length: Measure from the absolute longest point to its opposite end.

- Width: Measure between the widest points, accounting for any protrusions.

- Height: Measure from the lowest point to the highest point as it will sit on the trailer.

- Weight: Use a certified scale to get a precise weight. Do not estimate.

These four measurements determine the required trailer type, the viable route, and the need for oversized permits. An error of just a few inches can reclassify a standard shipment as a more complex and expensive permitted load.

Step 2: Prepare Your Cargo for Transit

Flatbed freight is exposed to weather and road debris. You must prepare it for an open-air journey.

Actionable Insight: Proper preparation is your first line of defense against damage. Before the truck arrives, secure loose parts on machinery, drain fluids if necessary, and cover sensitive components. For building materials, bundle or crate them. If your cargo is sensitive to moisture, request tarps from your carrier when you book the shipment.

For detailed guidance, refer to our guide on preparing your heavy equipment for transport.

Step 3: Confirm Loading and Unloading Logistics

The shipper is typically responsible for loading the truck, and the receiver is responsible for unloading it. The driver’s primary role is to secure the load, not to operate loading equipment. Before booking, confirm that both the pickup and delivery locations have the necessary equipment (e.g., forklift, crane) and certified personnel. Miscommunication here can result in significant detention fees if the driver is forced to wait.

Step 4: Secure the Load and Finalize Paperwork

Once the cargo is on the trailer, the driver will secure it using heavy-duty chains, straps, and binders according to strict safety regulations. A key principle is placing approximately 60% of the weight in the front half of the trailer for proper balance and stability. At this point, you will sign the Bill of Lading (BOL). This is a legally binding contract. Carefully review all details—dimensions, weight, addresses, and special instructions—to ensure they are 100% accurate before the truck departs.

Decoding Your Flatbed Shipping Quote

Understanding the components of your flatbed truck transport quote is essential for effective budget management. A quote is a detailed breakdown of costs based on your shipment's specific requirements. Knowing what drives the price allows you to budget accurately and identify potential savings.

Primary Cost Drivers

The core of your quote is determined by a few key factors:

-

Mileage and Route: The total distance is a primary cost factor. However, the specific route is equally important. Transport between major freight hubs is generally less expensive per mile than a route to a remote location due to higher truck availability.

-

Freight Dimensions and Weight: The precise length, width, height, and weight of your cargo are critical. Heavier and larger loads require more fuel, cause more wear on equipment, and may necessitate specialized trailers, all of which increase the price.

-

Permits for Oversized Loads: If your cargo exceeds the legal width of 8.5 feet, it is classified as an "oversized" load. This requires the carrier to obtain special permits for each state on the route. Navigating the regulations for oversize transport permits adds administrative time and direct costs to your quote.

Secondary Factors That Influence Price

Other variables can also affect your final cost:

- Accessorial Charges: Services like tarping to protect freight from weather will incur an additional fee.

- Trailer Type: A standard flatbed is the most economical option. Specialized trailers like RGNs cost more due to their specific capabilities and lower availability.

- Fuel Surcharge: All quotes include a fuel surcharge, a variable fee tied to the national average price of diesel. This protects carriers from fuel price volatility.

Actionable Insight: Regional market conditions impact pricing. Areas with high industrial activity, such as the Southeast and Midwest, have greater truck availability, which can influence rates. Being aware of these market dynamics helps you understand price fluctuations.

Your Top Flatbed Transport Questions, Answered

Navigating a flatbed truck transport shipment can raise questions, even for experienced shippers. Here are answers to some of the most common queries to ensure a smooth process.

How Is My Freight Protected from Rain and Snow?

Protection from the elements is achieved using heavy-duty, industrial-grade vinyl tarps. These are waterproof and tear-resistant. When booking, you must specify that your shipment requires tarping. For highly sensitive cargo, consider crating or shrink-wrapping it before loading as an extra layer of protection against moisture and road debris.

Actionable Insight: Clearly communicate your weather protection needs when requesting a quote. This ensures the carrier dispatches a truck with the correct size and number of tarps, preventing delays and potential damage.

Will I Need a Special Permit for My Shipment?

Yes, if your shipment is 'oversized' or 'over-dimensional.' This applies when your cargo exceeds the legal limits for width (typically 8.5 feet), height (13.5 feet loaded), or length (varies by state). If your freight exceeds these dimensions, your carrier must obtain permits for every state the truck travels through. These permits often come with travel restrictions, such as:

- Daylight-only travel hours.

- No travel on weekends or holidays.

- Required escort vehicles (pilot cars) for exceptionally large loads to ensure public safety.

Moving an oversized load without proper permits results in severe fines and delays. Accurate initial measurements are non-negotiable.

Who Is Responsible for Loading and Unloading the Truck?

This is a critical point of clarity: the shipper is responsible for loading the cargo, and the receiver is responsible for unloading it. The driver’s legal responsibility is to ensure the load is properly secured for transit, not to operate cranes or forklifts. You must confirm that both the origin and destination sites are equipped with the necessary machinery and qualified personnel. Failure to do so can lead to costly detention fees billed by the carrier for wait times.

Whether your load is big or small, having a logistics partner you can count on changes everything. We Will Transport It is an expert at making even the most complex flatbed shipments feel simple and secure. If you’re ready to move your heavy equipment, building supplies, or oversized freight with confidence, get your free, no-obligation quote today. Find out more about our top-notch flatbed truck transport services.